Self-supporting MXene/MWCNT flexible composite film, and preparation method and application thereof

A composite film, self-supporting technology, used in cable/conductor manufacturing, hybrid/electric double-layer capacitor manufacturing, equipment for manufacturing conductive/semiconducting layers, etc. Fast transport, affecting the specific capacitance and rate performance of MXene electrode materials, poor electrochemical performance, etc., to achieve the effect of retaining physical and chemical structural integrity, improved storage and transport performance, and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

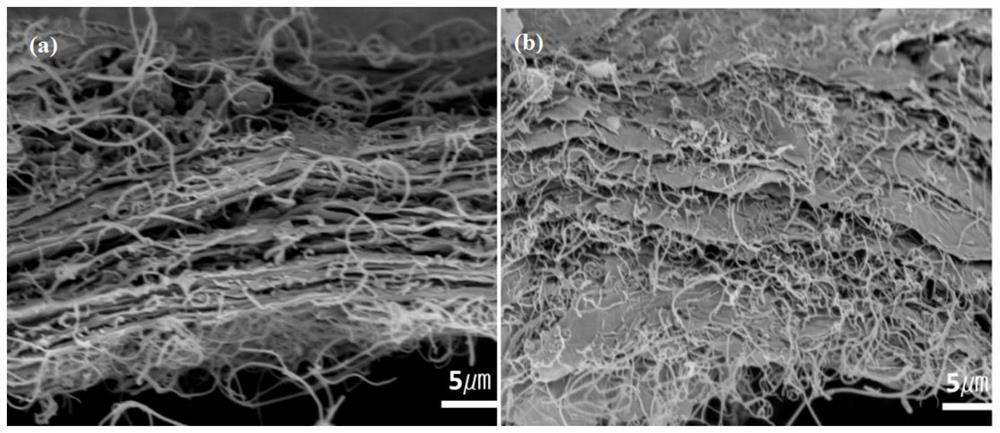

[0036] The invention provides a method for preparing a self-supporting MXene / MWCNT flexible composite film, comprising the following steps;

[0037] Ti 2 CT x The MXene colloidal solution is first filtered on the composite fiber filter membrane to form the first film layer;

[0038] performing a second filtration on the first film layer of the multi-walled carbon nanotube dispersion to form a first MWCNT layer;

[0039] On the first MWCNT layer, repeat the first filtration and the second filtration in sequence, and finally filter the Ti 2 CT x MXene colloidal solution to obtain a composite film;

[0040] After the composite film is freeze-dried, the composite fiber filter membrane is removed to obtain the self-supporting MXene / MWCNT flexible composite film.

[0041] In the present invention, Ti 2 CT x The MXene colloidal solution is first filtered on the composite fiber filter membrane to form the first film layer.

[0042] In the present invention, the composite fi...

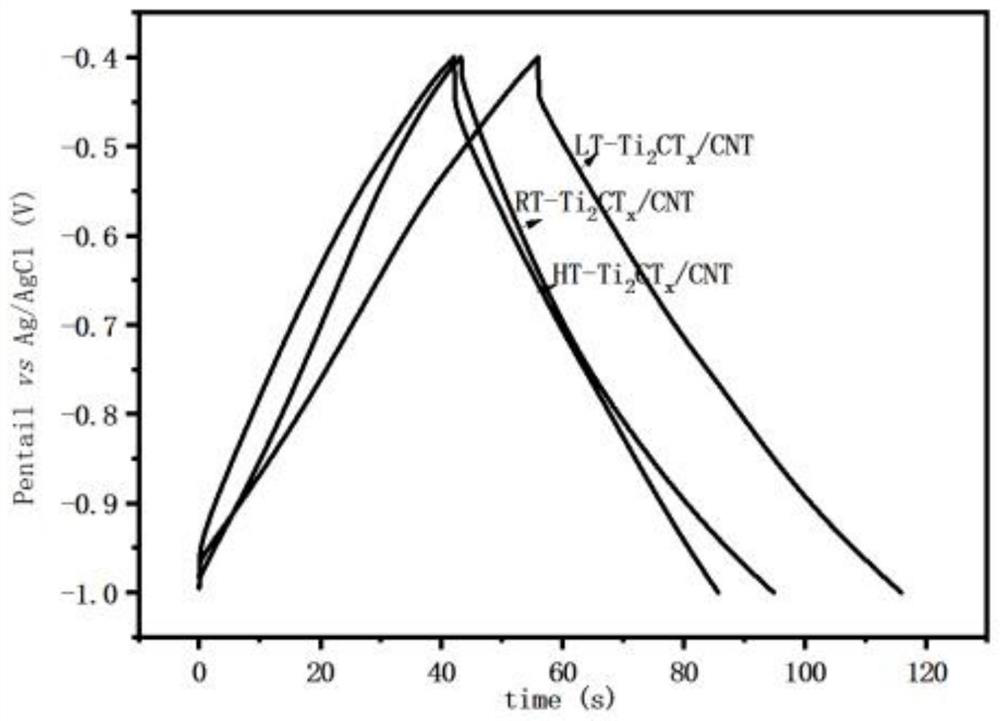

Embodiment 1

[0090] (1) Add 1g LiF to 20mL 6M HCl solution, stir and react in a 100mL Teflon beaker for 30min to prepare an acidic hydrogen fluoride solution;

[0091] (2) The ceramic material MAX phase 1g Ti 2 AlC powder (200 mesh) was added to the solution in step (1), the stirring speed was 250rpm, the temperature was 35°C, and the reaction time was 72h;

[0092] (3) Add 60 mL of deionized water to the step (2) at the end of the reaction, put it into four 50 mL centrifuge tubes, centrifuge at a speed of 3500 rpm, and wash with deionized water until the pH value is 6;

[0093] (4) Add alcohol with a purity of 99.99% in step (3), and transfer to a gas collecting bottle for ultrasonic stripping. At the same time, an inert gas is introduced to prevent MXene from being oxidized during the stripping process;

[0094] (5) Step (4) stripped Ti 2 CT x Transfer the solution to a 50mL centrifuge tube, vibrate manually for further layering, and centrifuge to get the supernatant, the color of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com