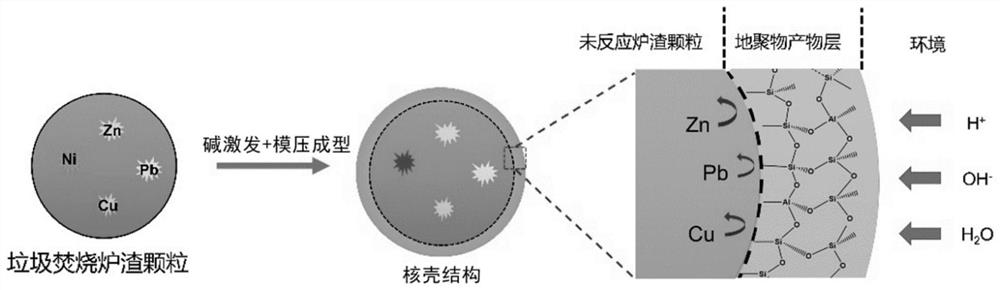

Cement-free waste incineration slag-based baking-free brick and preparation method thereof

A technology of waste incineration slag and burn-free bricks, which is applied in the field of resource utilization of waste incineration slag, and can solve the problems of poor operability, complicated operation, and low curing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

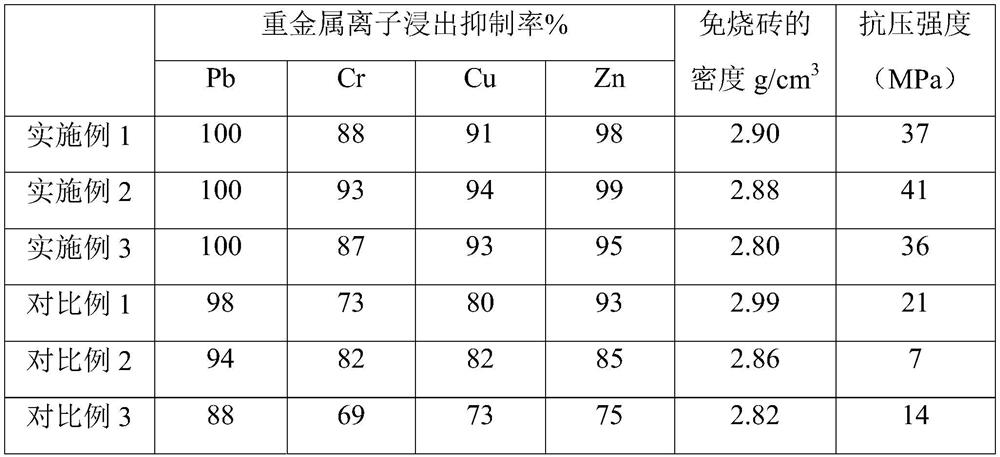

Embodiment 1

[0035] An unburned brick, comprising the following components in parts by mass:

[0036] 6 parts of waste incineration slag, 2 parts of metakaolin and 3 parts of alkali activator;

[0037] The waste incineration slag contains by mass percentage: 45.3% CaO, 15% SiO 2 , 6.8% Fe 2 o 3 and 3.1% Al 2 o 3 ; The heavy metal elements contained in the waste incineration slag are Cu (1586ppm), Zn (8460ppm), Pb (1450ppm) and Cr (950ppm);

[0038] The alkali activator includes, by mass percentage, 30% of liquid sodium silicate, 6% of NaOH and the rest of water; wherein, the modulus of the liquid sodium silicate is 3.1.

[0039] The preparation method of above-mentioned burn-free brick is:

[0040] a. Grinding the waste incinerator slag to a particle size of ≤75 μm and mixing it evenly with the above-mentioned metakaolin and alkali activator to obtain a semi-dry material;

[0041] b. Add the semi-dry material into the mold, hold the pressure at 10KN for 35s, and obtain the forming t...

Embodiment 2

[0044] An unburned brick, comprising the following components in parts by mass:

[0045] 7 parts of waste incineration slag, 3 parts of rice husk ash and 4 parts of alkali activator;

[0046] The waste incineration slag contains by mass percentage: 47.3% CaO, 16.6% SiO 2 , 7.4% Fe 2 o 3 and 4.2% Al 2 o 3 ; The heavy metal elements contained in the waste incineration slag are Cu (1588ppm), Zn (8544ppm), Pb (1670ppm) and Cr (1010ppm);

[0047] The alkali activator includes, by mass percentage, 32% of liquid sodium silicate, 6.5% of NaOH and the rest of water; wherein, the modulus of the liquid sodium silicate is 3.2.

[0048]The preparation method of above-mentioned burn-free brick is:

[0049] a. Grinding the waste incinerator slag to a particle size of ≤75 μm and mixing it evenly with the above-mentioned rice husk ash and alkali activator to obtain a semi-dry material;

[0050] b. Add the semi-dry material into the mould, hold the pressure at 12KN for 30s, and obtain th...

Embodiment 3

[0053] An unburned brick, comprising the following components in parts by mass:

[0054] 8 parts of garbage incineration slag, 4 parts of volcanic ash and 5 parts of alkali activator;

[0055] The waste incineration slag contains by mass percentage: 49.9% CaO, 20% SiO 2 , 8% Fe 2 o 3 and 4.8% Al 2 o 3 ; The heavy metal elements contained in the waste incineration slag are Cu (1662ppm), Zn (8820ppm), Pb (1433ppm) and Cr (960ppm);

[0056] The base activator includes, by mass percentage: 34% liquid sodium silicate, 7% NaOH and the rest of water; wherein, the modulus of the liquid sodium silicate is 3.3.

[0057] The preparation method of above-mentioned burn-free brick is:

[0058] a. Grinding the waste incinerator slag to a particle size of ≤75 μm and mixing it evenly with the above-mentioned pozzolan and alkali activator to obtain a semi-dry material;

[0059] b. Add the semi-dry material into the mould, hold the pressure at 15KN for 25s, and obtain the forming test pie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com