TPU color-changing film production device and production method

A production device and technology of color film, applied in applications, household appliances, flat products, etc., can solve the problems that single-layer color film cannot meet the individual needs of customers, increase enterprise costs, and tear the melted film, etc., to improve gas Spill performance, improve blanking efficiency, effect of changing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0030] The present invention provides a technical solution:

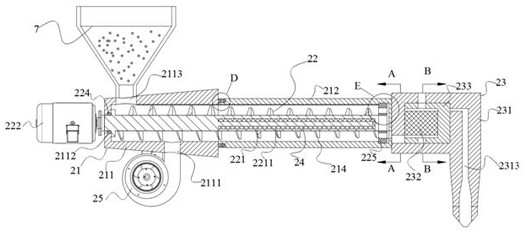

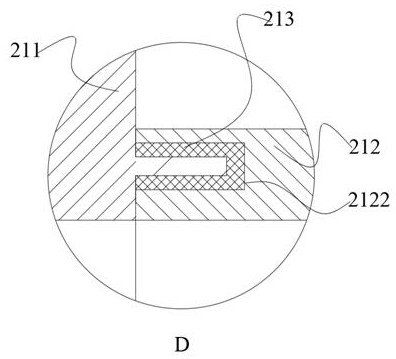

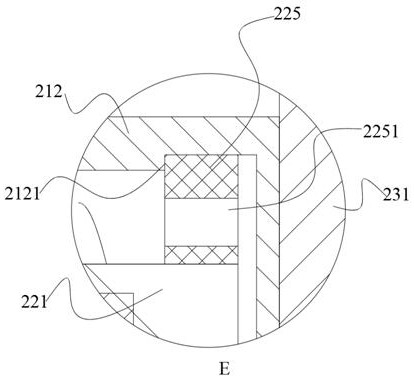

[0031] like Figure 1 ~ 2 As shown, a TPU color filter film production apparatus, characterized in that the color filter film production apparatus includes a fixing device 1, and a molding device 2, a cooling device 3, an upper rubber device 4, and a bonding device 5 are sequentially provided. The device 2 and the fixing device 1 are fastened, and the molding device 2 is provided with two groups, the cooling device 3 and the fixing device 1 are tightened, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com