Crosslinked vinyl acetate-acrylic block copolymer emulsion type dust suppressant and preparation method thereof

A technology of vinyl acetate and block copolymers, which is applied in the field of environmental pollution control, can solve problems such as uneven distribution of hydrophilic groups, fragile film formation, and brittle film formation, and achieve good water solubility and storage stability. Improvement of strength and toughness, effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

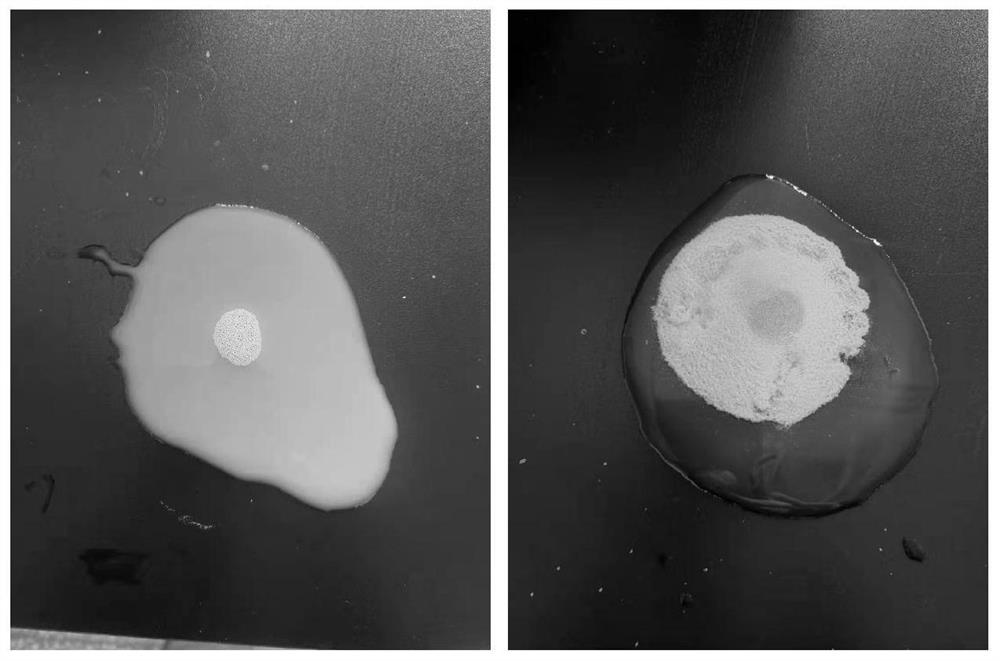

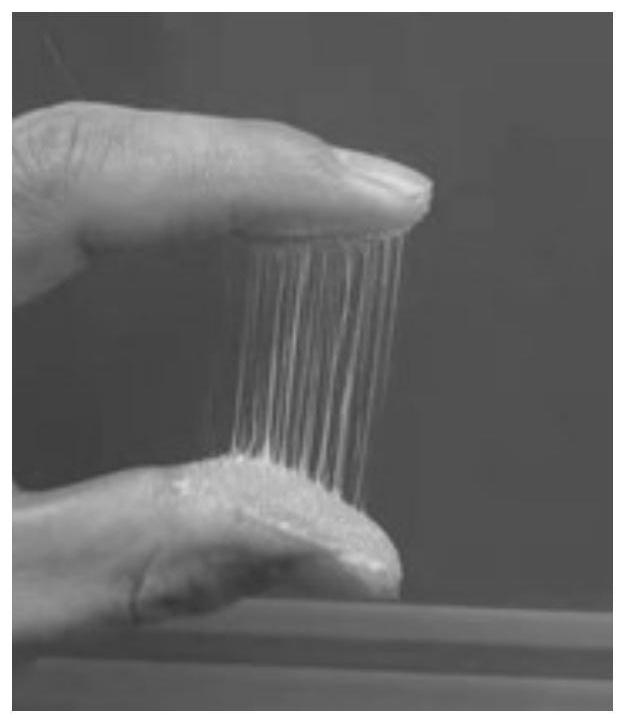

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0033] The present invention is described in detail below through the following examples.

[0034] This embodiment first relates to a cross-linked vinyl acetate-acrylic acid block copolymer emulsion type dust suppressant (hereinafter referred to as dust suppressant JYBQ). In terms of overall design, the preparation of the dust suppressant JYBQ includes vinyl acetate and acrylic acid As a monomer, potassium persulfate and / or ammonium persulfate are initiators, OP10 is an emulsifier, and the F21312 type high-efficiency dispersant prepared by Shijiazhuang Jinguang Technology Co., Ltd. is a dispersant, prepared by Shijiazhuang Jinguang Technology Co., Ltd. J21312 high-efficiency cross-linking agent, prepared by emulsion polymerization.

[0035] Wherein, the dosage of each of the above components (by volume frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com