System and method for testing compressive strength of mining microcapsule inhibitor

A technology of compressive strength and test system, which is applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc., which can solve the problem of small particles of microcapsule inhibitors and the inability to accurately restore microcapsules. The problem of the pressure of the agent, the easy to break under pressure and other problems, to achieve the effect of accurate measurement of compressive strength, rapid realization of multiple measurements, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

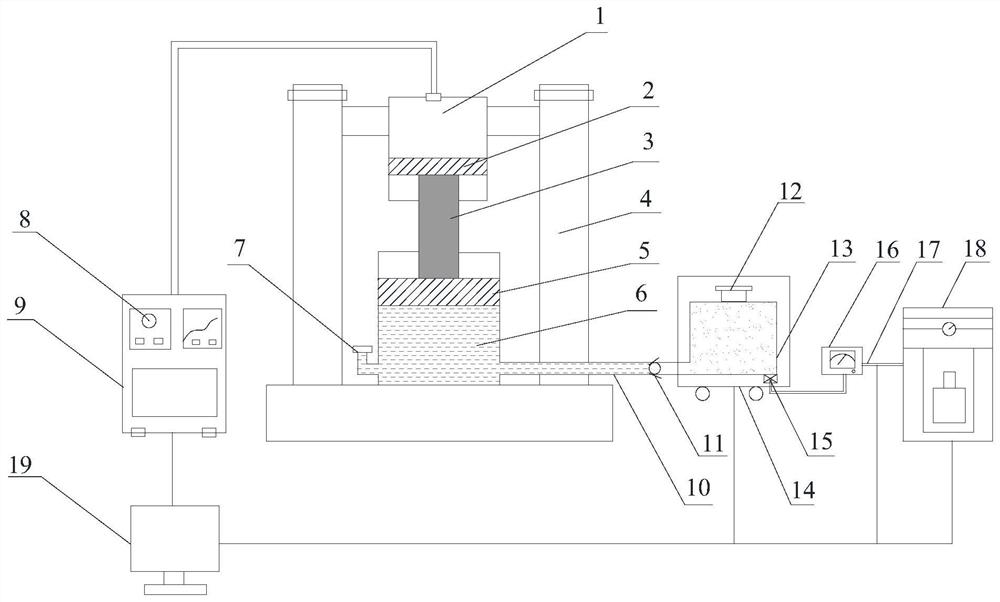

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] The compressive strength test system of mine-used microcapsule inhibitor includes pressure control part, test part, detection part and centralized electric control part.

[0030] Such as figure 1 As shown, the pressure control part includes a hydraulic pump station 9 and a main loading hydraulic cylinder 1; the hydraulic pump station 9 is provided with a pressure gauge 8, and the hydraulic pump station 9 communicates with the main loading hydraulic pressure through a pump pressure output pipeline and an oil return pipeline. The cylinder 1 is installed and connected; the cylinder body end of the main loading hydraulic cylinder 1 is fixedly installed on the test platform through the support frame 4, and the piston rod 3 of the main loading hydraulic cylinder 1 protrudes vertically downward.

[0031] The test part includes an auxiliary loading hydraulic cylinder 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com