Coke feeding device

A technology of coke and mounting frame, which is applied in the hoisting device, conveyor control device, packaging, etc., can solve the problems of affecting combustion efficiency, wasting energy, fixed feeding amount and feeding range cannot be better controlled, and achieve structural design It is novel and reasonable, extends the range of spreading materials, and is easy to promote and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

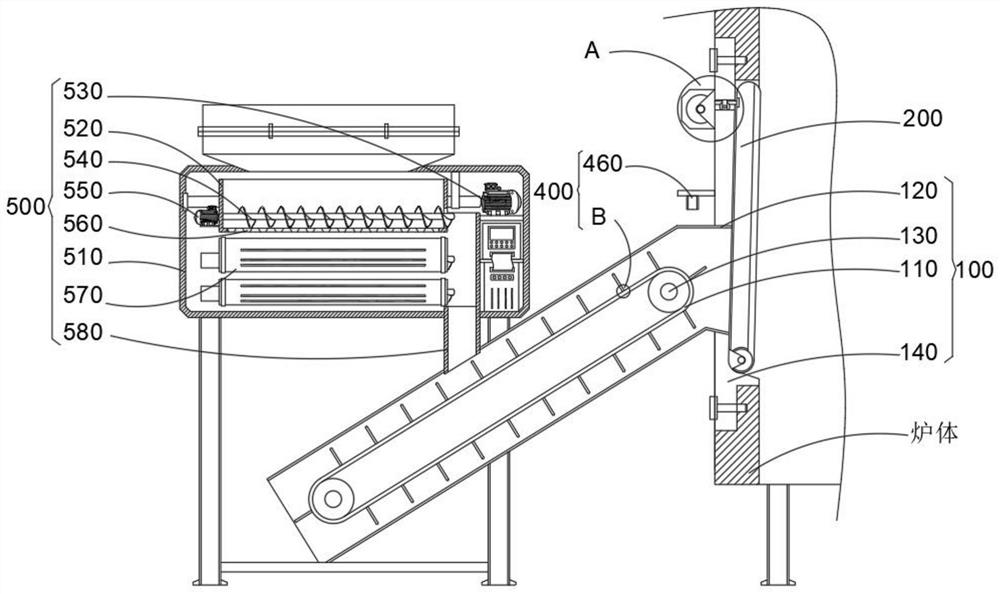

[0042] combine Figure 1-8As shown, the coke feeding device provided by the present invention includes: a feeding mechanism 100, a feeding mechanism 200, a lifting mechanism 300, a metering mechanism 400 and a screening mechanism 500, and the feeding mechanism 100 includes a conveyor belt 110 for transporting coke, The mounting frame 120 for the positioning and installation of the conveyor belt 110, the driver 130 installed on the mounting frame 120 and driving the conveyor belt 110 to rotate, and the mounting plate 140 connecting the mounting frame 120 and the operating furnace body, the mounting frame 120 is a U-shaped material with an inclined front facing upward Groove structure, the inner walls of the conveyor belt 110 and the partition plate 420 are close to the inside of the installation frame 120 to avoid spilling of coke, and the driver 130 is horizontally installed on the installation frame 120, and the conveyor belt 110 is driven to rotate by the driver 130. The driv...

Embodiment 2

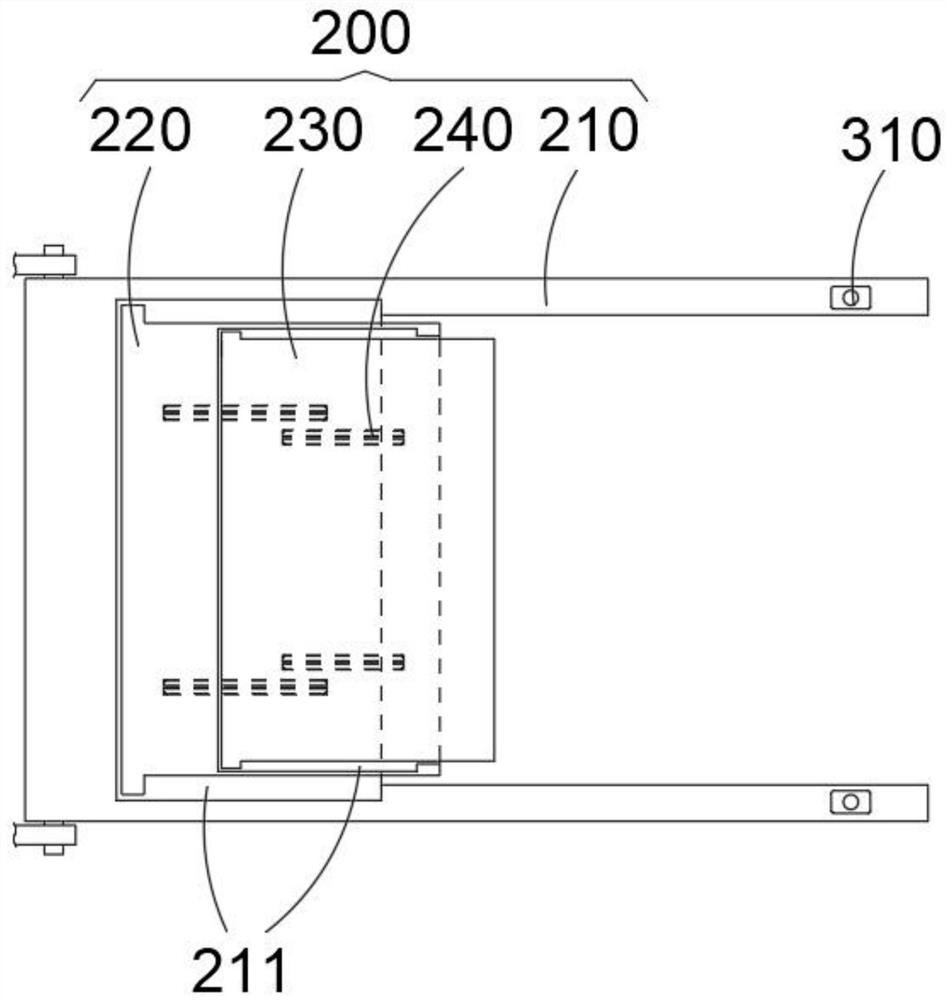

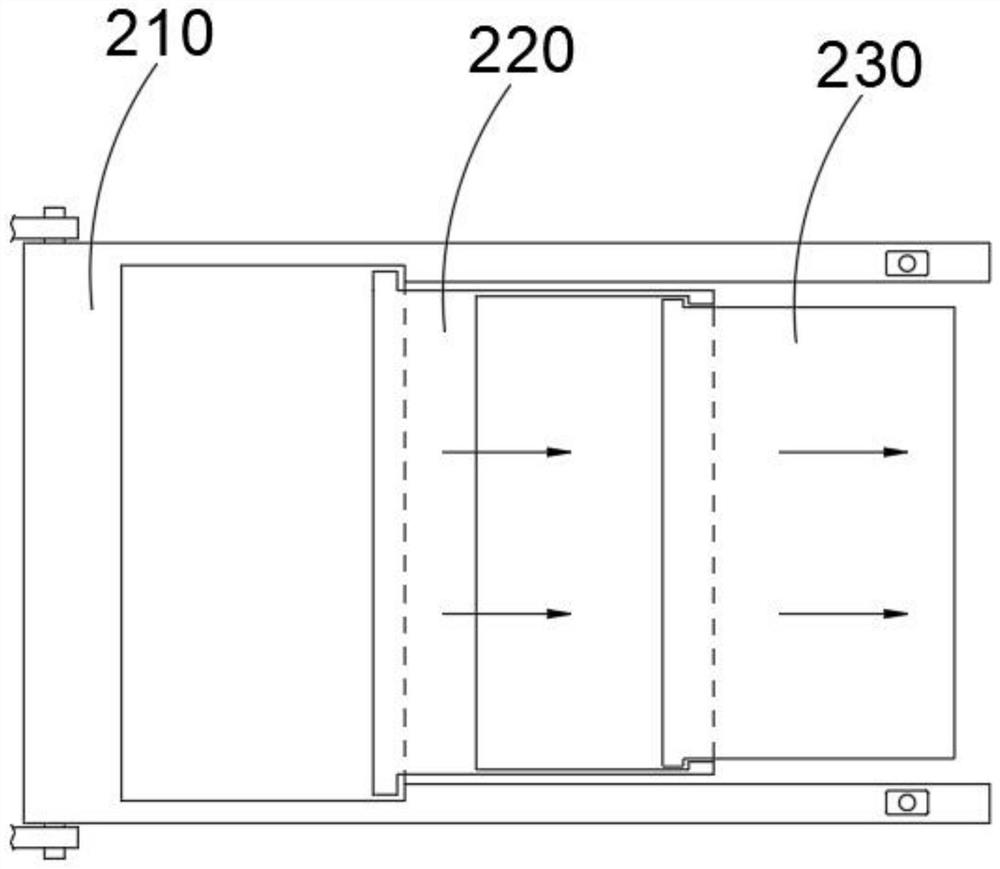

[0052] combine Figure 2-4 As shown, on the basis of Embodiment 1, the connecting frame 210 is a U-shaped structure, and the side of the connecting frame 210 is provided with a baffle to prevent coke from scattering, and the U-shaped structure connecting frame 210 can cooperate with the baffle to prevent coke from feeding The sides of the mechanism 200 are scattered, and at the same time, a hollow area is provided for the extension of the extension plate 1 220 and the extension plate 2 230, and the cables 310 are connected to the two ends of the U-shaped structure. Of course, the connecting frame 210 can also be set in the shape of a square structure, only the cable 310 needs to be connected to the middle of the movable end of the connecting frame 210, thereby improving the reliability of the device.

[0053] On the other hand, the bottoms of the connecting frame 210, the extension board 1 220 and the extension board 2 230 are all equipped with a fireproof board 212, which is ...

Embodiment 3

[0056] combine figure 1As shown, in the above embodiment, the screening box 570 is provided with two groups, and the screening box 570 includes another group of screening buckets 520, screw rods 540, motor two 550 and discharge holes 560, located below the screening buckets 520 The screening box 570 is provided with the same loading structure as the screening bucket 520, as well as the screw rod 540, the second motor 550 and the discharge hole 560, which have the functions of discharging and screening, while the other one located below the above screening box 570 The screening box 570 only includes a screening bucket 520, a screw rod 540 and a motor 2 550. It does not need a discharge hole 560 and then discharges downwards for storage, and the diameter of the discharge hole 560 in the screening box 570 is much smaller than that of the screening bucket. The aperture of discharge hole 560 in 520 is for coke chips to pass through. Of course, more screening boxes 570 can be instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com