A kind of lead-acid battery grid fatigue life simulation detection device and detection method

A technology of fatigue life and detection device, which is used in measuring devices, using repetitive force/pulsation force to test the strength of materials, instruments, etc. problem, to achieve the effect of simple structure, easy operation and stable performance

Active Publication Date: 2022-07-12

山东犀力电源有限公司

View PDF34 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since the grid is located inside the lead-acid battery, the repeated extrusion load it receives comes from the charge-discharge cycle process of the lead-acid battery. In the current known technical solutions, it is difficult to simulate the strength performance of the grid under high-fidelity conditions. effective testing

Chinese patent CN201410007485 discloses a rapid detection method for air holes in battery grid ribs, but this method mainly finds air hole defects through single extrusion of ribs, and cannot conveniently and accurately simulate test grids repeatedly subjected to repeated stresses. Fatigue life under extrusion load

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0035] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

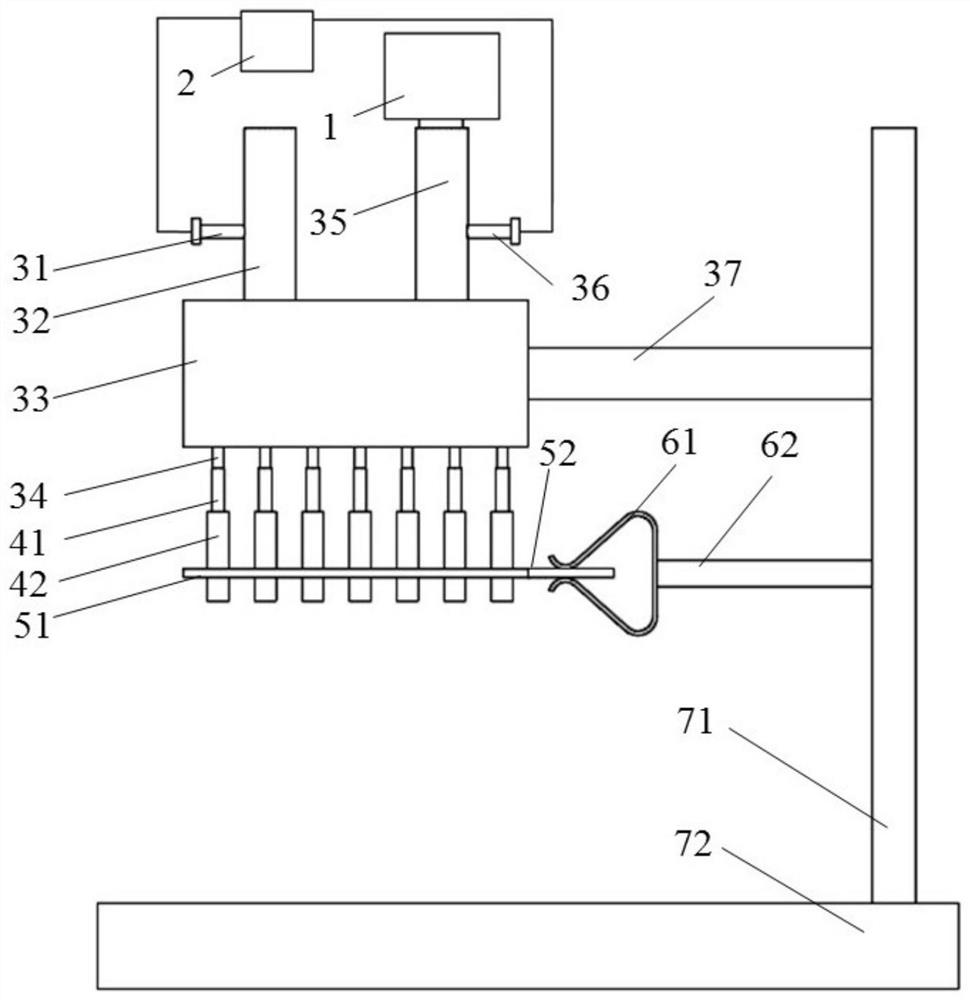

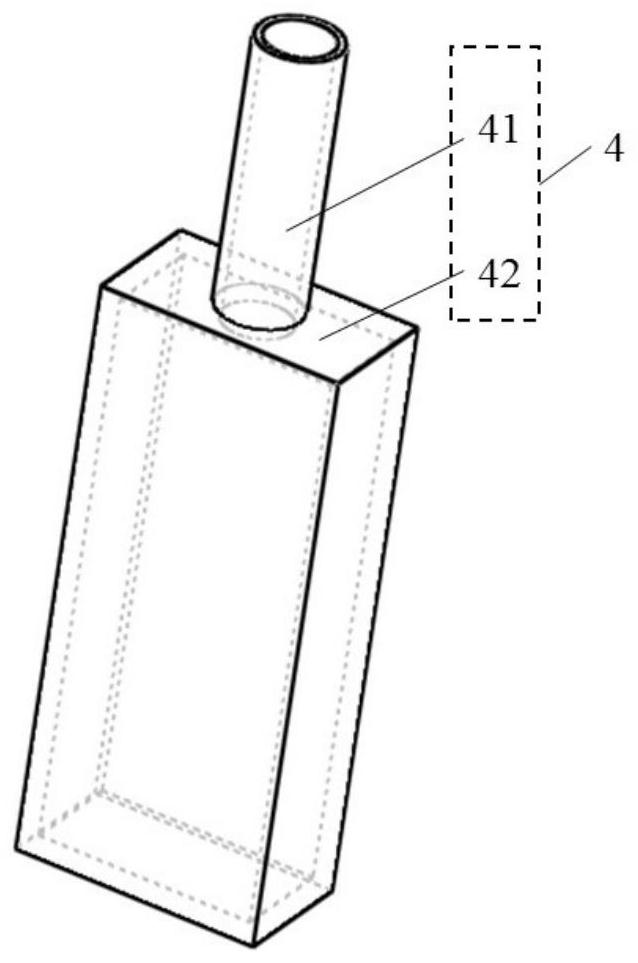

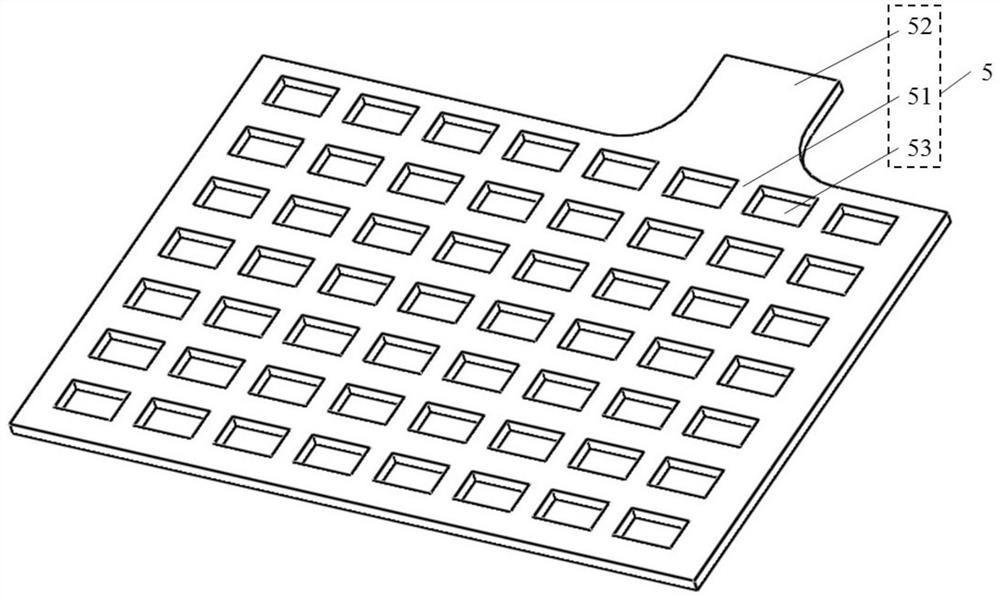

The invention provides a lead-acid battery grid fatigue life simulation detection device, which includes a high-pressure air source, a controller, an air guide assembly, a rubber expansion bag, a clamp and a support. The high-pressure air source is used to provide air pressure for the air guide cavity. The controller is used to control the opening and closing of the valve, the air guide cavity is respectively connected with the first connecting pipe, the second connecting pipe and the air guide branch pipe, and the air guide branch pipe provides air pressure for the rubber bag body; the invention also provides a lead-acid battery plate The grid fatigue life simulation detection method includes the steps of placing the rubber expansion bag inside the grid, continuously inflating and exhausting the rubber bag body to alternately load and unload pressure load to the grid, stopping the test and recording the results. The detection device provided by the invention is simple in structure, stable in performance and easy to customize, and the corresponding detection method is easy to operate, has good accuracy and saves gas sources.

Description

technical field [0001] The invention relates to the field of lead-acid batteries, in particular to a method for simulating and analyzing the grid strength of lead-acid batteries considering material expansion effect. Background technique [0002] Lead-acid batteries are widely used in various departments of the national economy and national defense and military due to their low cost, good safety performance, and stable performance. However, the actual cycle life of lead-acid batteries is low, often only about 500 cycles, far below the level that can be achieved by its theoretical limit. The cycle life of lead-acid batteries is affected by many factors. One of the key factors is the impact on the grid caused by the continuous expansion and contraction of the active material volume during the charging and discharging process of the lead-acid battery. Since the grids are mostly made of lead or lead-tin alloys with soft texture and small elastic modulus by stamping or continuou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N3/36G01N3/02G01N3/04

CPCG01N3/36G01N3/02G01N3/04G01N2203/0073G01N2203/0282Y02E60/10

Inventor 张翮辉常春平游浩林

Owner 山东犀力电源有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com