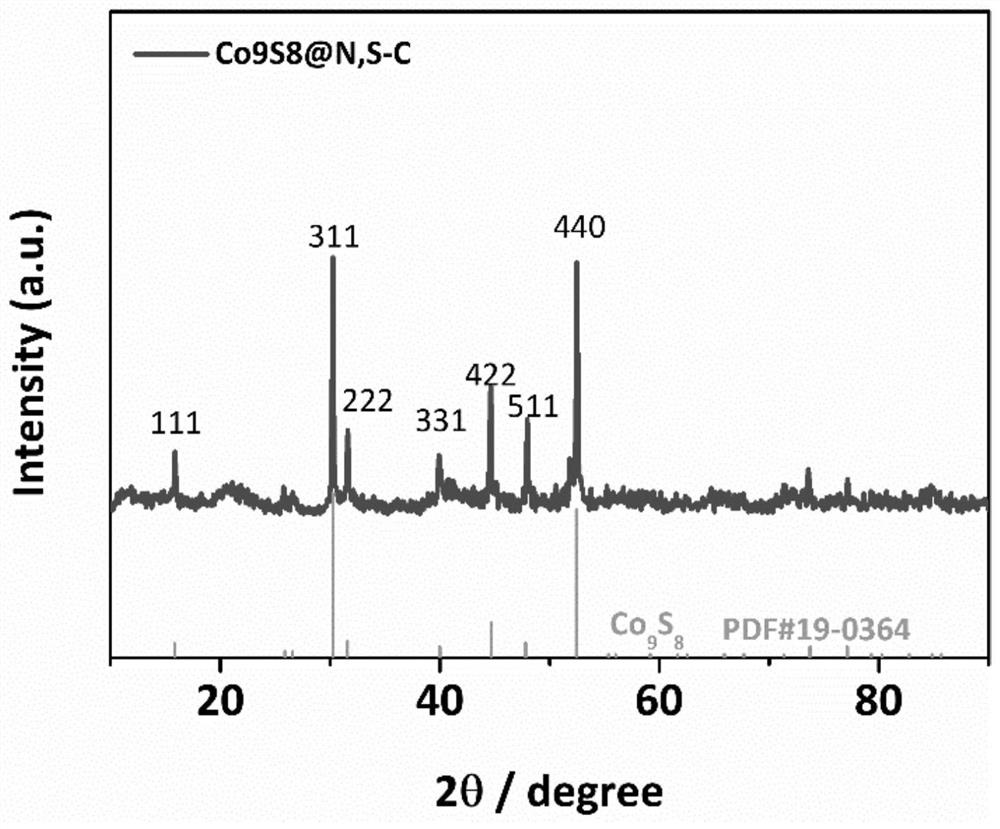

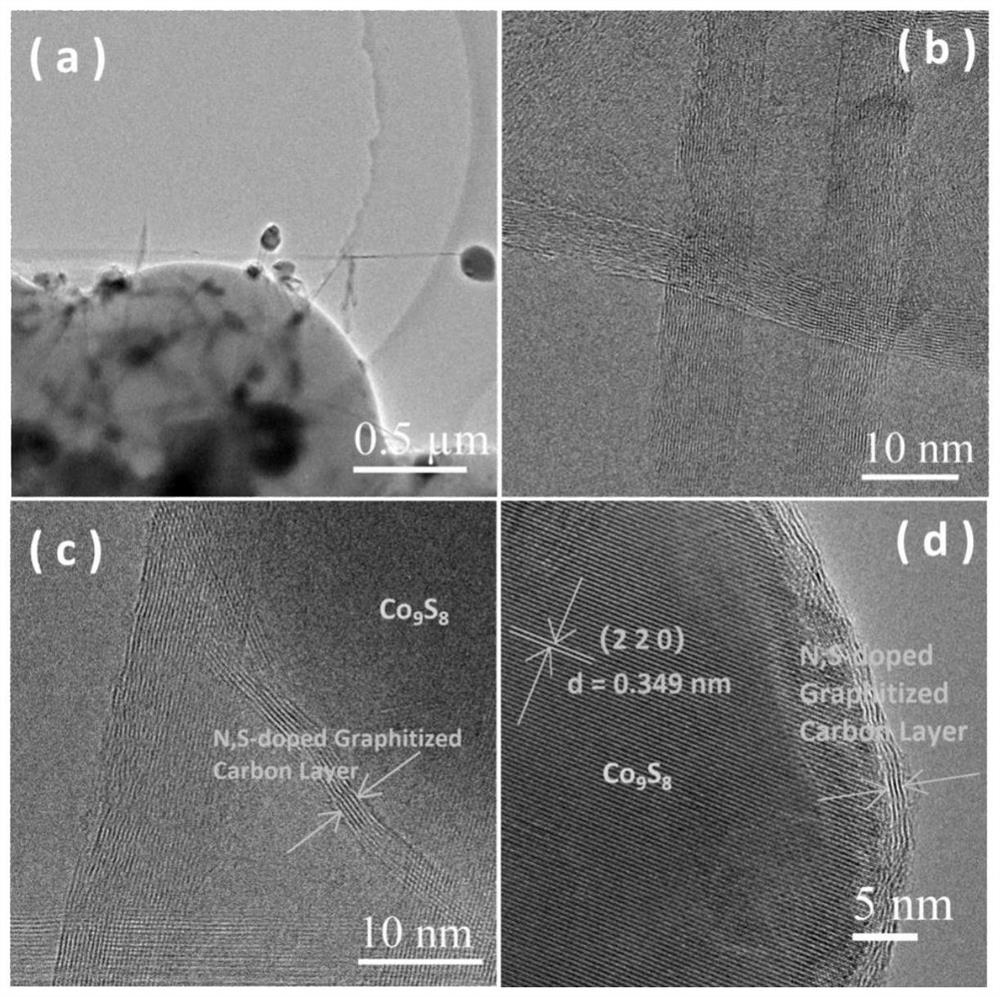

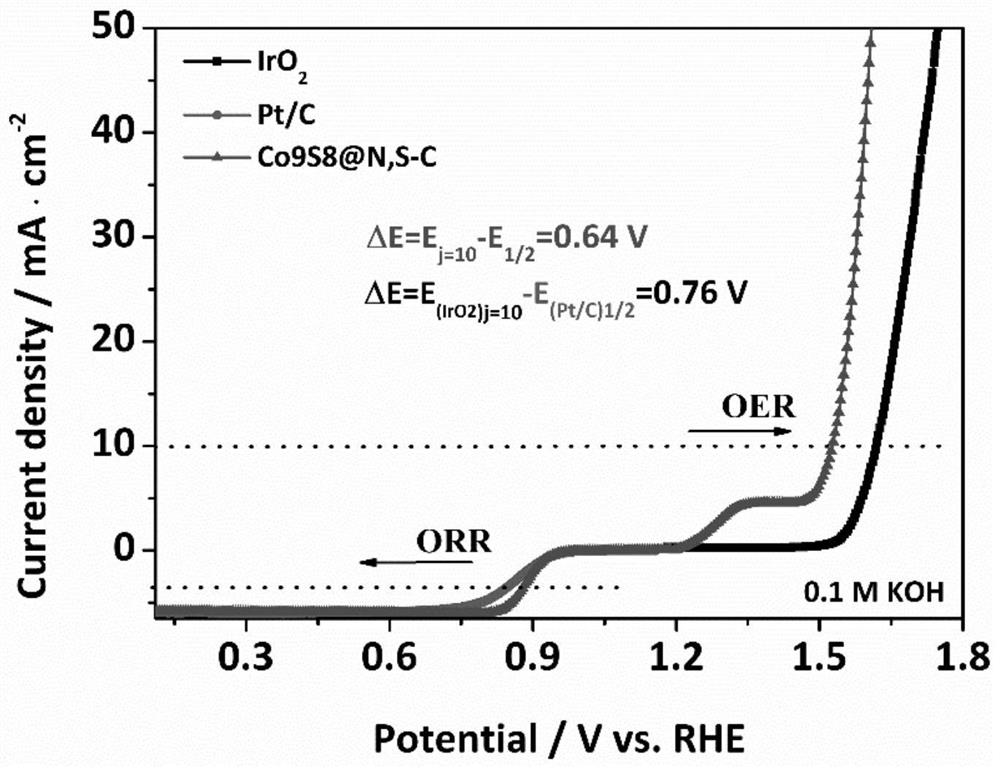

A kind of preparation method of nitrogen-sulfur co-doped carbon-coated transition metal nano-sulfide electrochemical oxygen catalyst

A technology of nitrogen-sulfur co-doping and transition metals, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of scarcity and high price that hinder the large-scale practical application of batteries, and achieve Rich reserves, good electrical conductivity, and many surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a nitrogen-sulfur co-doped carbon-coated transition metal nano-sulfide electrochemical oxygen catalyst, the specific operation steps are as follows:

[0031] (1) Put 1.3 g of 2,6-diacetylpyridine into a 150ml flat-bottomed flask, measure 50ml of absolute ethanol and add it to the flat-bottomed flask, stir until 2,6-diacetylpyridine is completely dissolved, according to the acetyl group Add 1.99 g of 2,2'-diaminodiphenyl disulfide in a molar ratio of 1:1 to amino group, stir until completely dissolved, add 0.1 g of oxalic acid to the flat-bottomed flask, stir for 30 min, transfer the flask to an oil bath, The temperature was raised to 60°C, and the reaction was carried out under constant temperature stirring for 10 hours;

[0032](2) the obtained solution after the reaction in step (1) was cooled to room temperature, 1.90 g of cobalt chloride hexahydrate was added while stirring, and the room temperature was reacted for 12 hours. After the reaction...

Embodiment 2

[0036] A method for preparing a nitrogen-sulfur co-doped carbon-coated transition metal nano-sulfide electrochemical oxygen catalyst, the specific operation steps are as follows:

[0037] (1) Put 1.3 g of 2,6-diacetylpyridine into a 150ml flat-bottomed flask, measure 50ml of anhydrous ethanol as an organic solvent and add it to the flat-bottomed flask, stir until 2,6-diacetylpyridine is completely dissolved, press The molar ratio of acetyl group and amino group is 1:1, add 1.98g of sulfur-containing amino monomer 4,4-diaminodiphenyl sulfide, stir until completely dissolved, add 0.1g oxalic acid to the flat-bottomed flask, stir for 30min, turn the flask In an oil bath pot, the temperature is raised to 80°C, and the reaction is carried out under constant temperature stirring for 12 hours;

[0038] (2) the obtained solution after the step (1) reaction is cooled to room temperature, 2.16g of transition metal-containing inorganic salt ferric trichloride hexahydrate is added while s...

Embodiment 3

[0043] A method for preparing a nitrogen-sulfur co-doped carbon-coated transition metal nano-sulfide electrochemical oxygen catalyst, the specific operation steps are as follows:

[0044] (1) Put 1.0 g of 2,6-diacetylpyridine into three 150ml flat-bottomed flasks respectively, measure 50ml of organic solvent dehydrated ethanol and add it to the flat-bottomed flask, and stir until 2,6-diacetylpyridine is completely Dissolve, add 1.31g of sulfur-containing amino monomer 2,2'-diaminodiphenyl sulfide according to the molar ratio of acetyl group and amino group 1:1, stir until completely dissolved, add 0.1g oxalic acid to the flat-bottomed flask, stir for 30min , transfer each flask to an oil bath, heat up to 100°C, and react under constant temperature stirring for 8 hours;

[0045] (2) cooling the obtained solution after the step (1) reaction to room temperature, adding 3.6g, 1.2g, 0.4g of transition metal-containing nickel dichloride hexahydrate to the obtained material in the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com