Production process and equipment for sanitary stainless steel pipe

A technology of stainless steel pipe and production process, which is applied in the direction of metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., which can solve the problems of reducing use efficiency, slowing down fluid flow rate, fluid retention, etc., so as to improve efficiency and quality, and stabilize activities , The effect of improving the grinding and polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

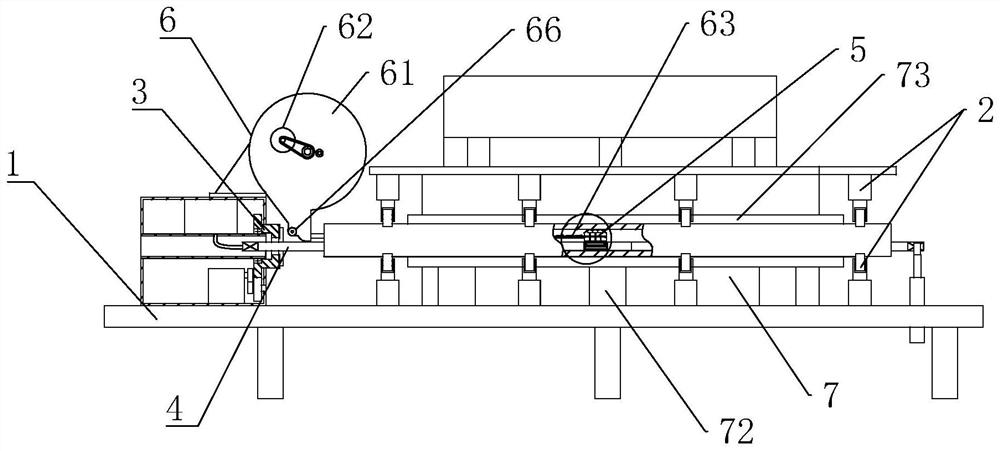

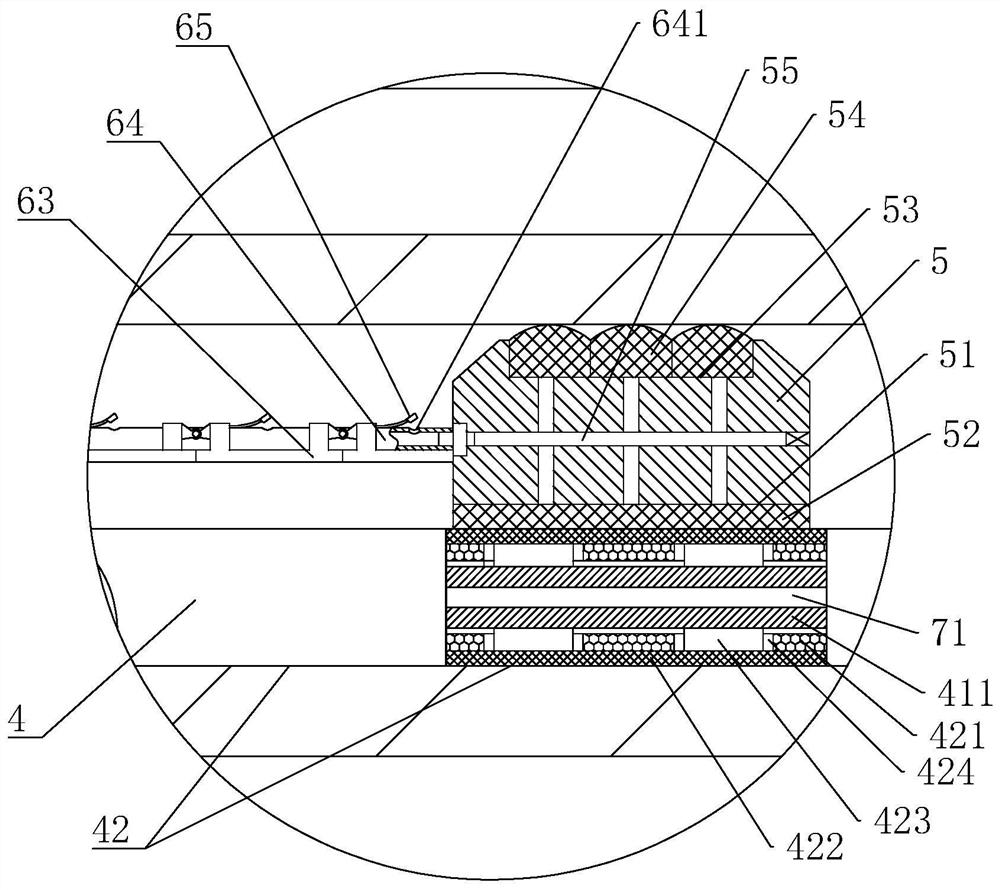

[0032] Attached below Figure 1-2 The present invention is described further:

[0033] With reference to accompanying drawing: the production technology of a kind of sanitary grade stainless steel pipe in the present embodiment, comprises the following steps,

[0034] (1) Forming welding: Send the uncoiled stainless steel to the forming machine; weld the gaps of the formed stainless steel pipes, and use protective gas to cool them during welding; use a grinder to trim the outer surface welds of the welded stainless steel pipes flat;

[0035] (2) Solution annealing: Push the stainless steel pipe after leveling the weld seam into a continuous heating furnace for heating at a temperature of 120°C, then perform non-oxidative heat treatment in a heat treatment furnace at a temperature of 1050°C, and cool it when it comes out of the furnace. The water jacket cools the finished stainless steel pipe, and the outlet temperature of the finished stainless steel pipe is 32°C--38°C;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com