Full-automatic device for terminal processing based on electronic connectors and connectors

An electronic connector, fully automatic technology, used in the manufacture of contacts, the manufacture of contact boxes/bases, etc., can solve the problems of drying or cooling at the point where the glue cannot be dispensed, and achieve the effect of improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

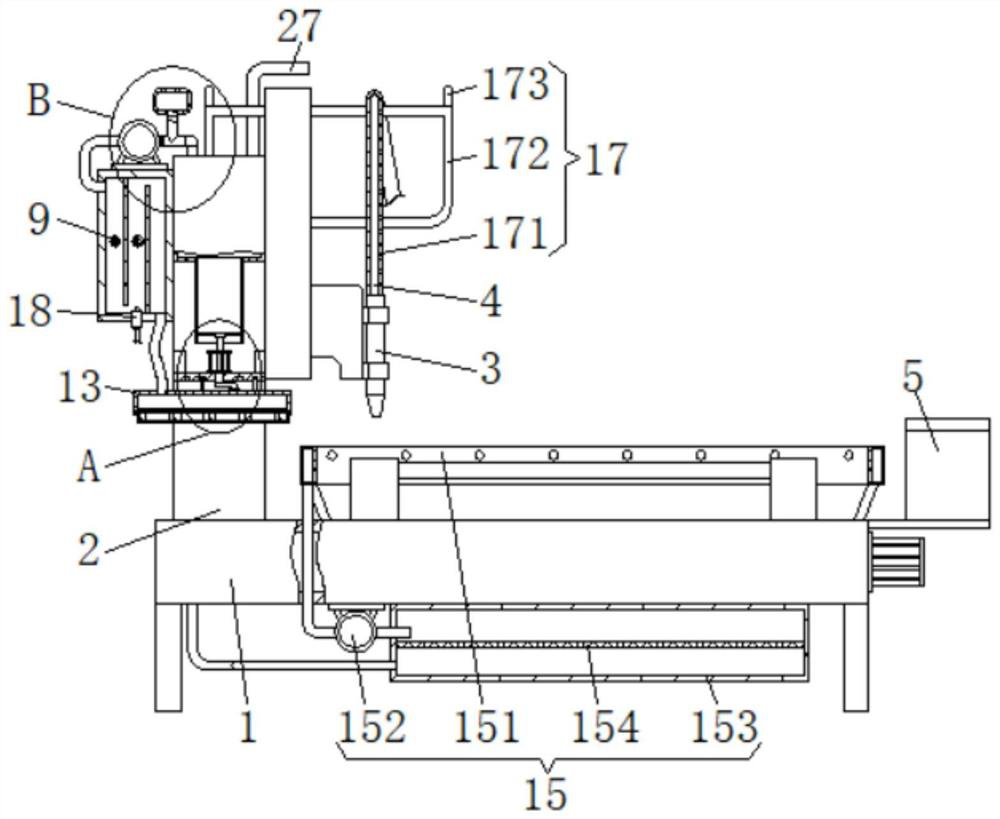

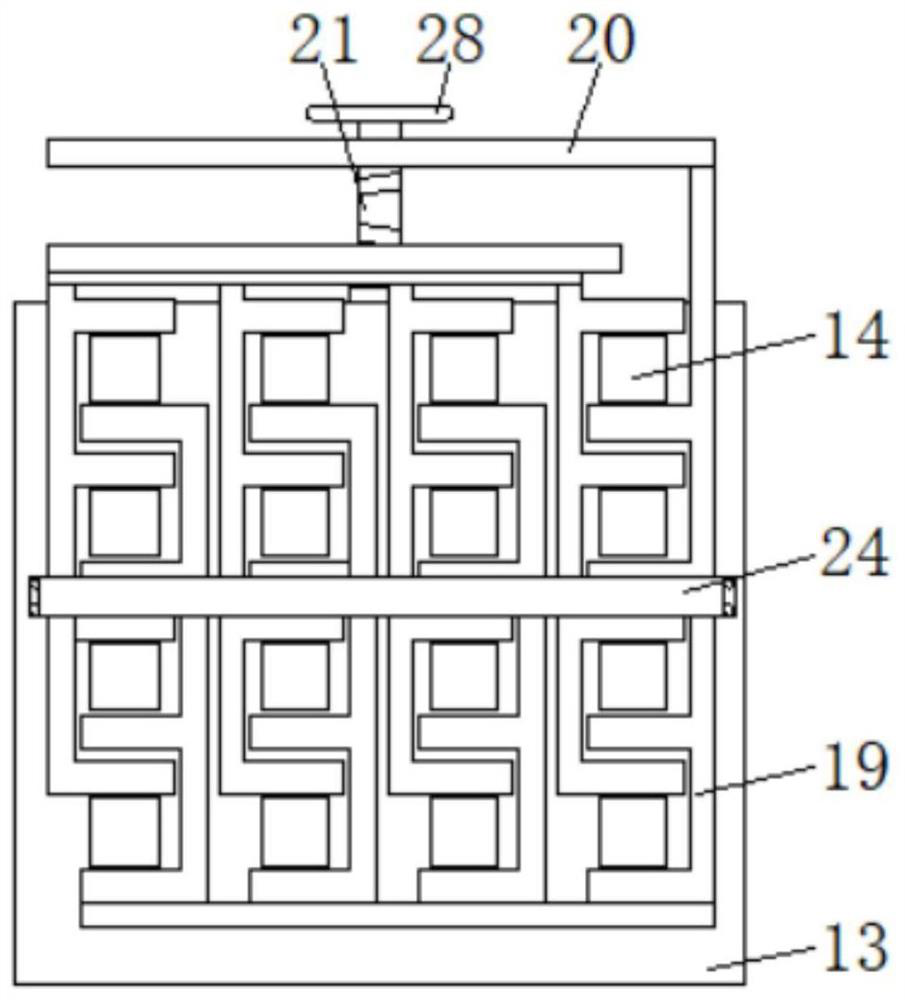

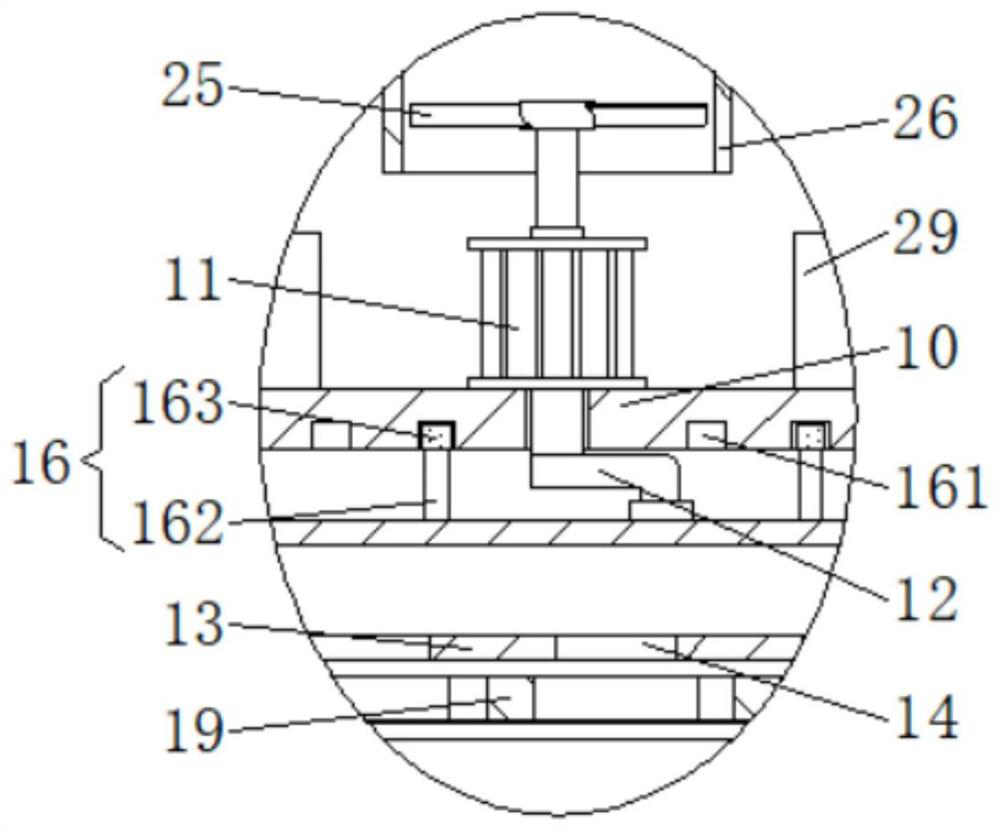

[0028] Embodiment one: if Figure 1 to Figure 5 As shown, the fully automatic equipment based on the processing of electronic connectors and connector terminals provided by the present invention includes a dispensing station 1, a fully automatic dispensing frame 2 is arranged on the left side of the top of the dispensing table 1, and a fully automatic dispensing frame 2 The right side of the dispensing head 3 is fixedly installed, the top of the dispensing head 3 is connected to the dispensing tube 4, the right side of the dispensing table 1 is fixedly connected to the control device 5, and the left side of the automatic dispensing frame 2 is fixedly connected to the heating box 6. The left side of the top of the heating box 6 is connected with a blower 7, the inside of the heating box 6 is fixedly connected with a partition 8 vertically, the inside of the heating box 6 is fixedly connected with a heating pipe 9 horizontally, and the inside of the automatic dispensing frame 2 i...

Embodiment 2

[0052] Embodiment two: if Image 6 As shown, in the second embodiment, other structures remain unchanged. The present invention provides another structural form of the sliding bar 262 to solve the problem that the L-shaped bar 12 is prone to damage. The sliding bar 262 includes a trapezoidal bar 2621, a ball 2622 And the trapezoidal ring groove 2623, the trapezoidal rod 2621 is fixedly connected on both sides of the top of the spray sleeve 13, the ball 2622 is movably embedded in the inside of the trapezoidal rod 2621, the trapezoidal ring groove 2623 is opened on both sides of the bottom of the backing plate 10, the trapezoidal rod 2621 and the ball 2622 are movably connected inside the trapezoidal ring groove 2623; the trapezoidal rod 2621 can support the spray sleeve 13 through the ball 2622 and the trapezoidal ring groove 2623, avoiding the phenomenon that the spray sleeve 13 is only supported by the trapezoidal rod 2621, in this embodiment Second, in order to improve the ...

Embodiment 3

[0053] Embodiment three: as Figure 7 As shown, in the third embodiment, other structures remain unchanged. The present invention provides another structural form of the screw 211 to solve the problem that the user manually adjusts the grid plate 19 and the adjustment efficiency is low. The screw 211 includes a motor 2111 , the vertical screw rod 2112 and the distance sensor 2113, the motor 2111 is fixedly connected to the front of the spray sleeve 13, the vertical screw rod 2112 is fixedly connected to the output end of the motor 2111, and the transmission plate 20 is screwed to the surface distance of the vertical screw rod 2112 The sensor 2113 is fixedly connected to the right side of the drive plate 20, and the distance sensor 2113 is located on the right side of the vertical screw 2112; the motor 2111 can quickly and accurately adjust the grid plate 19 through the vertical screw 2112 and the distance sensor 2113, and it is convenient The user can observe the adjustment di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com