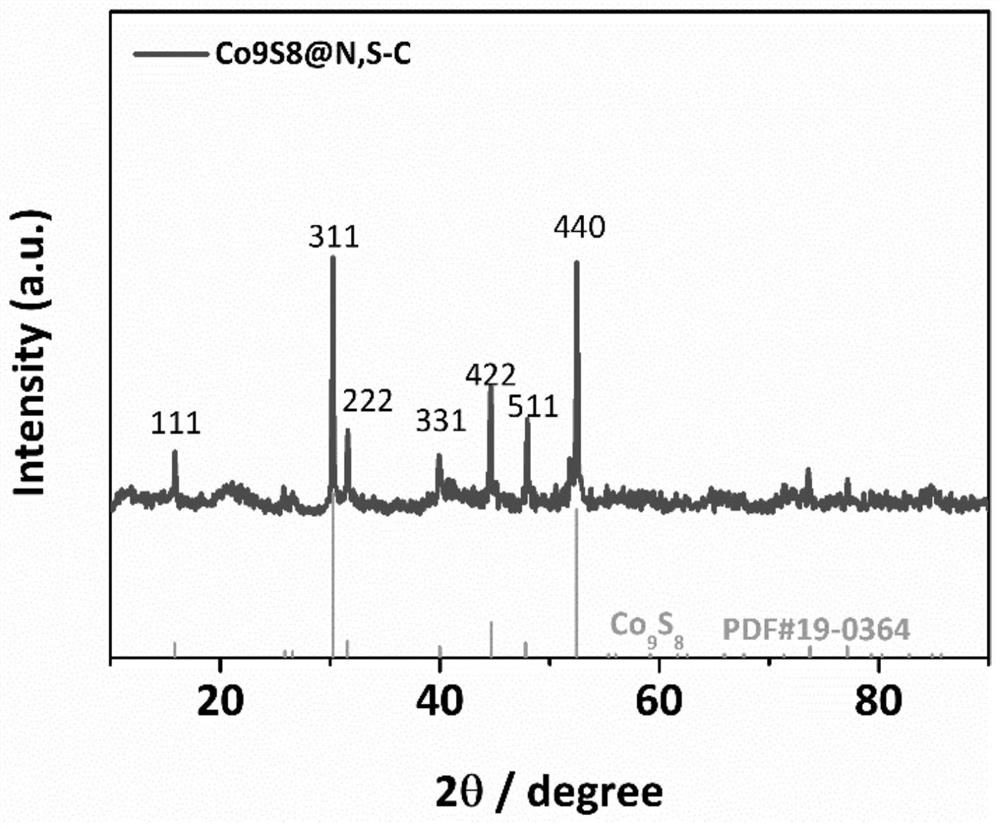

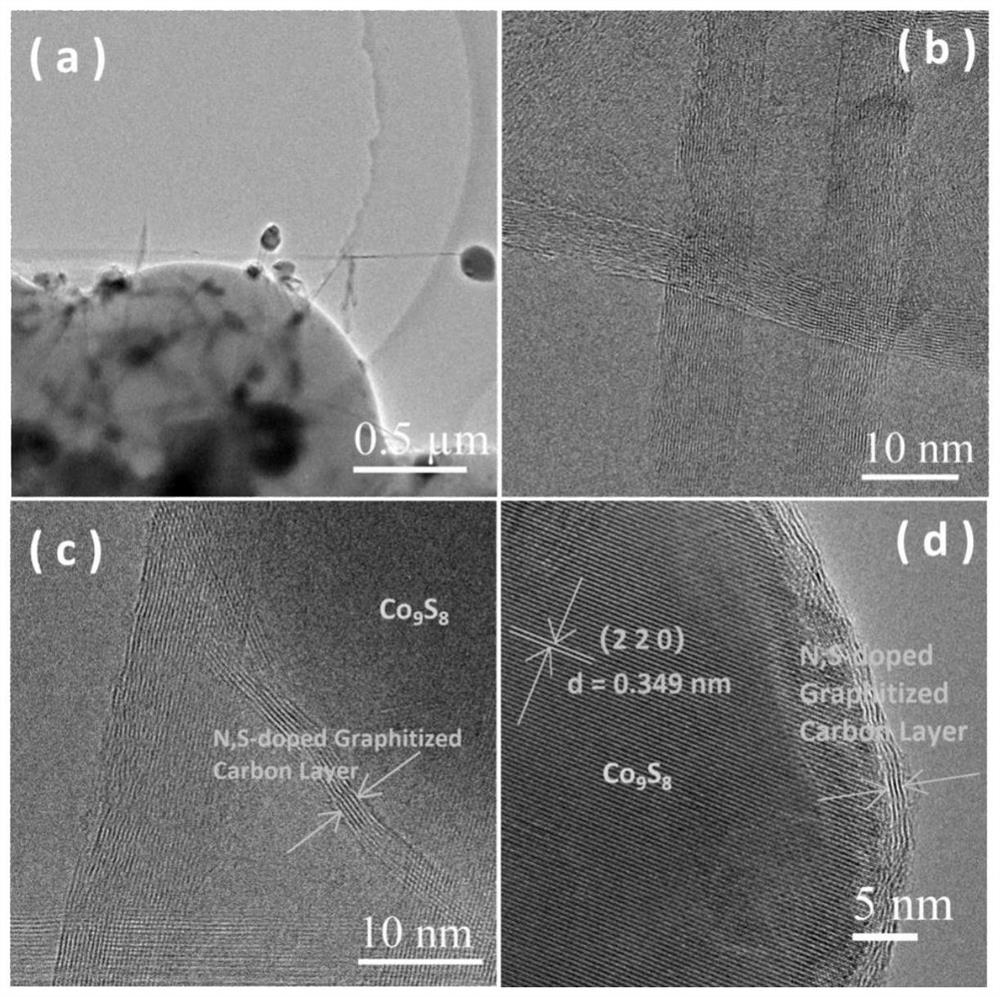

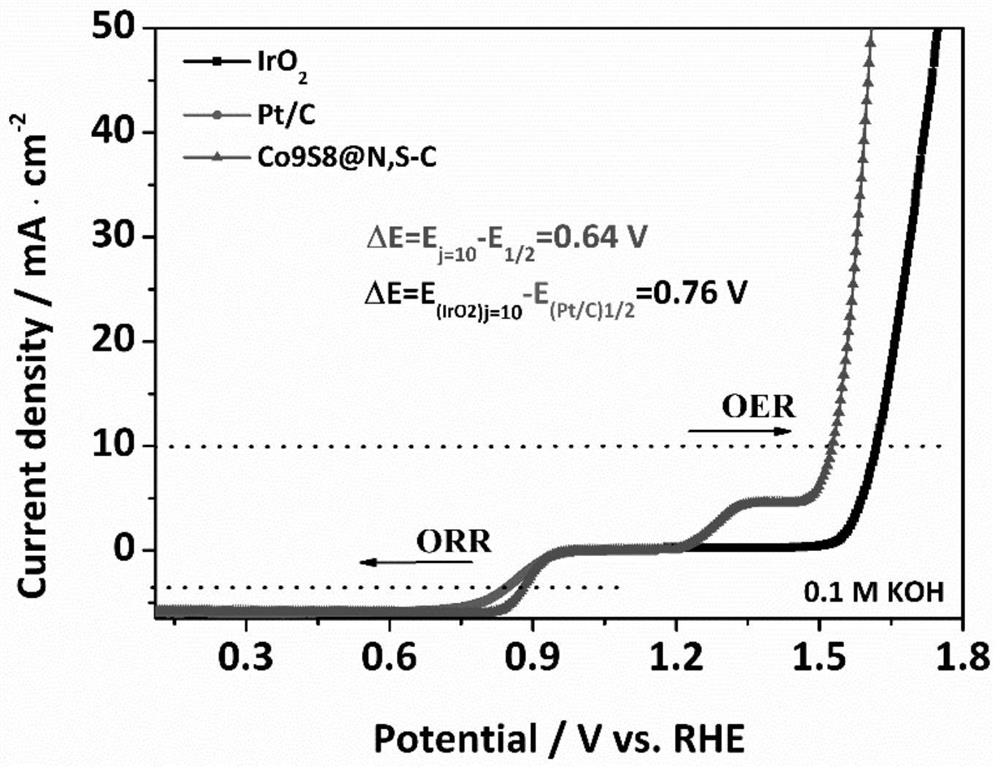

Preparation method of nitrogen-sulfur co-doped carbon-coated transition metal nano sulfide electrochemical oxygen catalyst

A nitrogen-sulfur co-doping, transition metal technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of scarcity and high price hindering the large-scale practical application of batteries, and achieve The effects of abundant reserves, good conductivity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a nitrogen-doped carbon coated transition metal nanosulfide electrochemical oxygen catalyst, the specific operation steps are as follows:

[0031] (1) 2,6-diacetylpyridine 1.3 g was placed in 150 mL of flat bottom flask, and 50 mL of anhydrous ethanol was added to the flat bottom flask, stirred until 2,6-diacetylpyridine completely dissolved, according to acetyl And the molar ratio of the amino group was 1: 1 to 1.99 g of 2,2'-di aminoisulfide sulfonthionic ether, stirred to completely dissolve, add 0.1 g of ohoxic acid to the flat flask, stirred for 30 min, and turn the flask to the oil bath. The temperature rose to 60 ° C, reacted at a constant temperature stirring for 10 hours;

[0032](2) After the reaction is cooled to room temperature, then 1.90 g of hexahydrate chloride is added to the room temperature, and the reaction is added to 12 hours while stirring, and the obtained substance after the reaction is removed by a rotary evaporator to evapor...

Embodiment 2

[0036] A method for preparing a nitrogen-doped carbon coated transition metal nanosulfide electrochemical oxygen catalyst, the specific operation steps are as follows:

[0037] (1) 2,6-diacetylpyridine 1.3 g was placed in 150 mL of flat flask, and 50 ml of organic solvent anhydrous ethanol was added to the flat flask, stirred until 2,6-diacetylpyridine completely dissolved, press The acetyl and the molar ratio of the amino group was added to 1.98 g of the sulfur-containing amino monomer 4,4-di-diiminary thion ether, stirred to completely dissolve, add 0.1 g of ohoxic acid to the flat flask, stirred for 30min, and turn the flask In the oil bath, heated to 80 ° C, reacted at a constant temperature stirring for 12 hours;

[0038] (2) After the step (1), the resulting solution was cooled to room temperature, and 2.16 g of the transition metal-containing inorganic salt hexahydrachloride was added while stirring, 10 hours of reaction at room temperature, and the obtained substance was r...

Embodiment 3

[0043] A method for preparing a nitrogen-doped carbon coated transition metal nanosulfide electrochemical oxygen catalyst, the specific operation steps are as follows:

[0044] (1) 2,6-diacetylpyridine 1.0 g was placed in three 150 ml flat flasks, and 50 ml of organic solvent anhydrous ethanol was added to the flat bottom flask, stirred until 2,6-diacetylpyridine is completely The molar ratio of the acetyl group and the amino group was added to 1.31 g of the sulfur-containing amino monomer 2,2'-di-diiminated aminogenated 1.31 g, stirred to completely dissolve, and 0.1 g of ohoxic acid was added to the flat bottom flask, stirred for 30min , Turn the flask to the oil bath, warmed to 100 ° C, reacted at a constant temperature stirred for 8 hours;

[0045] (2) After the reaction is cooled to room temperature after reacting step (1), 3.6 g, 1.2 g, 0.4 g of a transition metal hexahydride-containing nickel-containing nickel-containing nickel-containing nickel-containing nickel-containing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com