Pickering emulsion and preparation method thereof

An emulsion and raw material liquid technology, applied in the field of biomass materials and colloid chemistry, can solve the problems of short fruit preservation time and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A first aspect of the present invention provides a kind of preparation method of Pickering emulsion, comprises the following steps:

[0031] Mixing the chitosan-chlorogenic acid raw material solution with cinnamaldehyde essential oil to obtain a mixed solution;

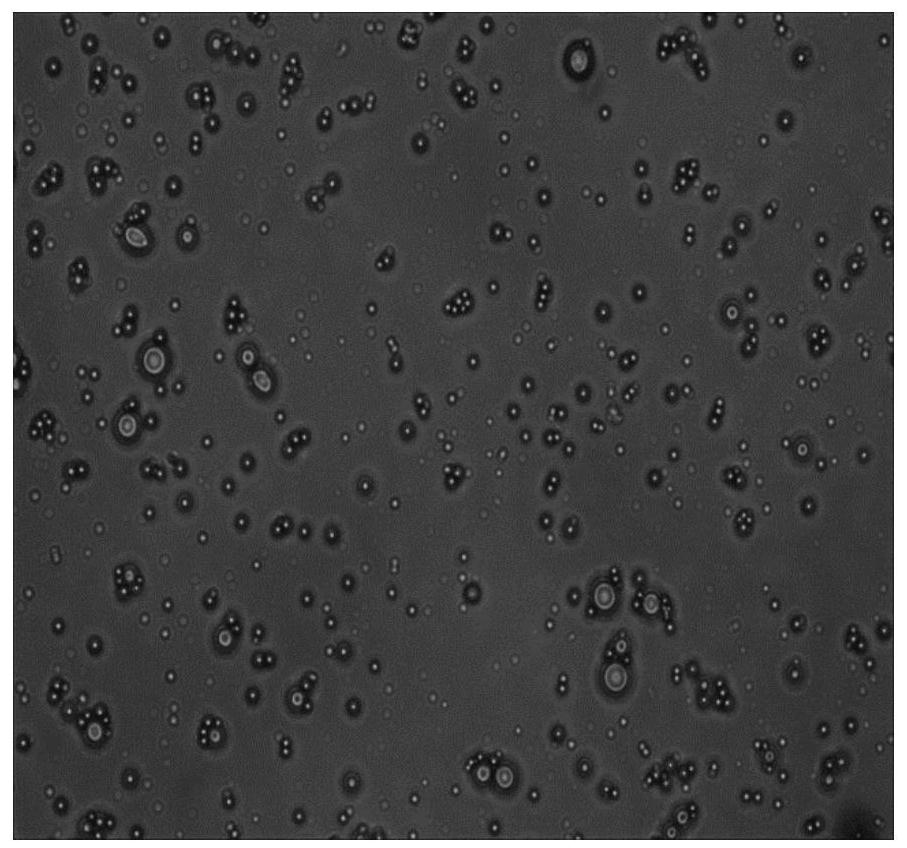

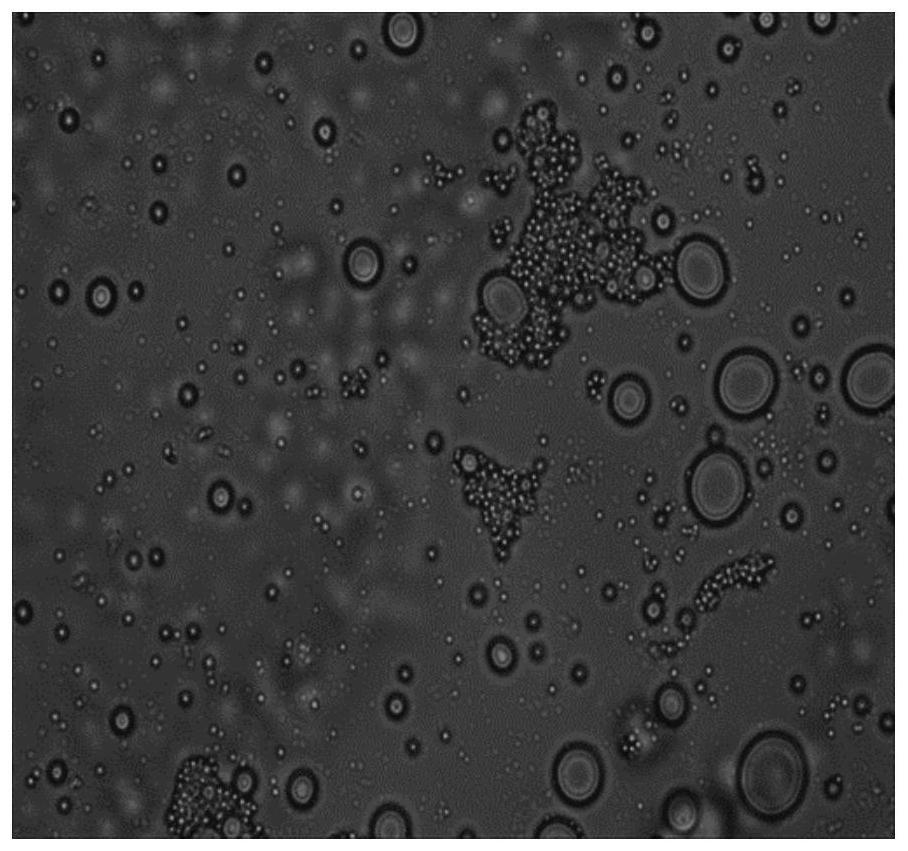

[0032] The mixed solution is post-treated to obtain a Pickering emulsion; post-processing includes shearing treatment and homogenization treatment in turn;

[0033] The chitosan-chlorogenic acid raw material solution at least includes chitosan-chlorogenic acid nanoparticles.

[0034] In the present invention, the chitosan-chlorogenic acid raw material solution comprising at least chitosan-chlorogenic acid nanoparticles is mixed with cinnamaldehyde to obtain a mixed solution, and the mixed solution contains chitosan-chlorogenic acid nanoparticles and cinnamaldehyde essential oil, followed by post-treatment of the mixed solution including shear treatment and homogenization treatment, so that the chitosan-chlorog...

Embodiment 1

[0080] The Pickering emulsion of the present embodiment is prepared by the method comprising the following steps;

[0081] 1) prepare chitosan acid solution

[0082] 0.8g chitosan is dissolved in the acetic acid solution that molar concentration is 0.3mol / L, after fully dissolving, adjust solution pH to 4.8, obtain chitosan acidic solution;

[0083] 2) Prepare chitosan-chlorogenic acid solution

[0084] Add 0.4g of chlorogenic acid to 100mL of chitosan acidic solution obtained in step 1), fully dissolve to obtain chitosan-chlorogenic acid solution;

[0085] 3) Prepare TPP aqueous solution

[0086]Dissolve 0.05g of sodium tripolyphosphate (TPP) in distilled water, and constant volume in a 50mL volumetric flask to obtain a TPP aqueous solution;

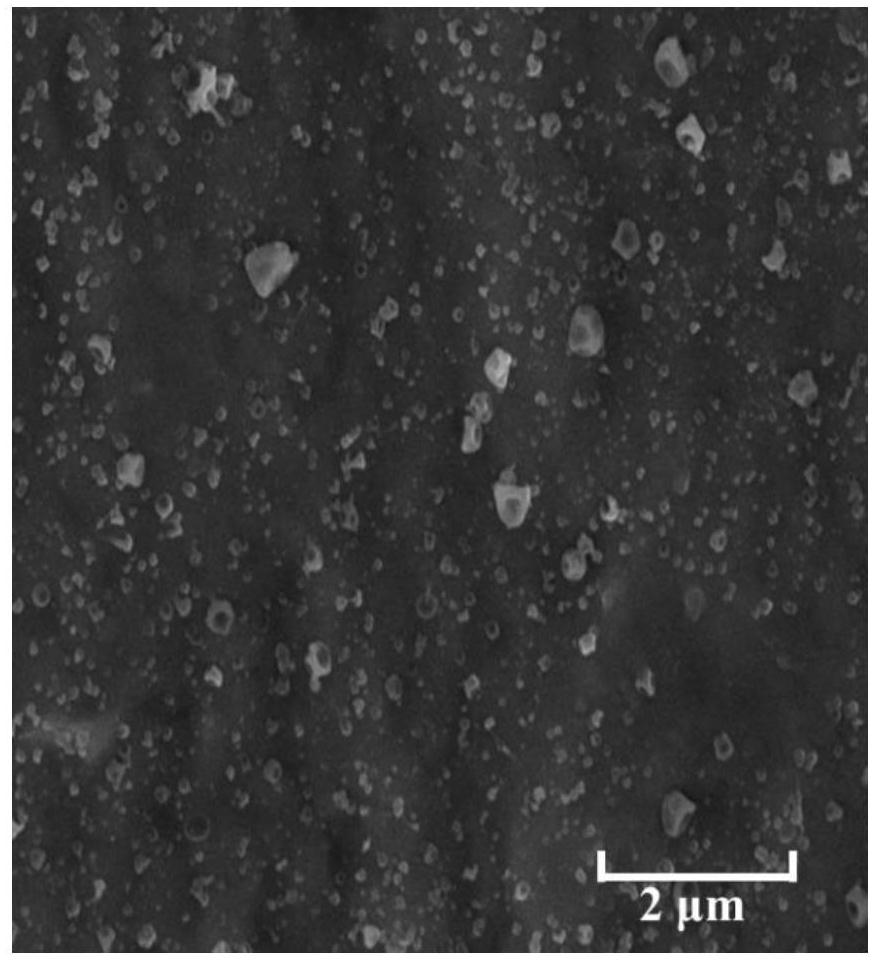

[0087] 4) Preparation of chitosan-chlorogenic acid nanoparticles

[0088] Add 100mL of chitosan-chlorogenic acid solution dropwise into the TPP aqueous solution, stir for 2h, centrifuge at 4000r / min for 10min, retain the precipitate...

Embodiment 2

[0097] The Pickering emulsion of the present embodiment is prepared by the method comprising the following steps;

[0098] 1) prepare chitosan acid solution

[0099] 0.8g chitosan is dissolved in the acetic acid solution that molar concentration is 0.3mol / L, after fully dissolving, adjust solution pH to 4.8, obtain chitosan acidic solution;

[0100] 2) Prepare chitosan-chlorogenic acid solution

[0101] Add 0.4g of chlorogenic acid to 100mL of chitosan acidic solution obtained in step 1), fully dissolve to obtain chitosan-chlorogenic acid solution;

[0102] 3) Prepare TPP aqueous solution

[0103] Dissolve 0.05g of sodium tripolyphosphate (TPP) in distilled water, and constant volume in a 50mL volumetric flask to obtain a TPP aqueous solution;

[0104] 4) Preparation of chitosan-chlorogenic acid nanoparticles

[0105] Add 100mL of chitosan-chlorogenic acid solution dropwise into the TPP aqueous solution, stir for 2h, centrifuge at 4000r / min for 10min, retain the precipitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| embedding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com