Novel water cooling structure of water pump motor

A water pump motor and water cooling technology, which is applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of high temperature failure of permanent magnets, magnetic attenuation of permanent magnets, damage of water pumps, etc., to avoid high temperature failure or damage, ensure work efficiency, Ease of maintenance and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

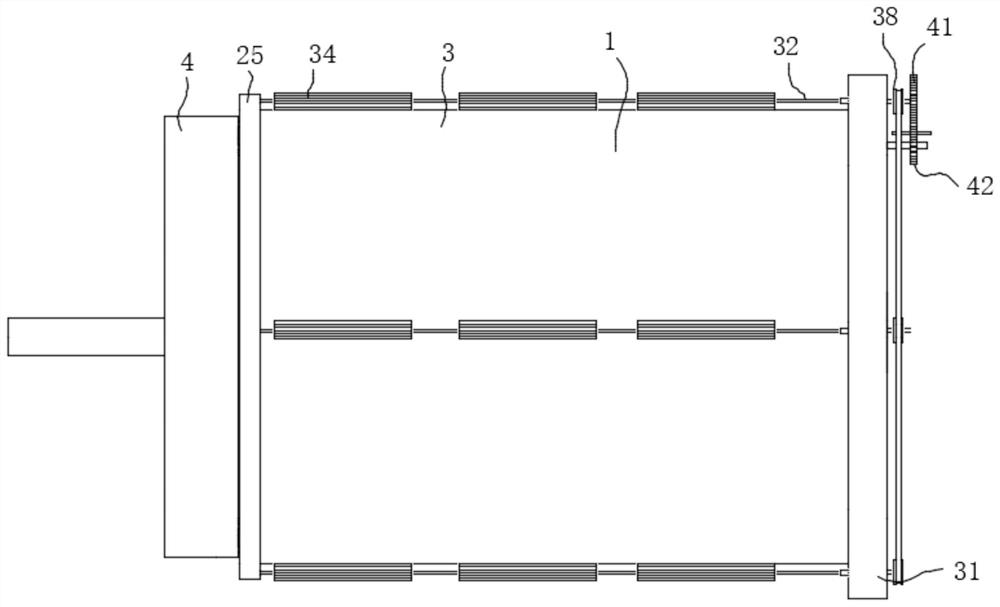

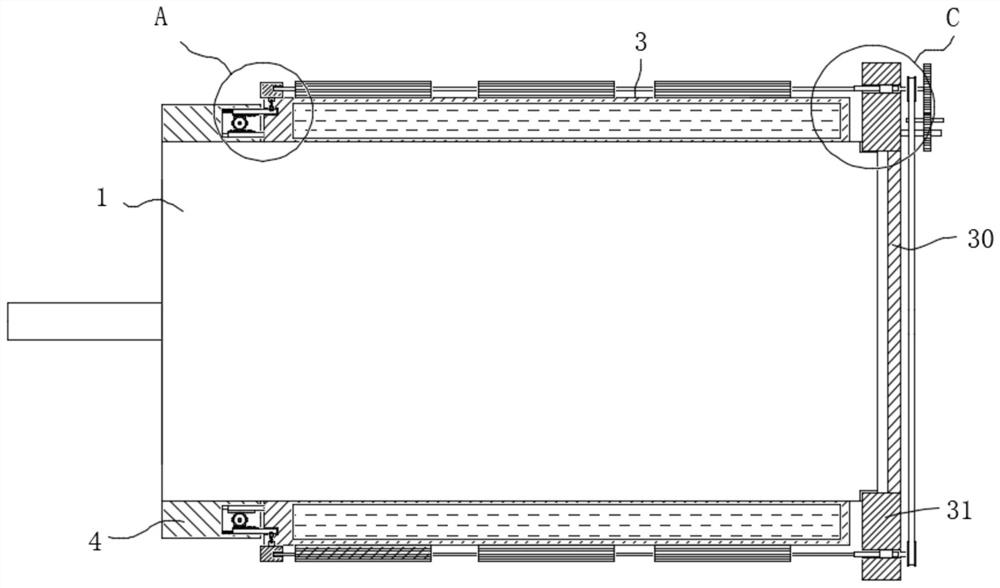

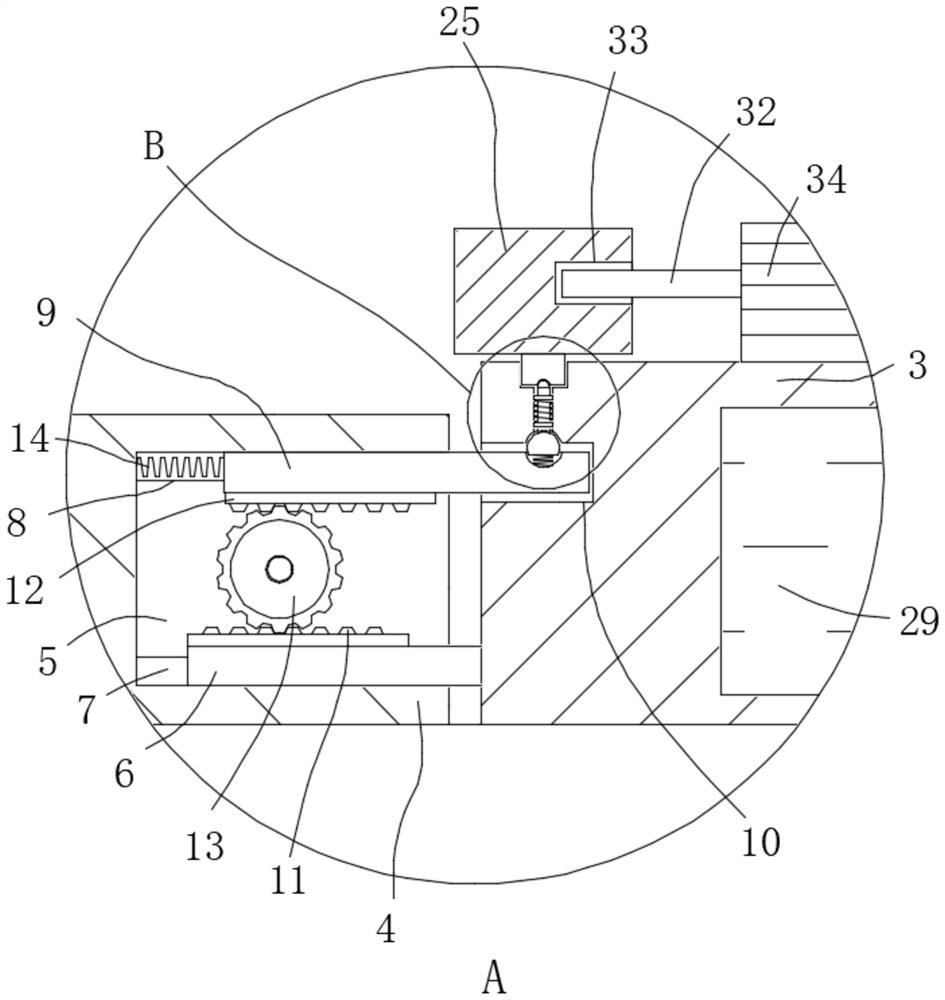

[0030] Please combine Figures 1 to 7 The new water pump motor water-cooled structure includes a housing 1 and a heat exchange barrel 3 that is attached to the outer peripheral side of the casing 1, and the casing 1 is a housing of the water pump motor. The heat exchange cylinder 3 is adapted to the casing 1, so that the inner casing wall of the heat exchange tube 3 is completely bonded to the outer wall of the casing 1, and the amount of heat near the stator can be well conducted when the motor is operated. The inner surface of the cylinder wall of the heat exchange tube 3 has a flow path cavity 29 surrounding the casing 1, and the flow diaphragm 29 extends in the axial direction of the casing 1, and is surrounded by the outer side of the casing 1, so that the refrigerant is in the flow channel cavity 29 The inner average can be flowable to heat transfer to each position on the outer peripheral side of the casing 1. The flow path cavity 29 is housed in a refrigerant of the casing ...

Embodiment 2

[0048] This Example 2 is a modified scheme of Example 1. Specifically, the side wall of the heat exchange cylinder 3 is switched from the respective side wall, and the inlet of the inner portion of the interior of the flow path cavity 29 is changed. The water bar is provided with a water outlet (not shown) on the side wall of the other end of the hot tube 3. Cooling water having pressure is conveyed through the flow of the heat exchange tube 3 through the inlet.

[0049] Valves are mounted on the inlet and outlet ports in this embodiment. When the water pump is used to transport water, the inlet of the flow channel chamber 29 can be connected to the water pump of the water pump by a conduit, and the effluent of the flow channel cavity 29 is connected to the water pump of the water pump through the catheter, so that in order to flow Cooling water having a certain pressure is delivered within the road cavity 29.

[0050] When the cooling water having the pressure is flowing into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com