Image segmentation method for tail section pore feature extraction of sintering machine

A feature extraction and image segmentation technology, which is applied in image analysis, image enhancement, image data processing, etc., can solve the problem of inaccurately obtaining the proportion of air holes, etc., so as to liberate the environmental operation of the tail section, extract accurate image features, reduce workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

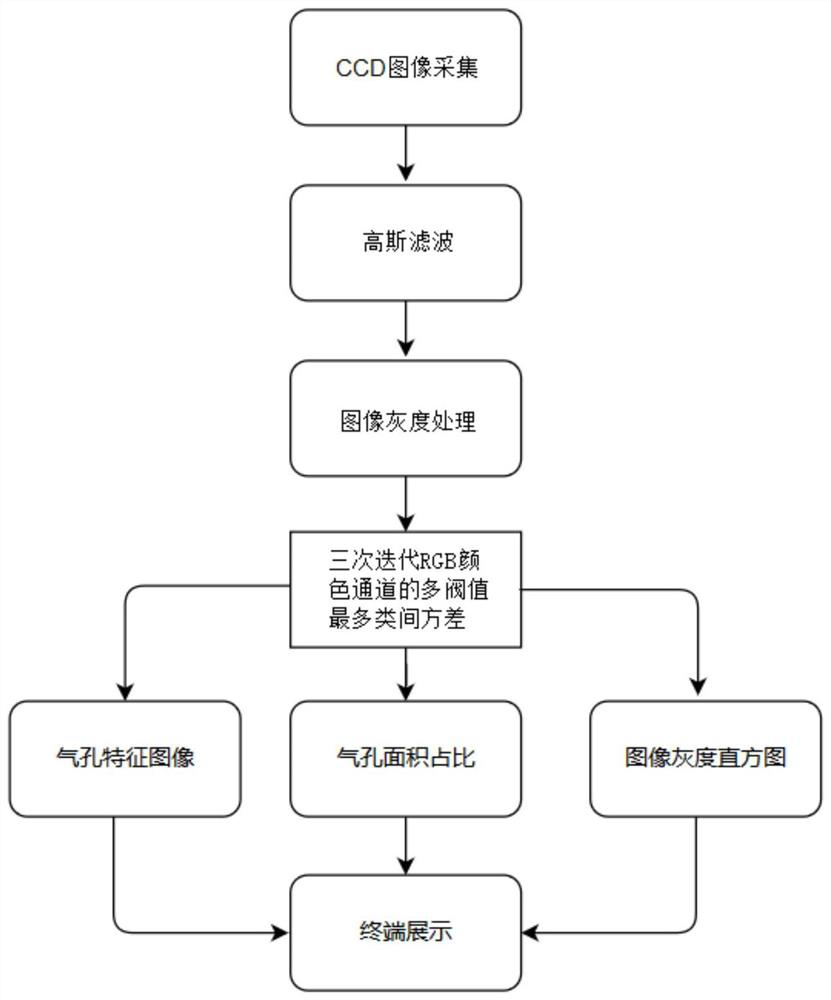

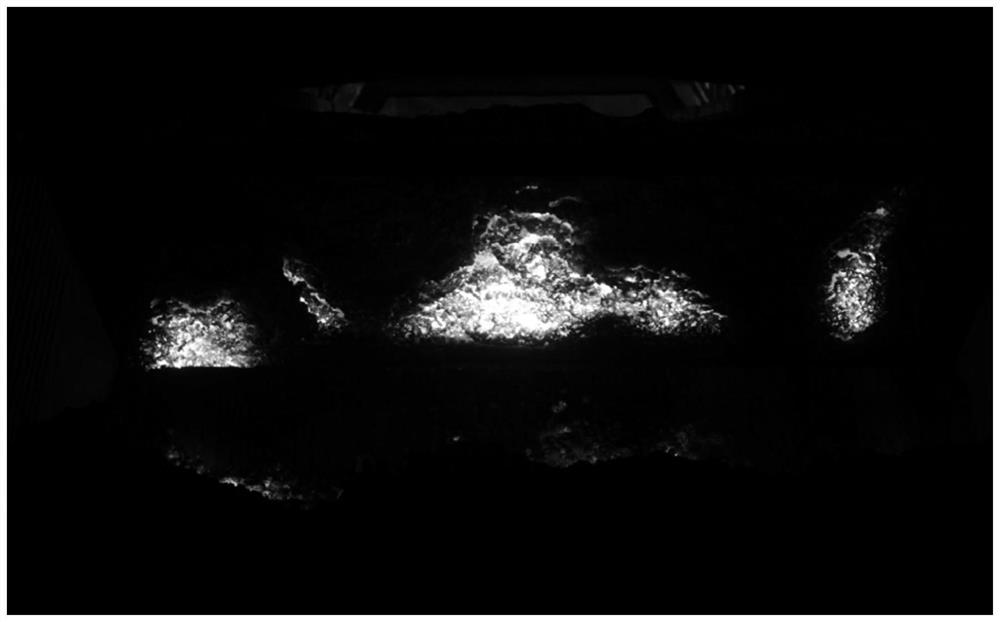

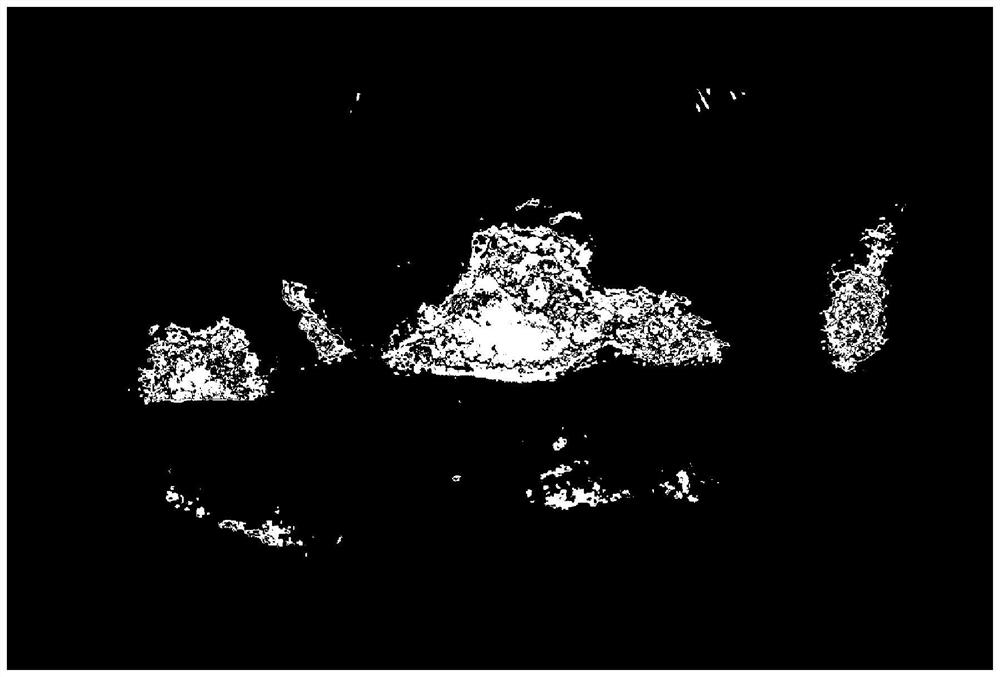

[0075] Such as figure 1 As shown, in this embodiment, the CCD image acquisition unit is first used to collect the cross-sectional image of the tail of the sintering machine; then the image is processed by the computer, and the cross-section of the tail of the sintering machine is subjected to Gaussian filter denoising, image grayscale processing, and three iterations of RGB color channels. The multi-threshold maximum inter-class variance method is used to process the image. Through image processing and analysis, the sintering machine tail section segmentation processed air hole feature image, the area ratio of air holes and the segmented tail section gray histogram are obtained. The CCD visible light image acquisition unit may be a color CCD visible light camera.

[0076] Taking a certain number of sintering machine in a steel factory as an example, it will be described in detail, combined with figure 1 , the specific process is as follows:

[0077] Step 1. At a distance of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com