Regenerated garbage bag prepared from waste plastics and preparation method thereof

A technology of garbage bags and waste plastics, which is applied in the field of resource utilization of waste plastics, can solve the problems of no recycling value, difficult to degrade, and difficult to deal with plastic pollution, and achieve the effects of excellent performance, small environmental impact, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

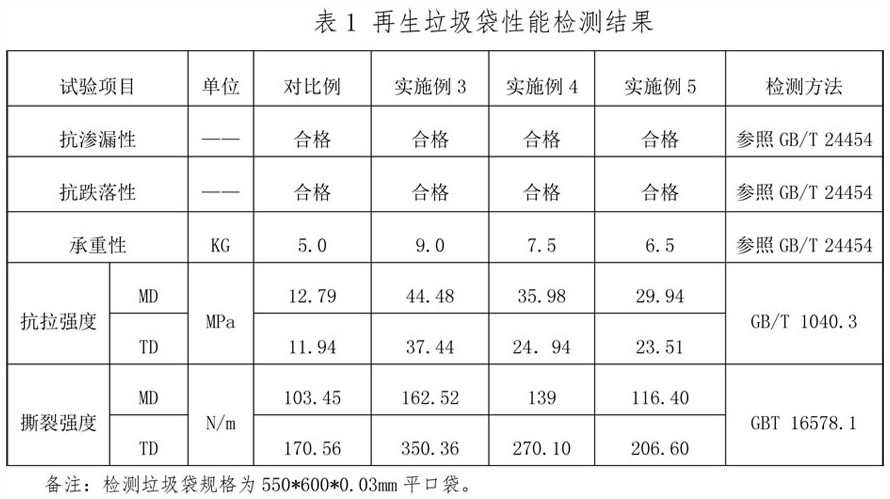

Examples

preparation example Construction

[0052] A method for preparing a recycled garbage bag prepared from waste plastics, comprising the following steps:

[0053] Step 1: weighing 30-70 parts of recycled high-density polyethylene, 0-40 parts of high-density polyethylene, 0-20 parts of recycled low-density polyethylene, 0-20 parts of low-density polyethylene, 10-30 parts of linear low density polyethylene, 0-8 parts of color masterbatch and 1-5 parts of open-ended masterbatch, mix each raw material component in a high-speed mixer for 5-15 minutes to obtain a premix;

[0054] Step 2: Use an automatic feeding device to feed the premix into the extruder for melting, mixing, and plasticization. The barrel temperature of the extruder is 160-250°C;

[0055] Step 3: The plasticized melt enters the annular die of the extruder head to form a cylindrical film tube, and the temperature of the head is 170-250°C;

[0056] Step 4: Blow compressed air into the film tube to make it expand, then air-cool, pull, and roll to form a f...

Embodiment 1

[0060] The material of the regenerated garbage bag comprises the following raw material parts by weight in the present embodiment:

[0061] 30 parts of recycled high-density polyethylene (r-HDPE)

[0062] High-density polyethylene (HDPE) 35 parts

[0063] Recycled low-density polyethylene (r-LDPE) 10 parts

[0064] Low-density polyethylene (LDPE) 0 parts

[0065] Linear low density polyethylene (LLDPE) 25 parts

[0066] Color masterbatch 5 parts

[0067] Open masterbatch 2 parts

[0068] The melt mass flow rate of recycled high-density polyethylene (r-HDPE) is 0.4g / 10min; the melt mass flow rate of high-density polyethylene (HDPE) is 0.035g / 10min; the recycled low-density polyethylene (r-LDPE) ) The melt mass flow rate is 0.34 g / 10min; the linear low density polyethylene (LLDPE) melt mass flow rate is 1.0g / 10min; the masterbatch is black, and its carrier resin is LDPE, and its melt mass The flow rate is 2.0 g / 10min; the carrier resin of the open masterbatch is LDPE.

[...

Embodiment 2

[0076] The material of the regenerated garbage bag comprises the following raw material parts by weight in the present embodiment:

[0077] Recycled high-density polyethylene (r-HDPE) 50 parts

[0078] High-density polyethylene (HDPE) 20 parts

[0079] Recycled low-density polyethylene (r-LDPE) 0 parts

[0080] Low-density polyethylene (LDPE) 10 parts

[0081] Linear Low Density Polyethylene (LLDPE) 20 parts

[0082] Color masterbatch 5 parts

[0083] Open masterbatch 1 part

[0084] The melt mass flow rate of recycled high-density polyethylene (r-HDPE) is 0.4g / 10min; the melt mass flow rate of high-density polyethylene (HDPE) is 0.035g / 10min; the melt mass flow rate of low-density polyethylene (LDPE) The flow rate is 2.4g / 10min; the melt mass flow rate of linear low-density polyethylene (LLDPE) is 1.0g / 10min; the masterbatch is black color masterbatch, the carrier resin is LDPE, and the melt mass flow rate is 2.0 g / 10min; open masterbatch carrier resin is LDPE / LLDPE.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com