Golf club head grinding method

A golf club head and grinding method technology, which can be applied to grinding devices, grinding machine tools, grinding machines, etc., can solve the problems of time-consuming and labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the above-mentioned and other purposes, features and advantages of the present invention more obvious and understandable, the following is based on preferred embodiments of the present invention, and is described in detail as follows in conjunction with the accompanying drawings:

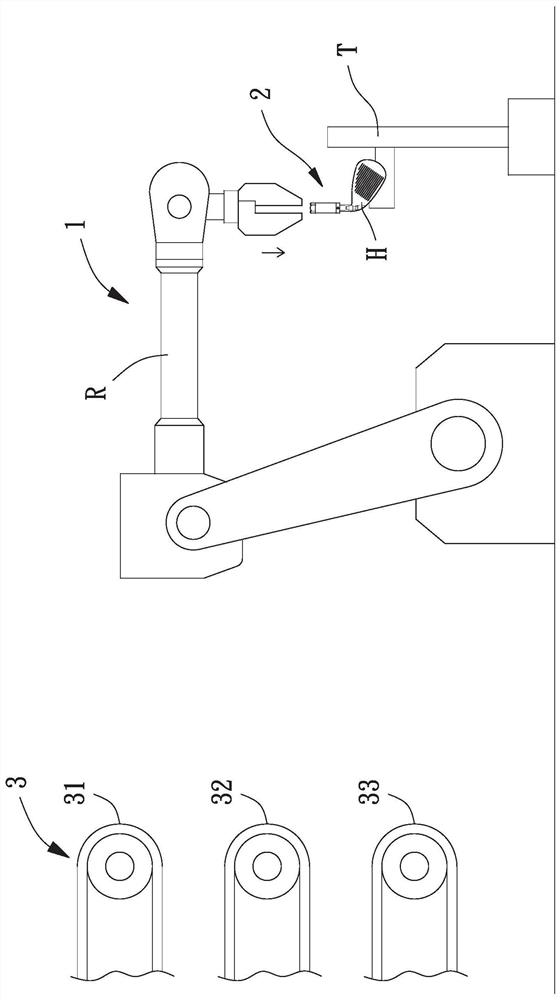

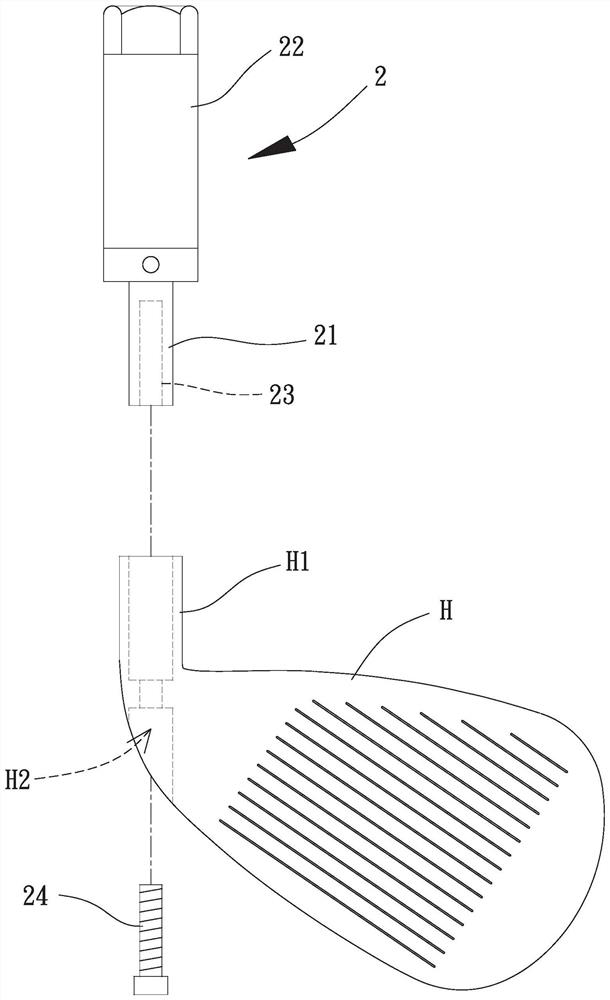

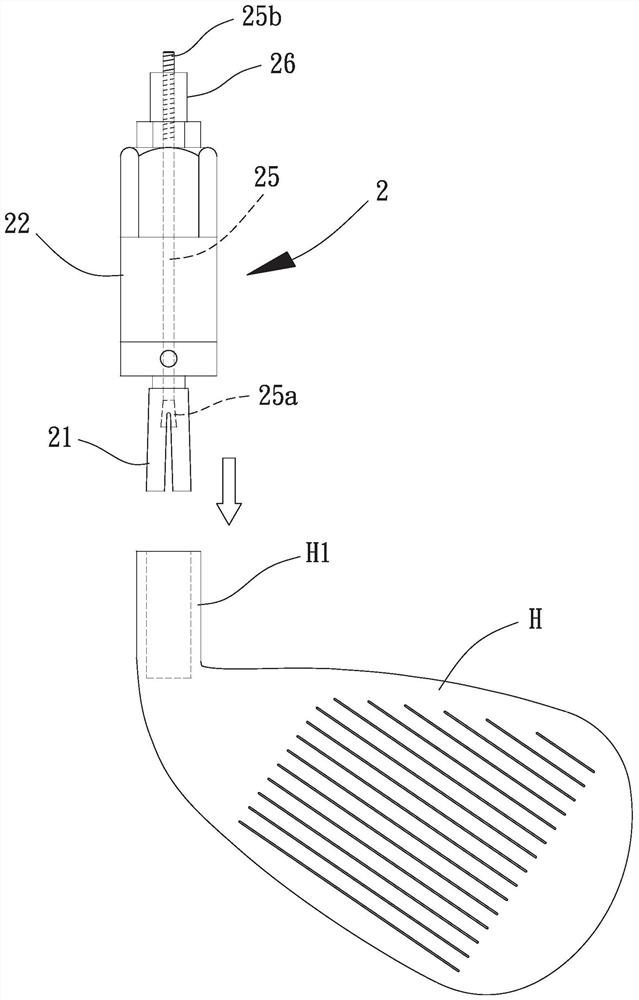

[0041] Please refer to figure 1 As shown, the golf club head grinding method according to an embodiment of the present invention may include: using a clamping device 1 to clamp a positioning member 2 to send a golf club head semi-finished product H to a surface treatment device 3, so as to The surface treatment device 3 grinds the semi-finished golf club head H at least twice; and polishes the semi-finished golf club head H.

[0042] Specifically, a plurality of the golf club head semi-finished products H can be placed on a club head placement part T in advance, and the clamping device 1 can clamp a golf club head semi-finished product H from the ball head placement part T, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com