Cable laying construction method

A construction method and cable laying technology, applied in the directions of cable laying equipment, cable installation, optical fiber/cable installation, etc., can solve the problems of reduced cable current carrying capacity, increased energy consumption of cable sheath, increased cable temperature, etc. Number of wells, reduction of laying depth, effect of reducing negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

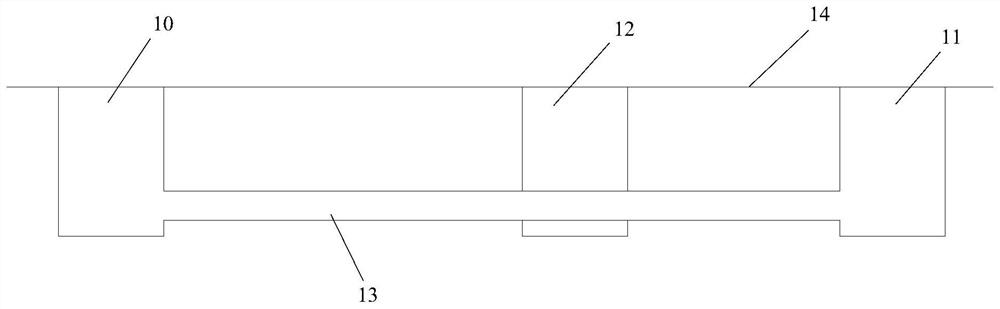

[0050] like Figures 1 to 3 Shown, cable laying construction method of the present invention comprises the following steps:

[0051]The first step is to set the pipeline 13 for laying cables;

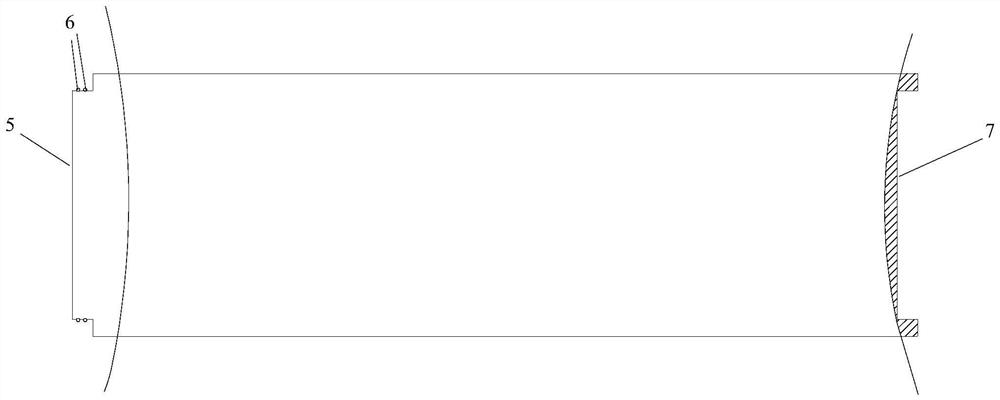

[0052] In the second step, a cable jacking shaft 10 and a cable receiving shaft 11 are set up on the ground 14, and a pipeline jacking device is used in the underground to carry out the jacking operation of the pipeline from the cable jacking shaft 10 to the cable receiving shaft 11 to lay the pipeline; specifically Said, the laying depth of the pipeline 13 is 4-5 meters, the pipeline jacking device comprises a thrust device and a tool pipe, the pipeline 13 is offset against the tool pipe, and the thrust device is used to push the pipeline 13, and the tool pipe moves toward the soil layer under the thrust of the thrust device. Inner excavation, the excavated soil is discharged to realize the jacking and laying of the pipeline 13 to the soil layer; finally, the tool pipe is hoisted from...

Embodiment 2

[0069] The difference between this embodiment and Embodiment 1 is that the magnetic isolation structure refers to: each middle tube is a non-closed structure with an opening, the opening faces the gap, and the gap is provided with a non-magnetic material, wherein the non-magnetic material is stainless steel , copper and aluminum etc.

[0070] Other structures of this embodiment are consistent with Embodiment 1.

Embodiment 3

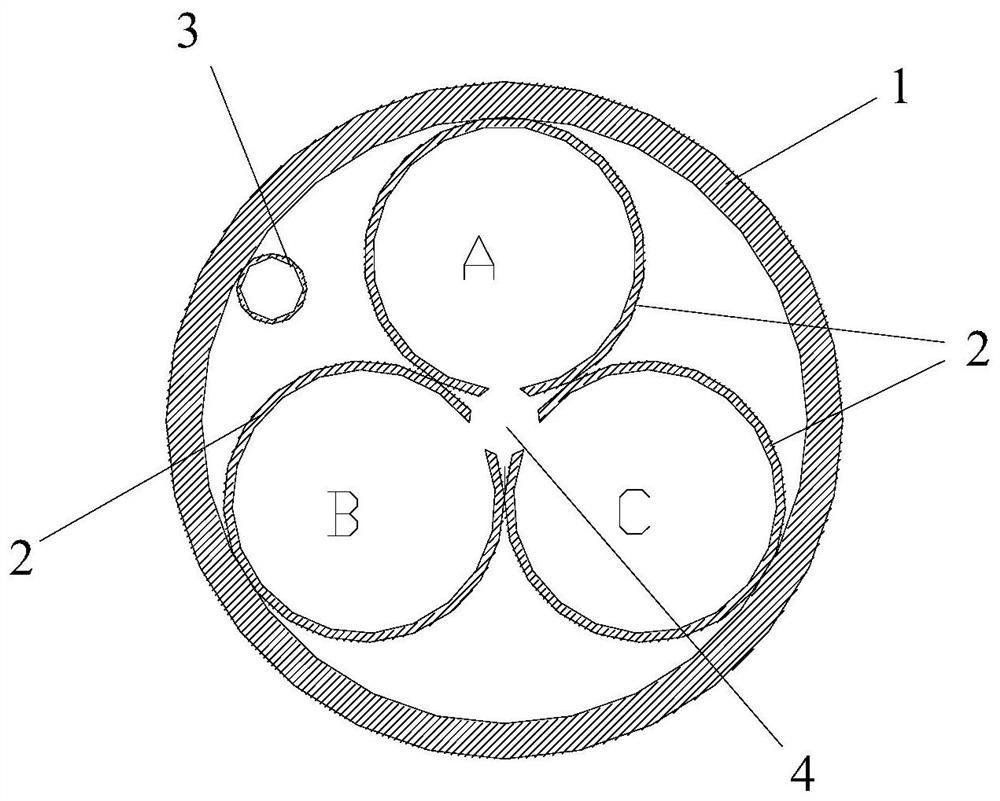

[0072] This embodiment differs from Embodiment 1 only in that: Figure 4 As shown, the pipe joints of this embodiment are pipe joints made of metal or reinforced concrete, and each pipe joint is prefabricated with three through holes 8 and a small through hole 9, and the three cables A, B and C of the same circuit respectively pass through the through holes 8 , and the communication optical cables pass through the small through holes 9 . Wherein, the three through-holes 8 are arranged to form a zigzag, so that the three cables passing through the three through-holes 8 are arranged in a zigzag.

[0073] In this embodiment, there are gaps 4 in the middle of the three through-holes 8 arranged in the shape of a character. The through-holes 8 are provided with a magnetic isolation structure for making the single-core cable in a non-closed magnetic circuit. The magnetic isolation structure refers to: each through-hole 8 It is a non-closed structure with an opening, the opening face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com