High-temperature-resistant lithium ion battery diaphragm as well as preparation method and application thereof

A lithium-ion battery and high-temperature-resistant technology, which is applied in the field of lithium-ion batteries, can solve the problems of difficulty in ensuring flame retardancy, poor coating of polyolefin separators, and peeling of coatings, and achieve good thermal stability and flame retardancy. Strong, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Another embodiment of the present invention also provides a method for preparing the above-mentioned high-temperature-resistant lithium-ion battery separator, including the following steps:

[0051] The polymer is dissolved in an organic solvent, uniformly coated on the surface of the substrate, and dried to obtain a high-temperature resistant lithium-ion battery separator.

[0052] The preparation method of the above-mentioned high-temperature-resistant lithium-ion battery diaphragm has simple operation and low cost, and can realize large-scale production, and the prepared high-temperature-resistant lithium-ion battery diaphragm has good stability and flame-retardant performance.

[0053] In some of the embodiments, the quaternized polymethyl vinyl ether-maleic anhydride (qPMVMMA) is prepared according to steps S11-S16. Concrete synthetic route is as follows:

[0054]

[0055] Step S11: dissolving polymethyl vinyl ether-maleic anhydride in toluene;

[0056] Step S...

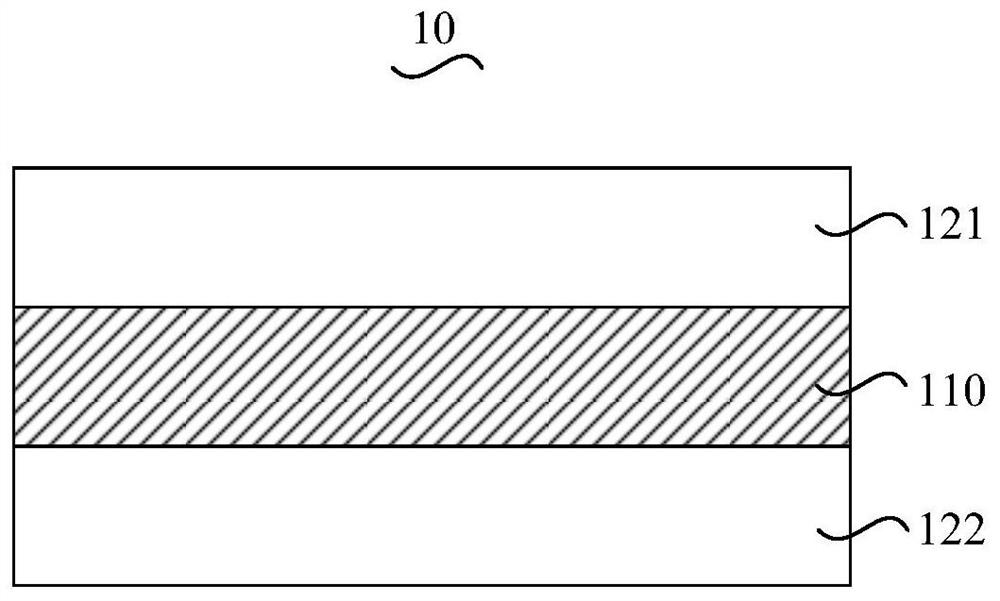

Embodiment 1

[0070] Dissolve quaternized polymethylvinyl ether-maleic anhydride (qPMVMMA) in isopropanol solution, and evenly coat it on the PP substrate after completely dissolving, and dry to obtain the high-temperature-resistant lithium-ion battery separator of Example 1. Among them, the thickness of the flame retardant coating is 3 μm, and the thickness of the PP base layer is 30 μm.

Embodiment 2

[0072] Dissolve quaternized polymethylvinyl ether-maleic anhydride (qPMVMMA) in isopropanol solution, and evenly coat it on the PP substrate after completely dissolving, and dry to obtain the high-temperature-resistant lithium-ion battery separator of Example 2. Among them, the thickness of the flame retardant coating is 5 μm, and the thickness of the PP base layer is 30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com