Vacuum corrugated pipe automatic welding equipment

A technology of automatic welding and welding equipment, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficulty in keeping two bellows rotating synchronously, and the extrusion force of the two bellows pipe bodies is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

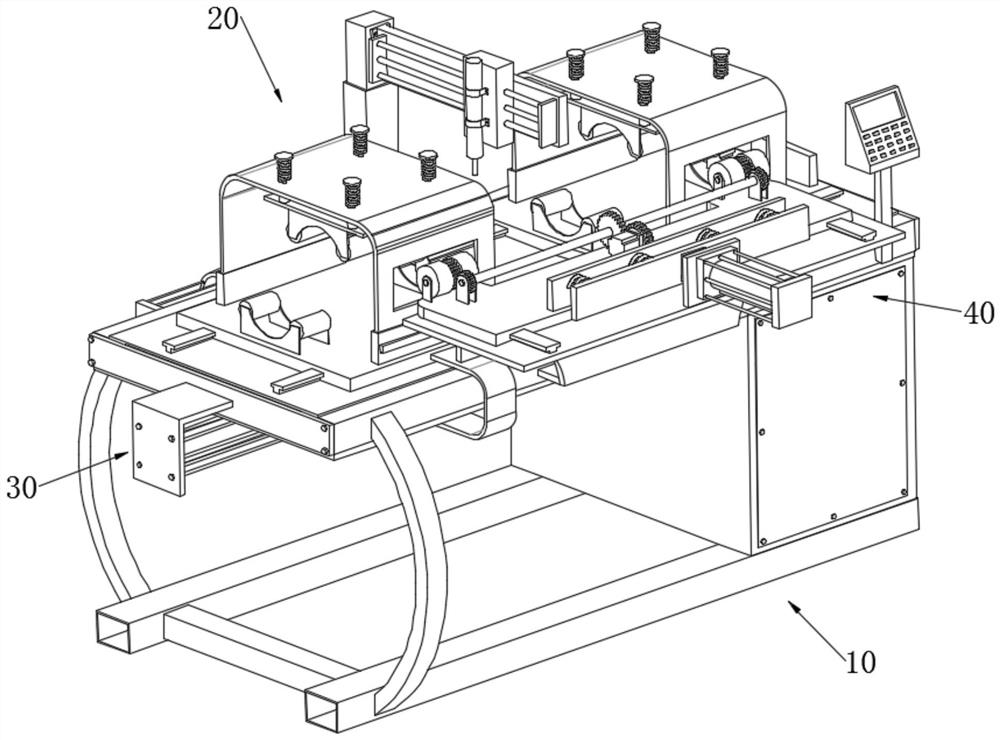

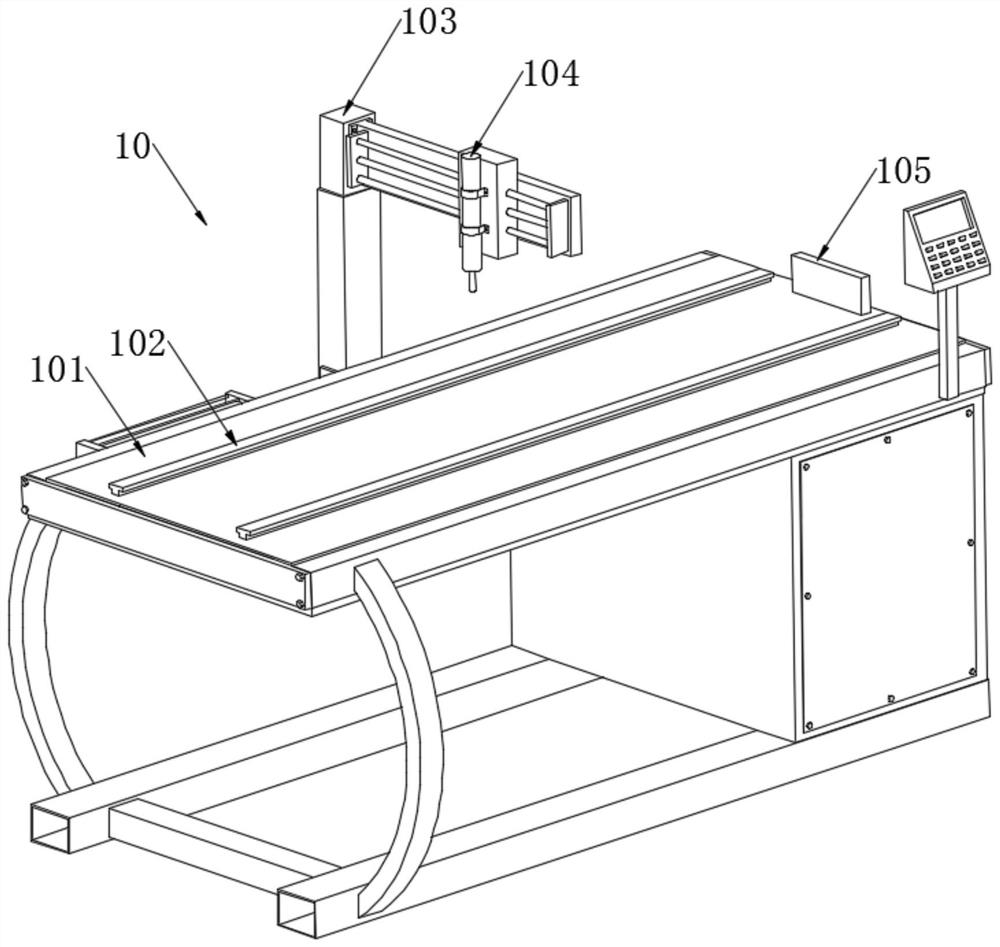

[0034] Example: see figure 1 and figure 2 , a vacuum bellows automatic welding equipment, including a welding equipment body 10, a positioning mechanism 20 located above the welding equipment body 10, a driving mechanism 30 located inside the welding equipment body 10, and a welding equipment body 10 for controlling the rotation of the bellows The adjustment mechanism 40; the welding equipment body 10 includes a worktable 101, a three-axis positioning mechanism 103 located on the top surface of the workbench 101, and a welding torch 104 is connected to the three-axis positioning mechanism 103; the three-axis positioning mechanism 103 can be positioned along X, Y, Z The welding torch 104 is moved in three directions to facilitate accommodation of different sizes and lengths of bellows.

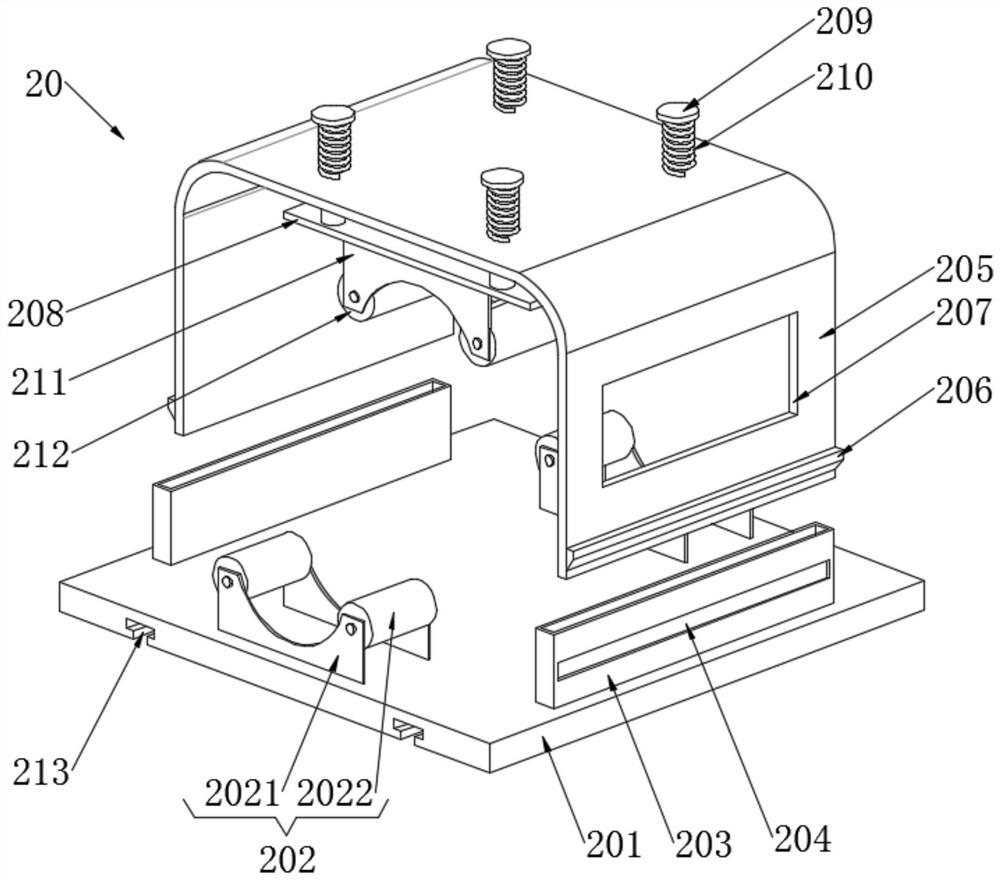

[0035] see figure 2 and image 3The positioning mechanism 20 includes two moving parts 201 located on the front and rear sides of the top of the workbench 101 and capable of sliding along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com