Negative pole piece, electrochemical device containing the negative pole piece and electronic device

A technology of negative electrode sheet and negative electrode material layer, which is applied in the field of electrochemistry, can solve problems such as shedding, affecting the electrochemical performance of lithium-ion secondary batteries, and negative electrode material rupture, so as to alleviate lithium intercalation expansion, improve cycle performance, and improve expansion. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

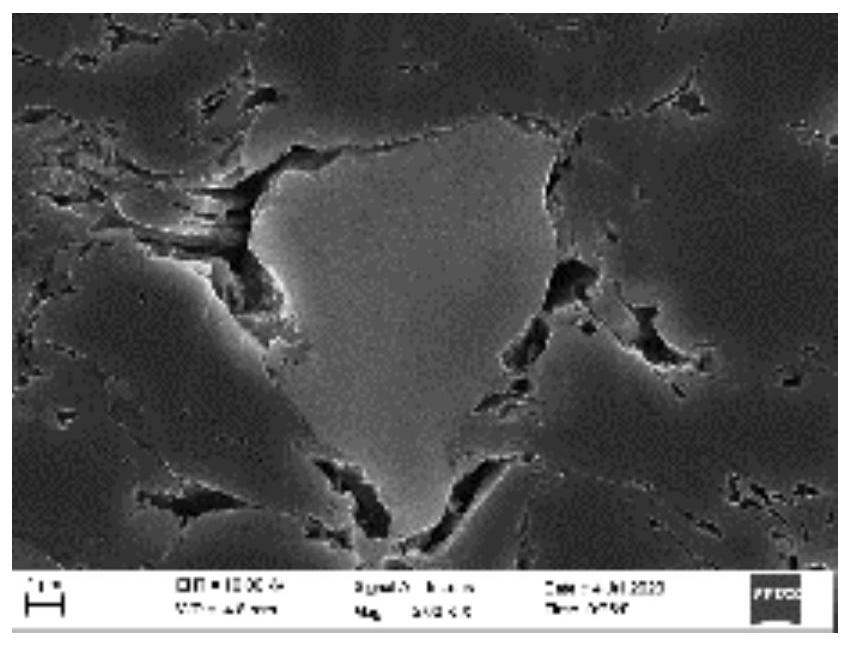

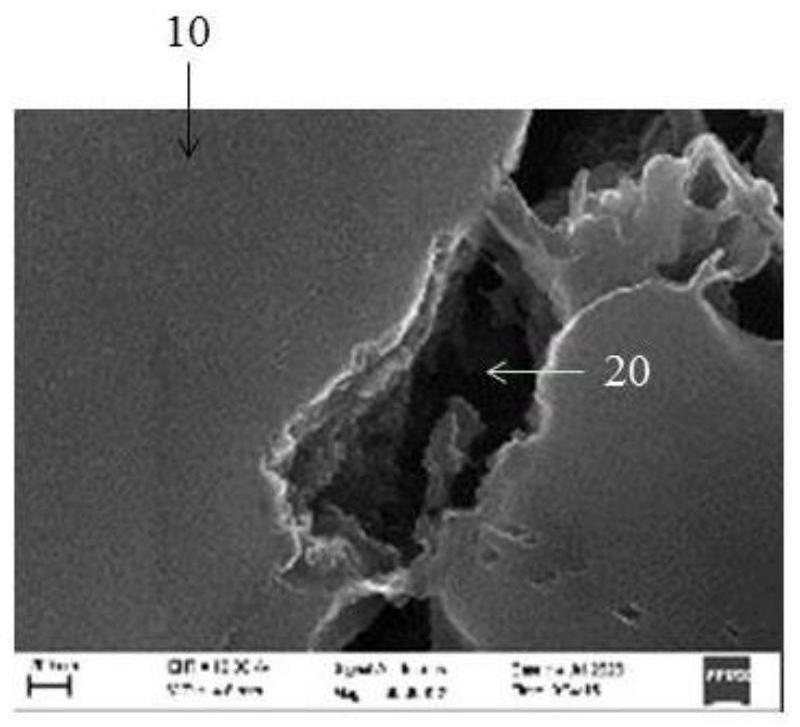

Image

Examples

Embodiment 1

[0086]

[0087] Put a porous carbon material with a porosity of 38% in a closed silicon-containing gas reactor, heat it to 500°C and keep it warm for 4 hours, and after cooling, sieve and demagnetize to obtain the porosity α of silicon-based particles 1 It is 16% silicon-based particles, wherein the carbon content of the silicon-based particles is 60wt%, and the silicon content B in the silicon-based particles is 40wt%.

[0088]

[0089] Mix the negative electrode active material prepared above, graphite particles and nano conductive carbon black according to the mass ratio of 30:66.5:3.5 to obtain the first mixture; add the first mixture and the binder PAA according to the mass ratio of 95:5 to deionized In water, it is prepared into a slurry with a solid content of 45%, and stirred evenly to obtain the first mixed slurry; the first mixed slurry is uniformly coated on one surface of a negative electrode current collector copper foil with a thickness of 8 μm, and dried in t...

Embodiment 2

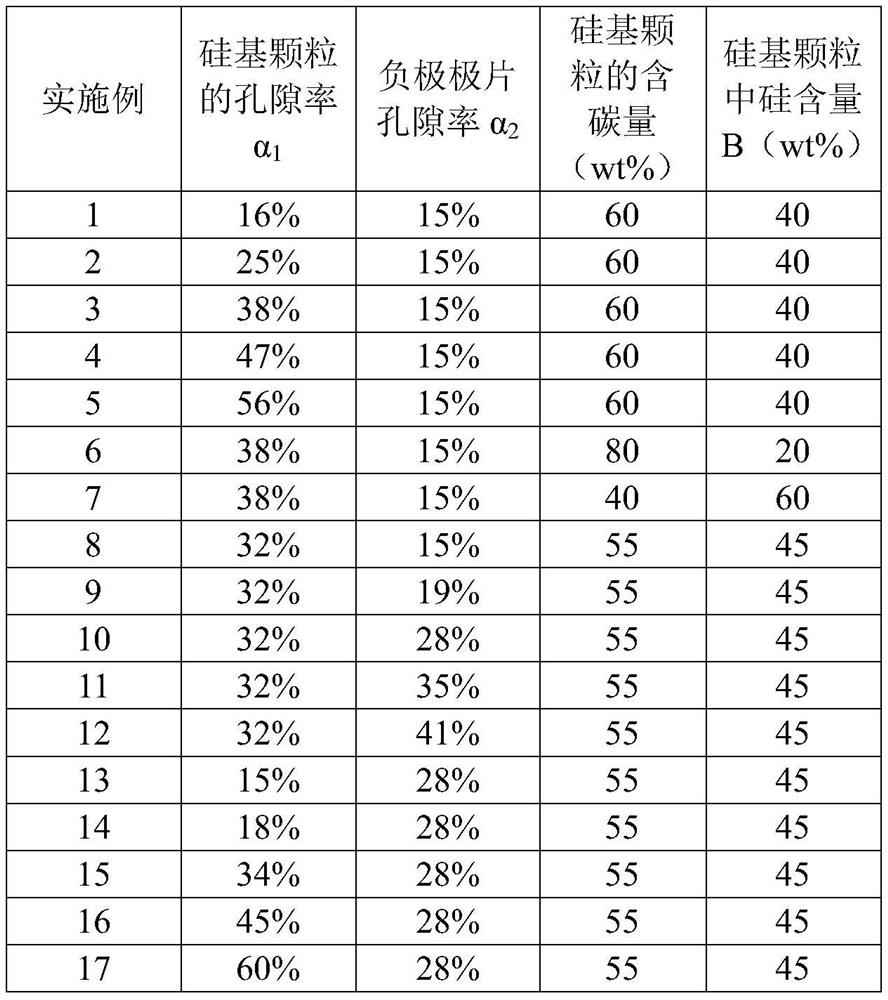

[0099] Example 2, Example 3, Example 4, Example 5, Example 6, Example 7, Example 8, Example 9, Example 10, Example 11, Example 12, Example 13, Example 14. In Example 15, Example 16 and Example 17, , , , , and are the same as in Example 1, and the changes of relevant preparation parameters are shown in Table 1:

[0100] Table 1

[0101]

Embodiment 18

[0103]

[0104] 1) Put a porous carbon material with a porosity of 38% in a closed silicon-containing gas reactor, heat it to 500°C and keep it warm for 4 hours, and after cooling, sieve and demagnetize to obtain the porosity of silicon-based particles alpha 1 It is 16% silicon-based particles, wherein the carbon content of the silicon-based particles is 60wt%, and the silicon content B in the silicon-based particles is 40wt%.

[0105] 2) Add the silicon-based particles obtained in 1) to single-walled carbon nanotubes (SCNT) containing carboxymethylcellulose sodium (CMC-Na) dispersant and disperse for 2 hours until a uniform mixed solution is formed, and spray dry to obtain powder, crushed, and sieved with 400 meshes to obtain the negative electrode material, wherein the mass ratio of silicon-based particles: SCNT: sodium carboxymethylcellulose is 99.75:0.1:0.15.

[0106] , , , , are the same as in Example 2.

[0107] Example 19, Example 20, Example 21, Example 22, Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com