A two-dimensional zinc single atom/carbon nitrogen composite material and its preparation method and application

A composite material, atomic technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as small pores, loss of active sites, and difficulty in electrolyte diffusion, achieving low cost, high oxygen reduction catalytic activity, and improved catalytic activity. The effect of atom utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

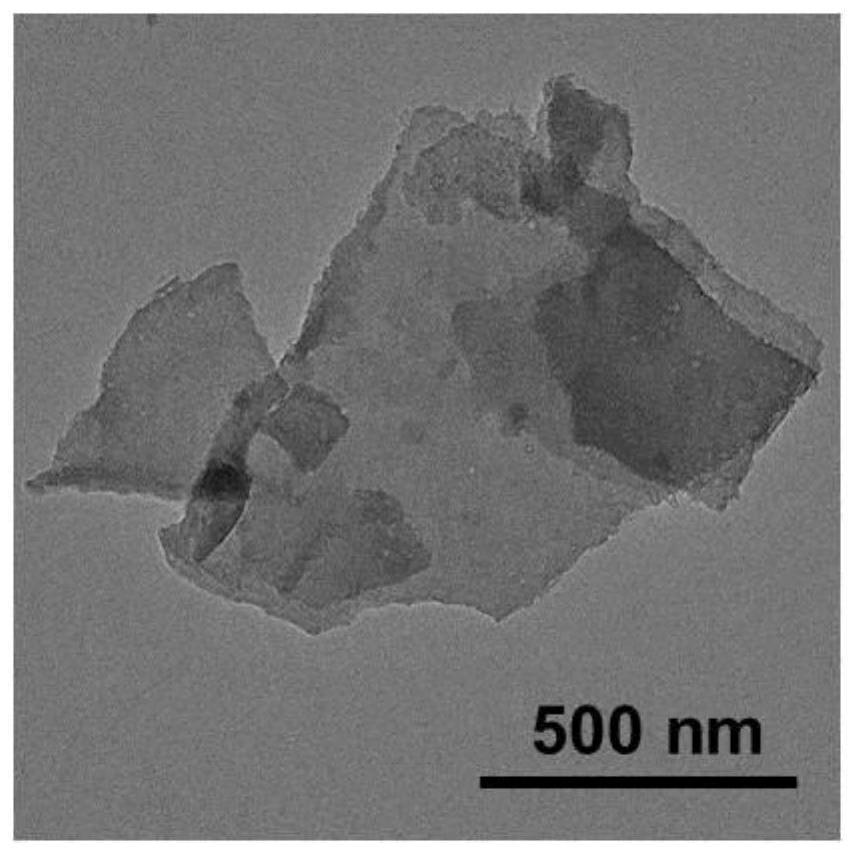

[0044] (a) Preparation of sheet-like Zn-MOFs (Zn-TCPP)

[0045] Dissolve 0.008g of meso-tetra(4-carboxyphenyl)porphine [meso-Tetra(4-carboxyphenyl)porphine (TCPP)] (0.01mmol) in 1mL of ethanol and 3mL of N,N-dimethylformamide [N , N-Dimethylformamide (DMF)] mixture. At the same time, 0.009g of zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) (0.03mmol), 0.0016g pyrazine (0.02mmol) and 0.04g polyvinylpyrrolidone (PVP) were dissolved in a mixture of 3mL ethanol and 9mL DMF. Under vigorous stirring, the TCPP solution was added dropwise. After stirring evenly, transfer it to a 20mL glass vial with a cover, hydrothermally react in an oven at 80°C for 8 hours, cool to room temperature, centrifuge, wash with ethanol three times, and dry in an oven at 80°C for 2 hours to obtain a purple Zn-TCPP compound;

[0046] (b) Preparation of two-dimensional zinc single atom / carbon nitrogen composite oxygen reduction electrocatalyst Zn / CN

[0047] Get a certain amount of Zn-TCPP compound obtained in ste...

Embodiment 2

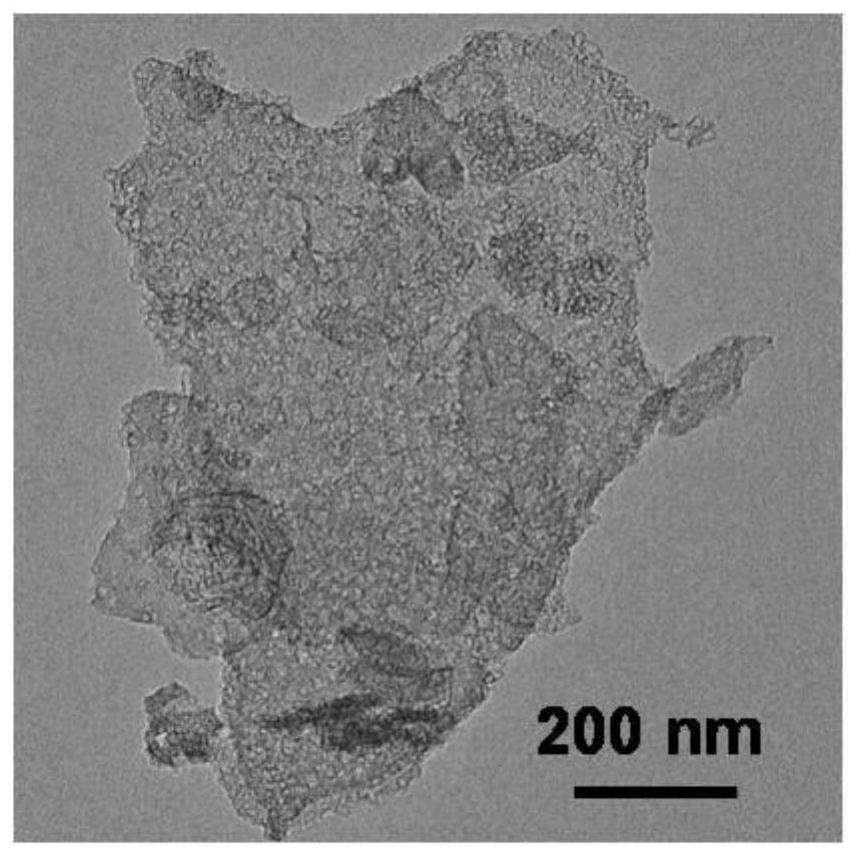

[0049] (a) Preparation of sheet-like Zn-MOFs (ZIF)

[0050] Dissolve 0.22 g of 2-methylimidazole in 16 mL of deionized water. At the same time, 0.072g zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O), 0.22g of 1-methylimidazole was dissolved in 4mL of deionized water. With vigorous stirring, the 2-methylimidazole solution was added dropwise. After stirring evenly, transfer it to a 40mL glass bottle with a cover, and conduct a hydrothermal reaction in an oven at 25°C for 6 hours. After the reaction, centrifuge, wash with ethanol three times, and dry in an oven at 80°C for 2 hours to obtain a white ZIF compound;

[0051] (b) Preparation of two-dimensional zinc single atom / carbon nitrogen composite oxygen reduction electrocatalyst Zn / CN

[0052] Get a certain amount of ZIF compound obtained in step (a) and place it in a porcelain boat after being ground, and use an inert gas as a protective gas in a tube furnace with a gas flow rate of 50mL min -1 , 5℃min -1 The heating rate was heated ...

Embodiment 3

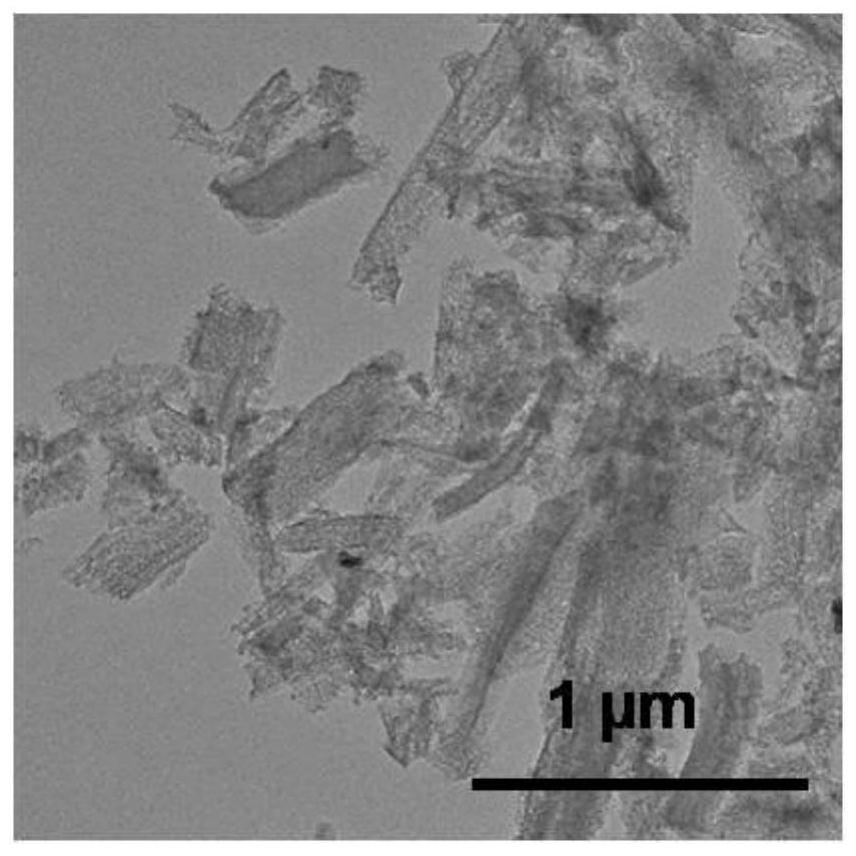

[0054] (a) Preparation of sheet-like Zn-MOFs (Zn-bpydc)

[0055] 0.024 g of 2,2'-bipyridine-5,5'-dicarboxylic acid (2,2'-Bipyridine-5,5'-dicarboxylic acid, bpydc) was dissolved in 5 mL of deionized water. At the same time, 0.118g zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) Dissolve in 5 mL deionized water. Under vigorous stirring, the 2,2'-bipyridine-5,5'-dicarboxylic acid solution was added dropwise. Stir evenly and transfer to a 50mL reaction kettle, hydrothermally react in an oven at 150°C for 8 hours, cool to room temperature, centrifuge, wash with ethanol three times, and dry in an oven at 80°C for 2 hours to obtain a white Zn-bpydc compound;

[0056] (b) Preparation of two-dimensional zinc single atom / carbon nitrogen composite oxygen reduction electrocatalyst Zn / CN

[0057] Get a certain amount of Zn-bpydc compound obtained in step (a) and place it in a porcelain boat after being ground, use an inert gas as a protective gas in a tube furnace, and the gas flow rate is 50mLmin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com