Silk protein-based flexible composite sensor and preparation method thereof

A composite sensor and silk protein technology, applied in the field of sensors, can solve problems such as difficulty in returning the resistance value to the initial value, inability to sense temperature, unstable resistance value, etc., to achieve environmental protection, reduce material consumption, and increase lifespan Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

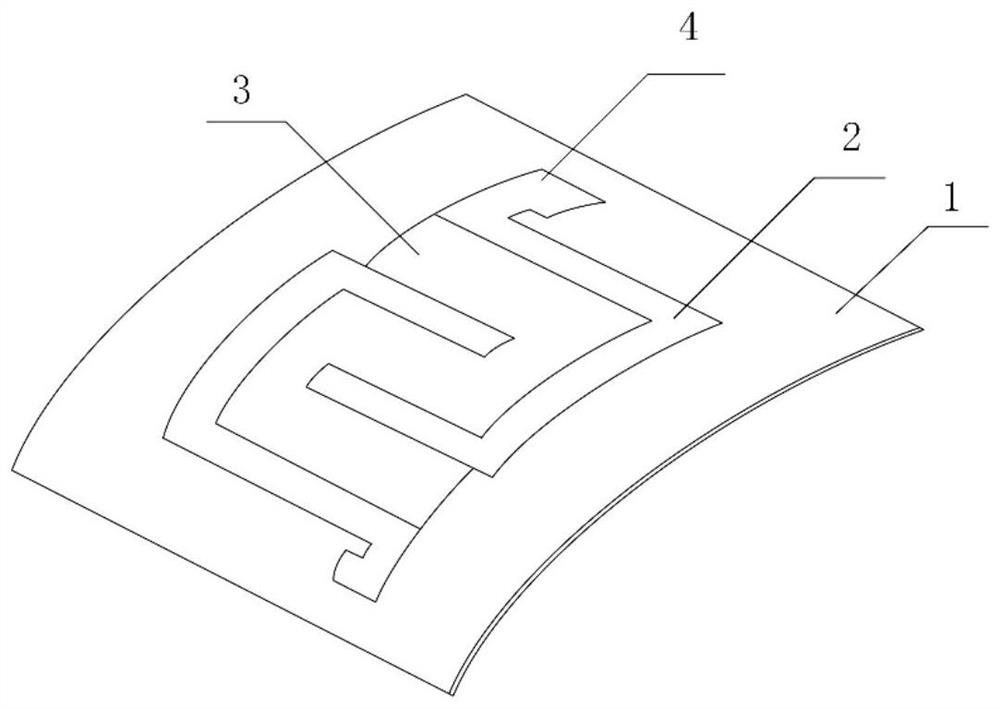

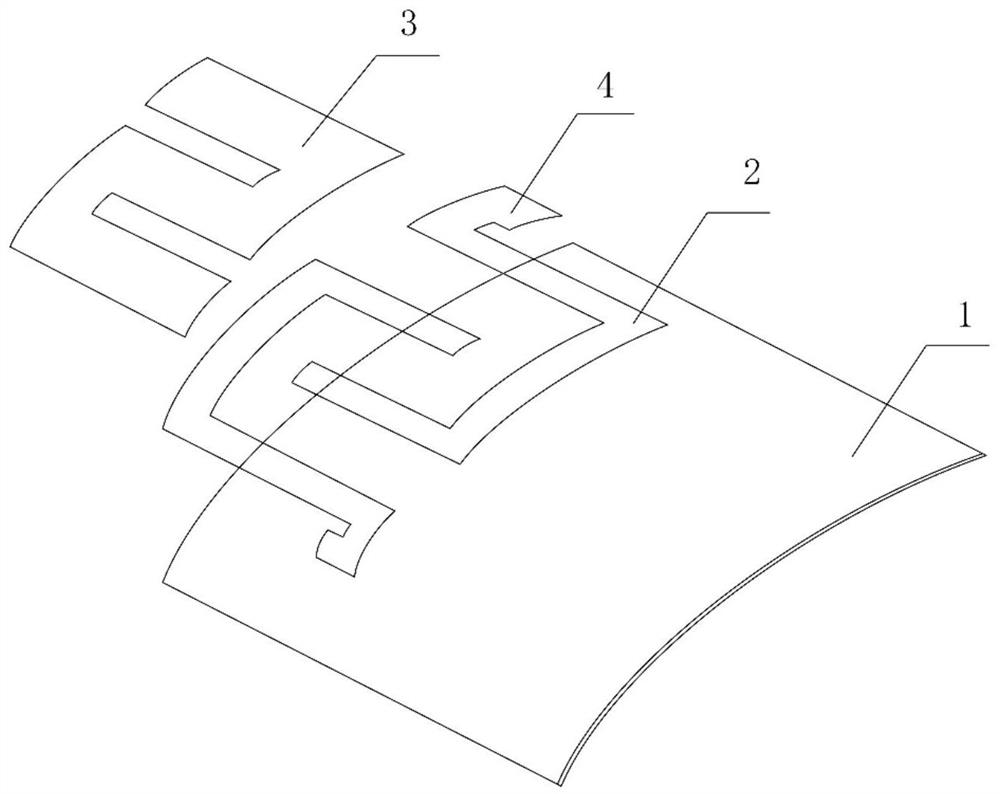

[0050] Such as Figure 1 to Figure 2 As shown, the present invention provides a flexible composite sensor based on silk protein, comprising: a flexible substrate 1, interdigital electrodes 2 and folded composite sensing materials 3, and the interdigitated electrodes 2 are located on the flexible substrate 1 and folded composite sensing materials Between 3, the folded composite sensing material 3 is silk protein and graphene film. Wherein, the material of the flexible base 1 is silk protein film and calcium ion film, the mass fraction of silk protein is 57wt%-80wt%, and the mass fraction of calcium ion is 20wt%-43wt%. The conductive substance used in the interdigital electrode 2 is one of conductive silver paste, conductive copper paste and conductive silver ink; the interdigital electrode 2 is provided with an electrode lead-out area 4, and the area of the electrode lead-out area 4 is 2*2mm 2 The interdigital electrode 2 is provided with a gap that completely matches the fo...

Embodiment 2

[0062] A method for preparing a flexible composite sensor based on silk protein, comprising the following steps:

[0063] S1. Preparation of flexible substrate: Print the designed mold with a 3D printer, pour polydimethylsiloxane polymer or silica gel into the mold and pour the mold, and then pour the silk protein solution into the poured mold for a second time Invert the mold to obtain a flexible substrate 1 .

[0064] Specifically, first draw the mold through SOLIDWORKS drawing software, and the peripheral size of the mold is 60*60*3.5mm 3 , slot size 50*50*1mm 3 , and then print the mold through a high-precision 3D printer, and finally pour polydimethylsiloxane polymer (PDMS) or silica gel into the mold and pour the mold, and then pour the silk protein solution into the poured mold. Invert the mold for the second time and put it in an oven at 40°C for curing.

[0065] S2. Preparation of interdigitated electrodes: Print conductive silver paste or conductive silver ink on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com