A kind of easy-to-clean ceramic tile and preparation method thereof

A ceramic tile and easy-to-clean technology, which is applied in the field of ceramic tiles, can solve the problems of scratches on the surface of ceramic tiles, poor user experience, and difficulty in wiping clean, and achieves the advantages of easy cleaning, good pollution resistance, and enhanced wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

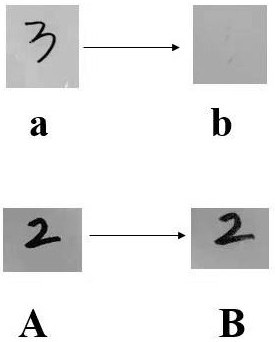

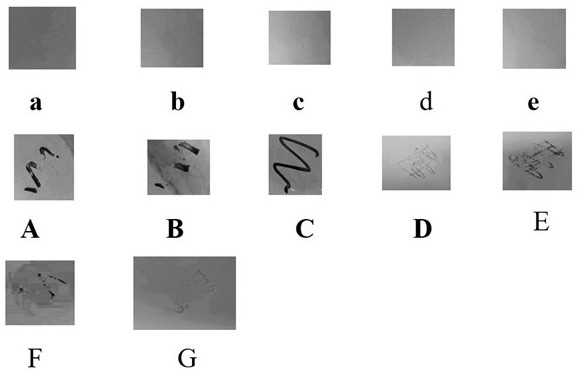

Image

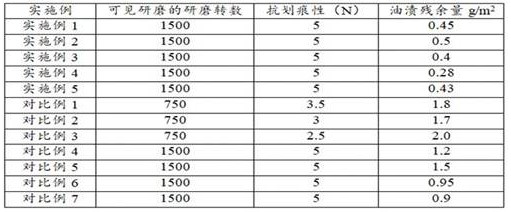

Examples

Embodiment 1

[0031] This example is an easy-to-clean ceramic tile provided by the present invention, including a glazed tile and a functional nano-layer coated on the surface of the glazed tile; in terms of mass percentage, the preparation raw material of the functional nano-layer includes sodium silicate 29 %, potassium silicate 14%, lithium silicate 5.5%, silicon phosphate 0.8%, sodium methyl silicate 1.4% and water 49.3%; the modulus of the sodium silicate is SiO 2 :Na 2 O=2.5, the modulus of the potassium silicate is SiO 2 :K 2 O=2.8, the modulus of the lithium silicate SiO 2 : Li 2 O=4.

[0032] The preparation method of above-mentioned easy-to-clean ceramic tile, comprises the steps:

[0033] (1) Clean the surface of qualified glazed tiles with a detergent with a pH of 6 for the first time, and then use a plasma device with a power of 1500VA for the second cleaning;

[0034] (2) Configure the functional nano solution according to the formula, and evenly spin-coat the functional n...

Embodiment 2

[0037] This example is an easy-to-clean ceramic tile provided by the present invention, including a glazed tile and a functional nano-layer coated on the surface of the glazed tile; in terms of mass percentage, the preparation raw material of the functional nano-layer includes sodium silicate 29 %, potassium silicate 18%, lithium silicate 3.8%, silicon phosphate 1.5%, sodium methyl silicate 0.85% and water 46.85%; the modulus of the sodium silicate is SiO 2 :Na 2 O=3, the modulus of the potassium silicate is SiO 2 :K 2 O=3, the modulus of the lithium silicate SiO 2 : Li 2 O=4.5.

[0038] The preparation method of above-mentioned easy-to-clean ceramic tile, comprises the steps:

[0039] (1) Clean the surface of qualified glazed tiles with a detergent with a pH of 7 for the first time, and then use a plasma device with a power of 1500VA for the second cleaning;

[0040] (2) Configure the functional nano-solution according to the formula, and evenly spin-coat the functional...

Embodiment 3

[0043] This example is an easy-to-clean ceramic tile provided by the present invention, including a glazed tile and a functional nano-layer coated on the surface of the glazed tile; in terms of mass percentage, the preparation raw material of the functional nano-layer includes sodium silicate 27 %, potassium silicate 13%, lithium silicate 10%, silicon phosphate 0.8%, sodium methyl silicate 1.3% and water 47.9%; the modulus of the sodium silicate is SiO 2 :Na 2 O=3.3, the modulus of the potassium silicate is SiO 2 :K 2 O=3.3, the modulus of the lithium silicate SiO 2 : Li 2 O=4.8.

[0044] The preparation method of above-mentioned easy-to-clean ceramic tile, comprises the steps:

[0045] (1) Clean the surface of qualified glazed tiles with a detergent with a pH of 6.5 for the first time, and then use a plasma device with a power of 1500VA for the second cleaning;

[0046] (2) Configure the functional nano-solution according to the formula, and evenly spin-coat the functio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com