Ink for thermal printing paper and preparation method thereof

A heat-sensitive printing paper and ink technology, applied in the field of ink, can solve the problems of long drying time and achieve the effects of fast drying speed, shortened drying time and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

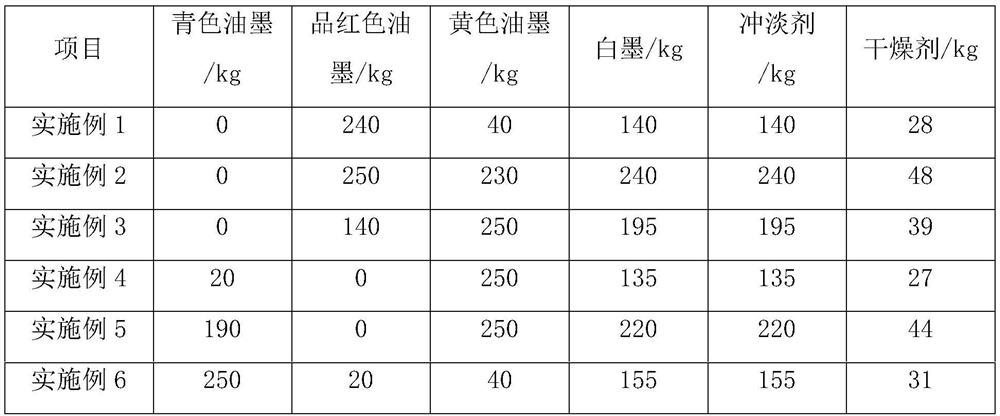

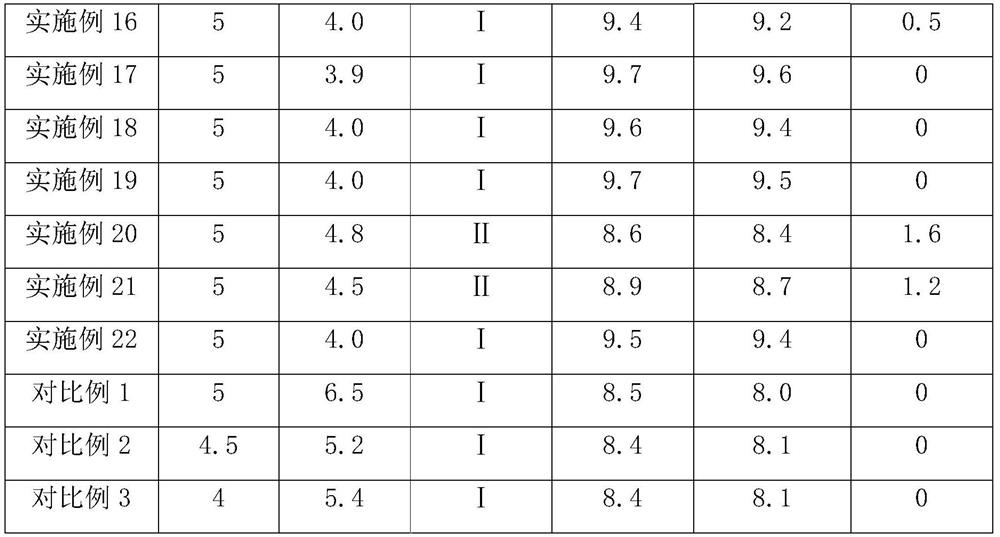

Examples

preparation example Construction

[0034] Preparation example of oil-absorbing xerogel

[0035] Lignin in the following raw materials was purchased from Pand (Shanghai) International Trading Co., Ltd.; isocyanate was purchased from Shandong Dada Chemical Co., Ltd., model PM200; tetrahydrofuran was purchased from Jinan Pulaihua Chemical Co., Ltd.; triethanolamine was purchased from Jinan Pulaihua Chemical Co., Ltd. Co., Ltd.; turpentine was purchased from Jinan Huijinchuan Chemical Co., Ltd.; other raw materials and equipment are all commercially available.

preparation example 1

[0036] Preparation Example 1: Oil-absorbing dry gel was prepared by the following method:

[0037] Ⅰ Weigh 0.1g lignin and 0.8g isocyanate and dissolve them in 8g tetrahydrofuran, then add 40g triethanolamine, stand at room temperature for 5h to obtain the initial gel;

[0038] II. The primary gel prepared in I was dried to constant weight at normal temperature and pressure to obtain oil-absorbing dry gel.

preparation example 2

[0039] Preparation Example 2: Oil-absorbing dry gel was prepared by the following method:

[0040] Ⅰ Dissolve 0.25g lignin and 0.2g isocyanate into 10g tetrahydrofuran, then add 10g triethanolamine, and leave it for 4h at room temperature to obtain the initial gel;

[0041] II. The primary gel prepared in I was dried to constant weight at normal temperature and pressure to obtain oil-absorbing dry gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com