Nanoscale oxide reinforced low-activation steel composite material and preparation method thereof

A nano-scale oxide and low-activation steel technology, applied in the field of iron and steel metallurgy, can solve problems such as complex process, poor economy, and industrial production restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

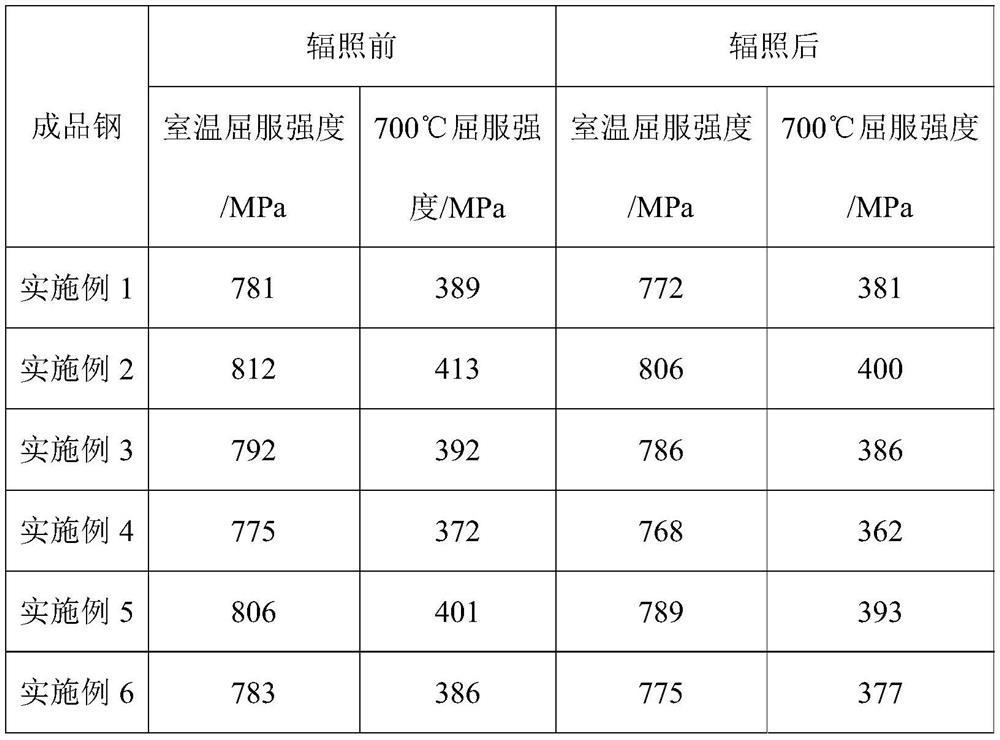

Examples

preparation example Construction

[0035] The preparation method of the nano-scale oxide reinforced low-activation steel composite material of the present invention comprises the following steps:

[0036] (1) Preparation of hollow nano-oxide particles: Nanoscale Y with a size of 20-30 nm 2 o 3 , Nanoscale Al 2 o 3 Place the nano-sized particles A in a ball mill for ball milling solid solution, the ball-to-material ratio is 10:(1-1.5), the ball-milling speed is 400-450 rpm, the ball-milling time is 3-3.5 hours, and the ball-milling atmosphere is atmospheric. Wherein the nanoscale particle A is nanoscale TiO 2 and / or nanoscale ZrO 2 . When nanoscale particle A is nanoscale TiO 2 or nanoscale ZrO 2 , nanoscale Y 2 o 3 , Nanoscale Al 2 o 3 Carry out ball milling and solid solution with nanoscale particle A according to the mass ratio of 1:(2.5~3):(1.5~2); when nanoscale particle A is nanoscale TiO 2 and nanoscale ZrO 2 , nanoscale Y 2 o 3 , Nanoscale Al 2 o 3 and nano-sized particles A according to...

Embodiment 1

[0044] The preparation method of the nano-scale oxide reinforced low-activation steel composite material in this embodiment includes the following steps:

[0045] (1) Preparation of hollow nano-oxide particles: Nanoscale Y with a size of 20-30 nm 2 o 3 , Nanoscale Al 2 o 3 Put nano-sized particles A in a ball mill for ball milling solid solution, the ball-to-material ratio is 10:1, the ball milling speed is 400 rpm, the ball milling time is 3.5 hours, and the ball milling atmosphere is atmospheric. Wherein the nanoscale particle A is nanoscale TiO 2 . Nanoscale Y 2 o 3 , Nanoscale Al 2 o 3 Ball milling and solid solution with nano-sized particles A according to the mass ratio of 1:2.5:2.

[0046] Put the ball-milled solid-dissolved oxide particles in NaOH solution for hollow out erosion, and then wash the hollowed out particles with clean water and dry them at a drying temperature of 110°C for 3 hours, where the concentration of NaOH is 5mol / ml , nanoscale Y 2 o 3 ...

Embodiment 2

[0053] The preparation method of the nano-scale oxide reinforced low-activation steel composite material in this embodiment includes the following steps:

[0054] (1) Preparation of hollow nano-oxide particles: Nanoscale Y with a size of 20-30 nm 2 o 3 , Nanoscale Al 2 o 3 Put nano-sized particles A in a ball mill for solid solution by ball milling, the ball-to-material ratio is 10:1.5, the ball milling speed is 450 rpm, the ball milling time is 3 hours, and the ball milling atmosphere is atmospheric. Wherein the nanoscale particle A is nanoscale TiO 2 . Nanoscale Y 2 o 3 , Nanoscale Al 2 o 3 Ball mill solid solution with nano-sized particles A according to the mass ratio of 1:3:1.5.

[0055] Put the ball-milled solid-dissolved oxide particles in NaOH solution for hollow out erosion, and then wash the hollowed out particles with clean water and dry them at a temperature of 150°C for 2 hours, where the concentration of NaOH is 7mol / ml , nanoscale Y 2 o 3 , Nanoscale...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com