Asphalt regenerant and preparation method thereof

A technology for asphalt regeneration agent and road petroleum asphalt, which is applied in building components, building thermal insulation materials, buildings, etc. Conducive to sustainable development and anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

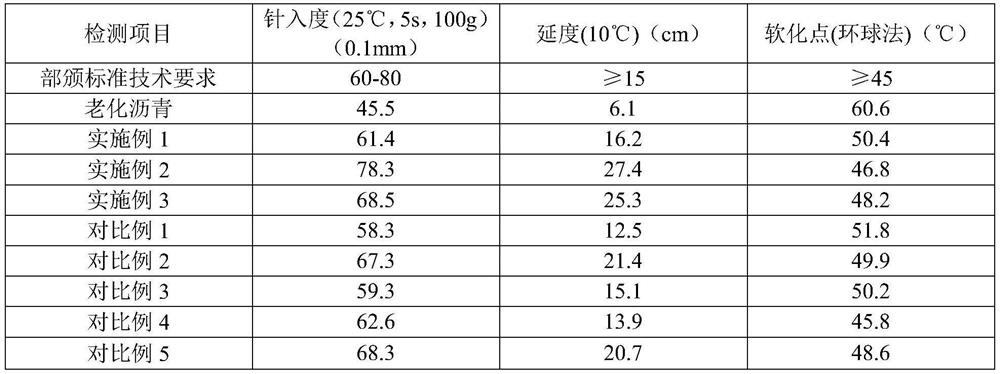

Embodiment 1

[0031] Prepare a kind of asphalt regenerant, the steps are as follows:

[0032] (1) Preheating

[0033] Respectively, 6.5kg of aromatic oil, 3.5kg of waste engine oil residue, and 0.3kg of No. 70 road petroleum asphalt were rapidly preheated to 130°C and stirred evenly before use. Waste lubricating oil residues after centrifugal separation and molecular distillation process;

[0034] (2) ready-mixed and sheared

[0035] Transfer aromatic oil and waste engine oil residues to the high-speed shear pre-mixing system for pre-mixing. The pre-mixing speed is 8r / min, the pre-mixing time is 15min, and the pre-mixing temperature is 130°C. After pre-mixing, add a compatibilizer and send it into the Machine shearing, the shearing rate is 4000r / min, the shearing time is 20min, the shearing temperature is 130°C, and the measured pH value is 5.5;

[0036] (3) Add flame retardant

[0037] Add 0.9 kg of aluminum hydroxide to the mixture after high-speed shearing, and adjust the pH value to...

Embodiment 2

[0039] Prepare a kind of asphalt regenerant, the steps are as follows:

[0040] (1) Preheating

[0041] Respectively, 5.5kg of aromatic oil, 4.5kg of waste engine oil residue, and 0.7kg of No. 70 road petroleum asphalt were rapidly preheated to 140°C and stirred evenly before use. The aromatic oil used was special aromatic oil for reclaimed rubber, and the waste engine oil residue was Waste lubricating oil residues after centrifugal separation and molecular distillation process;

[0042] (2) ready-mixed and sheared

[0043] Transfer aromatic oil and waste engine oil residues to the high-speed shear pre-mixing system for pre-mixing. The pre-mixing speed is 12r / min, the pre-mixing time is 20min, and the pre-mixing temperature is 140°C. After pre-mixing, add a compatibilizer and send it into Machine shearing, the shearing rate is 5000r / min, the shearing time is 30min, the shearing temperature is 140°C, and the measured pH value is 6.3;

[0044] (3) Add flame retardant

[0045...

Embodiment 3

[0047] Prepare a kind of asphalt regenerant, the steps are as follows:

[0048] (1) Preheating

[0049] Respectively, 6.0kg of aromatic oil, 4.0kg of waste engine oil residue, and 0.5kg of No. 70 road petroleum asphalt were quickly preheated to 135°C and stirred evenly before use. The aromatic oil used was special aromatic oil for reclaimed rubber, and the waste engine oil residue was Waste lubricating oil residues after centrifugal separation and molecular distillation process;

[0050] (2) ready-mixed and sheared

[0051] Transfer aromatic oil and waste engine oil residues to the high-speed shear pre-mixing system for pre-mixing. The pre-mixing speed is 10r / min, the pre-mixing time is 20min, and the pre-mixing temperature is 135°C. After pre-mixing, a compatibilizer is added to the Machine shearing, the shearing rate is 4500r / min, the shearing time is 25min, the shearing temperature is 135°C, and the measured pH value is 5.9;

[0052] (3) Add flame retardant

[0053] Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com