Intelligent stepless air regulating valve

A stepless air and regulating valve technology, applied in the field of regulating valve manufacturing, can solve the problems of poor linearity and regulating accuracy, and achieve the effects of good regulating linearity, convenient installation and use, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

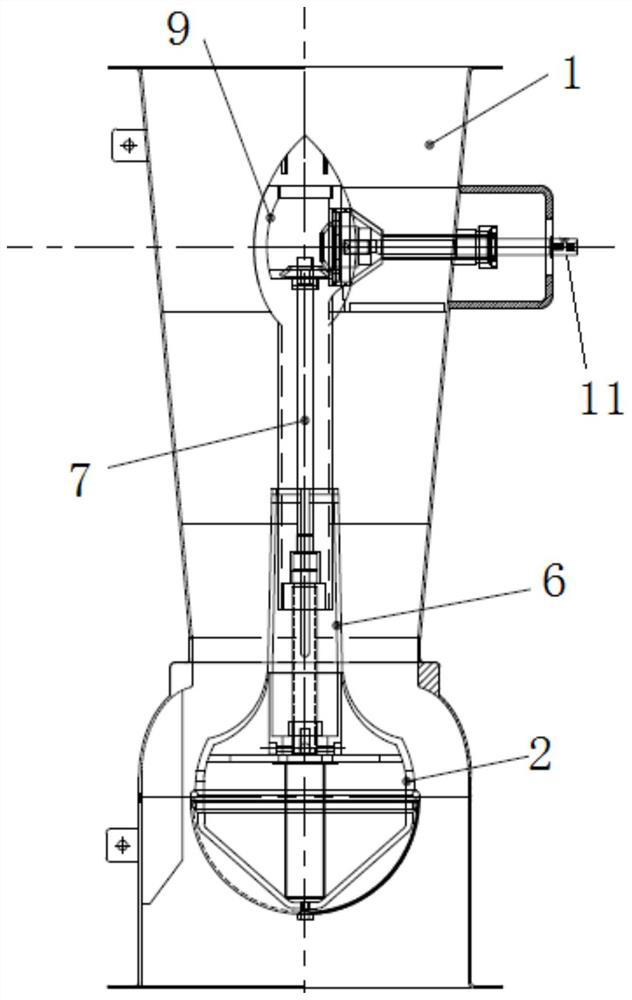

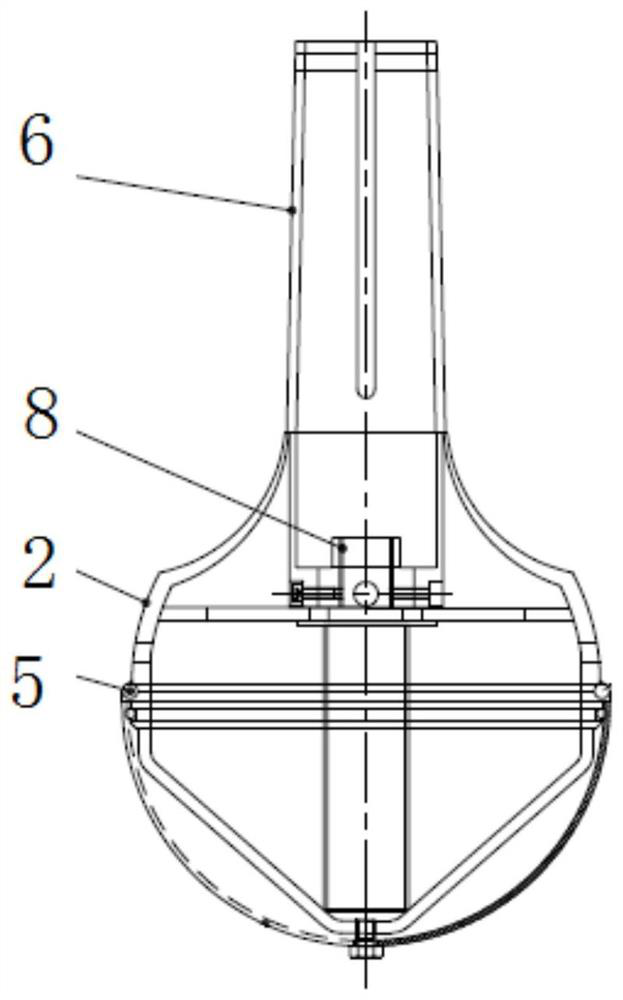

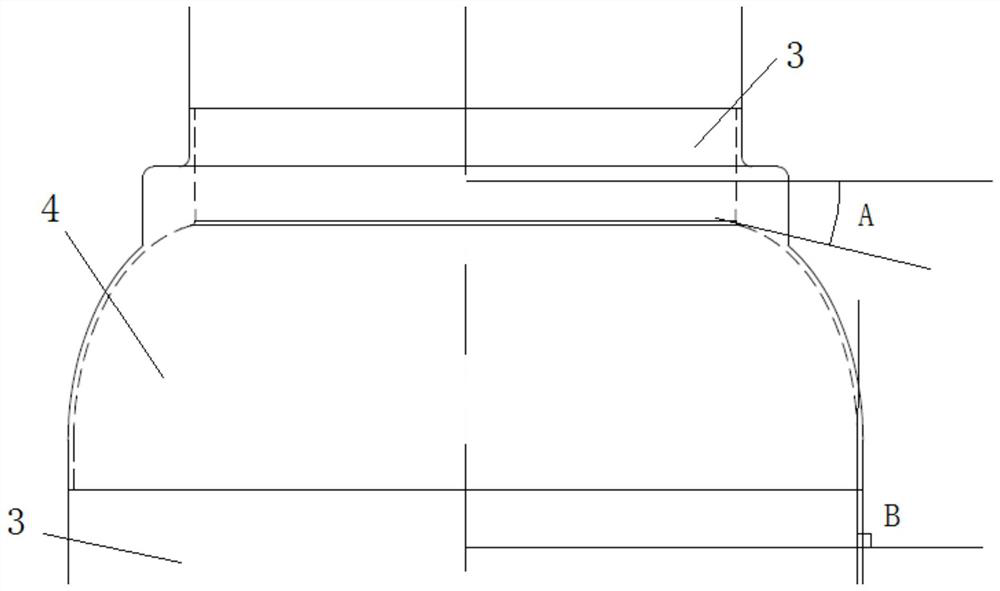

[0040] like Figure 1 to Figure 4 As shown, the intelligent stepless air control valve includes a valve body 1 and a valve core 2 installed in the valve body 1; it is characterized in that the inner cavity of the valve body 1 is in the shape of a stepped tube, including two coaxial sections with different inner diameters. Circular straight tube structure 3;

[0041] Two sections of circular straight pipe structures 3 are communicated through a streamlined inner cavity 4 whose generatrix is an arc;

[0042] The axis of the streamlined inner cavity 4 is coaxial with the axes of the two circular straight pipe structures 3;

[0043] At the connection position between the streamlined inner chamber 4 and the circular straight pipe structure 3 with a smaller inner diameter, the included angle A between the tangent of the generatrix of the streamlined inner chamber 4 and the radial direction of the circular straight pipe structure 3 with a smaller inner diameter is 0 degrees to 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com