Straw biomass seedling raising tray and preparation method thereof

A technology for biomass and seedling trays, applied in fertilizer mixtures, organic fertilizers, nitrogen fertilizers, etc., can solve problems such as poor water permeability and air permeability, and achieve the effects of enhancing disease resistance, improving utilization rate and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

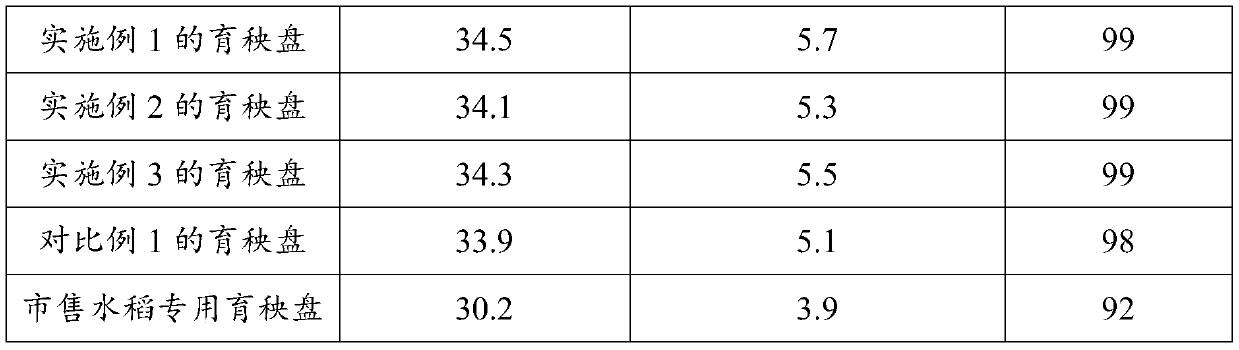

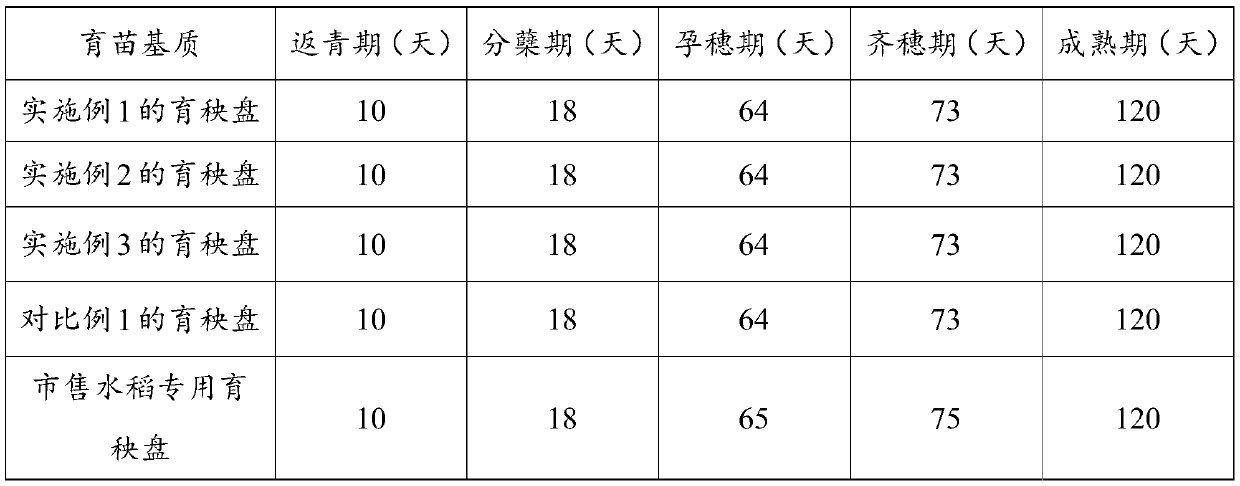

Embodiment 1

[0029] This embodiment provides a straw biomass seedling raising tray, the raw material composition of which is: 100 kg of fermented corn straw; 10 kg of water; 1 kg of wood vinegar, and 0.2 kg of carbon-based fertilizer.

[0030] Wherein, the preparation method of the fermented product of corn stalks is as follows: dry the corn stalks until the water content is 30wt%, pulverize the corn stalks to obtain powdered corn stalks, mix the corn stalks powder and straw decomposing agent evenly in a mass ratio of 100:0.05, After 7 days of decomposing treatment, the fermented product of corn stalks was obtained.

[0031] Biochar is a solid product obtained by pyrolyzing corn stalks under 450°C oxygen-limited conditions; wood vinegar is a liquid product obtained by pyrolyzing corn stalks under 450°C oxygen-limited conditions.

[0032] The carbon-based fertilizer is prepared by mixing, pulverizing and granulating the above-mentioned biomass charcoal, nitrogen fertilizer, phosphorus ferti...

Embodiment 2

[0038] This embodiment provides a straw biomass seedling raising tray, the raw materials of which are as follows: 90 kg of fermented rice straw; 9 kg of water; 1 kg of wood vinegar, and 0.2 kg of charcoal-based fertilizer.

[0039] Wherein, the preparation method of the fermented product of rice straw is: drying the rice straw until its water content is 20wt%, pulverizing the rice straw powder, mixing the rice straw powder and a straw decomposing agent at a mass ratio of 100:0.02, and decomposing After 10 days of treatment, a fermented product of rice straw was obtained.

[0040] Biochar is a solid product obtained by pyrolyzing rice straw under 300°C oxygen-limited conditions; wood vinegar is a liquid product obtained by pyrolyzing rice straw under 300°C oxygen-limited conditions.

[0041]The carbon-based fertilizer is prepared by mixing, pulverizing and granulating the above-mentioned biomass charcoal, nitrogen fertilizer, phosphorus fertilizer and potassium fertilizer accor...

Embodiment 3

[0047] This embodiment provides a straw biomass seedling raising tray, the raw materials of which are: 110 kg of fermented wheat straw; 12 kg of water; 1 kg of wood vinegar, and 0.2 kg of carbon-based fertilizer.

[0048] Wherein, the preparation method of the wheat straw fermented product is: dry the wheat straw until its water content is 40wt%, pulverize the wheat straw powder, mix the wheat straw powder and the straw decomposing agent according to the mass ratio of 100:0.08, After 12 days of decomposing treatment, the fermented wheat straw was obtained.

[0049] Biochar is a solid product obtained by pyrolyzing wheat straw under oxygen-limited conditions of 700°C; wood vinegar is a liquid product obtained by pyrolyzing wheat straw under oxygen-limited conditions of 600°C.

[0050] The carbon-based fertilizer is prepared by mixing, pulverizing and granulating the above-mentioned biomass charcoal, nitrogen fertilizer, phosphorus fertilizer and potassium fertilizer according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com