Novel soil heavy metal fixing agent and preparation method thereof

A technology of heavy metals and fixatives, applied in the field of soil remediation, can solve the problems of acidity of soil and low removal rate of heavy metals, and achieve the effects of increasing adsorption, increasing stability, and increasing contact points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

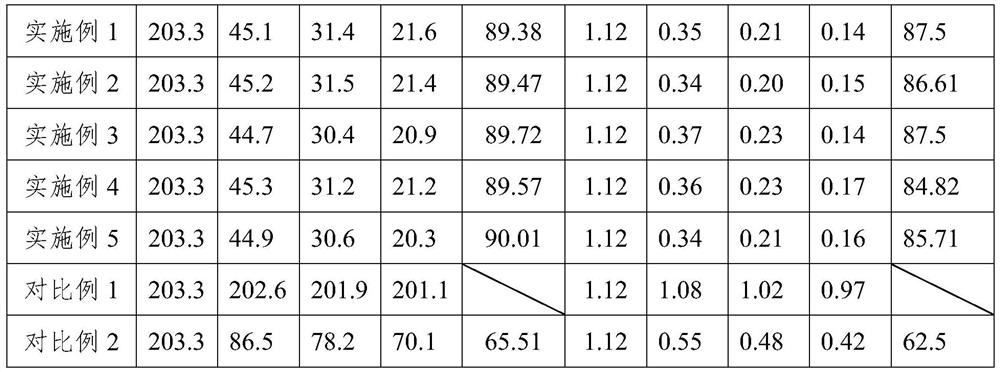

Examples

Embodiment 1

[0029] A preparation method of a novel soil heavy metal fixative, comprising the steps of:

[0030] (1) Preparation of oligomeric xanthan gum: putting 5g of xanthan gum into an ultrasonic processor with a power of 300W and a frequency of 10kHz for ultrasonic treatment for 2min to obtain oligomeric xanthan gum;

[0031] (2) Preparation of polyhydroxy ferric phosphate: Dissolve 10 g of ferric chloride in 600 g of 1,2-propylene glycol solvent, then add 20 g of phosphoric acid therein, and react at 30° C. for 2 h. After the reaction, the reaction product is filtered, washed, Drying, crushing and sieving to obtain polyhydroxy iron phosphate;

[0032] (3) Preparation of modified polyhydroxy iron phosphate: put 20g of polyhydroxy iron phosphate, 30g of vinyl silane coupling agent, and 200mL of toluene into the reaction kettle, and react at 100°C for 10h. After the reaction, the reaction product was Filtration, washing, drying, crushing and sieving to obtain modified polyhydroxy ferr...

Embodiment 2

[0036] A preparation method of a novel soil heavy metal fixative, comprising the steps of:

[0037] (1) Preparation of oligomeric xanthan gum: putting 5g of xanthan gum into an ultrasonic processor with a power of 300W and a frequency of 10kHz for ultrasonic treatment for 2min to obtain oligomeric xanthan gum;

[0038] (2) Preparation of polyhydroxy ferric phosphate: dissolve 10 g of ferric chloride in 900 g of 1,2-propylene glycol solvent, then add 25 g of phosphoric acid therein, and react at 40° C. for 2 h. After the reaction, the reaction product is filtered, washed, Drying, crushing and sieving to obtain polyhydroxy iron phosphate;

[0039] (3) Preparation of modified polyhydroxy iron phosphate: put 20g of polyhydroxy iron phosphate, 40g of vinyl silane coupling agent, and 200mL of toluene into the reaction kettle, and react at 120°C for 10h. After the reaction, the reaction product was Filtration, washing, drying, crushing and sieving to obtain modified polyhydroxy ferr...

Embodiment 3

[0043] A preparation method of a novel soil heavy metal fixative, comprising the steps of:

[0044] (1) Preparation of oligomeric xanthan gum: putting 5g of xanthan gum into an ultrasonic processor with a power of 300W and a frequency of 10kHz for ultrasonic treatment for 2min to obtain oligomeric xanthan gum;

[0045] (2) Preparation of polyhydroxy ferric phosphate: dissolve 10 g of ferric chloride in 850 g of 1,2-propylene glycol solvent, then add 35 g of phosphoric acid therein, and react at 35° C. for 2 h. After the reaction, the reaction product is filtered, washed, Drying, crushing and sieving to obtain polyhydroxy iron phosphate;

[0046] (3) Preparation of modified polyhydroxy iron phosphate: put 20g of polyhydroxy iron phosphate, 45g of vinyl silane coupling agent, and 200mL of toluene into the reactor, and react at 100°C for 10h. After the reaction, the reaction product was Filtration, washing, drying, crushing and sieving to obtain modified polyhydroxy ferric phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com