Rapid identification method for macro-cell corrosion control modes of reinforcing steel bars in marine concrete

A marine concrete and corrosion control technology, which is applied in the fields of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve the problems of many electrochemical parameters and complicated judgment process, and achieve simplified judgment process, convenient detection operation, The effect of the analysis process is simple and clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

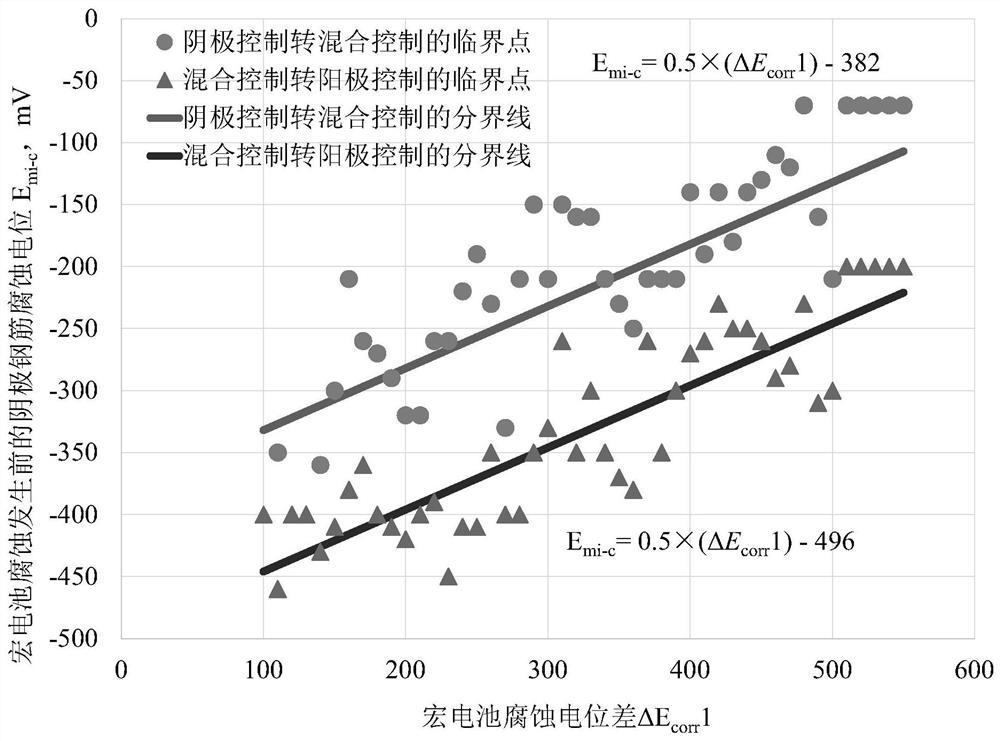

[0023] Firstly, the macro cell corrosion test is carried out to determine the macro cell corrosion control mode. Concrete structures are poured and formed, the concrete strength grade is not less than C30, the water-binder ratio is not more than 0.55, the amount of mineral admixtures is less than 60% of the total amount of cementitious materials, and the thickness of the protective layer of steel bars in the concrete structure is not less than 40mm. Change the content of chloride ions in concrete by directly adding chloride ions during mixing and infiltrating chloride ions from the outside after hardening, so that the cathode steel bars and the anode steel bars exhibit different electrochemical parameters in order to simulate different macro cell corrosion state.

[0024]In the concrete structure, the area ratio of the cathode reinforcement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com