Seedling-raising substrate and seedling-raising pot made therefrom

A technology for raising seedling substrate and mass fraction is applied in the field of seedling raising pots, which can solve problems such as limited sources of seedling raising substrate, and achieve the effects of improving recycling value, solving difficulty in borrowing soil, and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

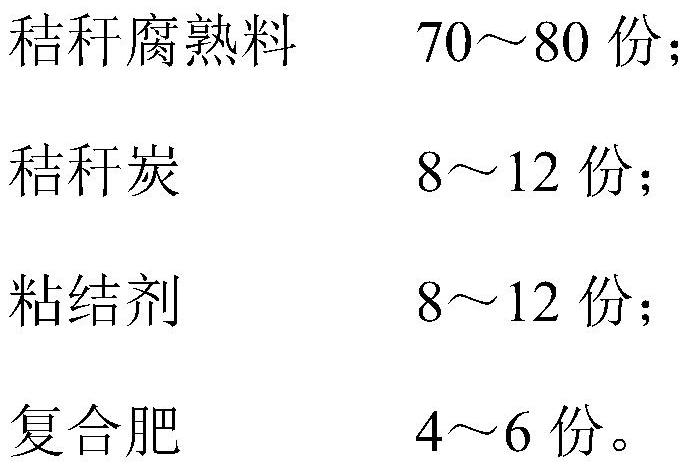

[0031] This embodiment provides a seedling raising substrate, the raw materials of which include 75g of corn stalk clinker, 10g of corn stalk charcoal, 10g of polyvinyl alcohol, 323g of water, and 5g of compound fertilizer. The preparation process is as follows: (1) mix 10g of polyvinyl alcohol with 323g of water to prepare a polyvinyl alcohol aqueous solution with a mass fraction of 3%; (2) mix 75g of corn stalk clinker, 10g of corn stalk charcoal, 5g of compound fertilizer and The above polyvinyl alcohol aqueous solution is uniformly mixed to obtain the seedling raising substrate.

[0032] Wherein, the preparation process of the corn stalk decomposed clinker is as follows: crush the corn stalks to obtain straw powder, mix the straw powder with yeast, compound fertilizer and water in a mass ratio of 100:0.05:0.6:48, stack, and use a film Seal it tightly and keep it moist. After the temperature reaches 50°C, turn the pile once every 7-10 days in spring, summer and autumn, and ...

Embodiment 2

[0035] This embodiment provides a seedling raising substrate, the raw materials of which include 70 g of rice straw decomposed material, 8 g of rice straw charcoal, 8 g of sodium carboxymethyl cellulose, 392 g of water, and 4 g of compound fertilizer. The preparation process is as follows: (1) mixing 8 g of sodium carboxymethyl cellulose with 392 g of water to prepare an aqueous solution of sodium carboxymethyl cellulose with a mass fraction of 2%; (2) mixing 70 g of rice straw decomposed clinker, 8 g of rice straw Charcoal, 4g of compound fertilizer and the above-mentioned sodium carboxymethylcellulose aqueous solution are mixed evenly to obtain the seedling-raising substrate.

[0036] Wherein, the preparation process of the rice straw decomposed clinker is as follows: pulverize rice straw to obtain straw powder, mix the straw powder with yeast, compound fertilizer and water at a mass ratio of 100:0.02:0.5:45, stack, and cover with film Seal tightly and keep moisture. After t...

Embodiment 3

[0039]This embodiment provides a seedling raising substrate, the raw materials of which include 40g of cotton straw decomposed material, 40g of wheat straw decomposed material, 12g of wheat straw charcoal, 12g of guar gum, 288g of water, and 6g of compound fertilizer. The preparation process is as follows: (1) mixing 12g of guar gum with 288g of water to prepare an aqueous solution of guar gum with a mass fraction of 4%; (2) mixing 40g of cotton straw decomposed clinker, 40g of wheat straw decomposed clinker, and 12g of wheat straw Charcoal, 6g compound fertilizer and the above-mentioned guar gum aqueous solution are mixed uniformly to obtain the described seedling-raising substrate.

[0040] Wherein, the preparation process of the cotton straw decomposed clinker and wheat straw decomposed clinker is: crush cotton straw or wheat straw to obtain straw powder, and mix straw powder with yeast, compound fertilizer and water in a mass ratio of 100:0.08:0.8:50 Mix, stack, and seal w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com