Method and device for synthesizing aquacide dichloride

A synthesis method, the technology of diquat, is applied in the field of synthesis of diquat dichloride to achieve the effects of saving cost, improving production efficiency, extraction efficiency and extraction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

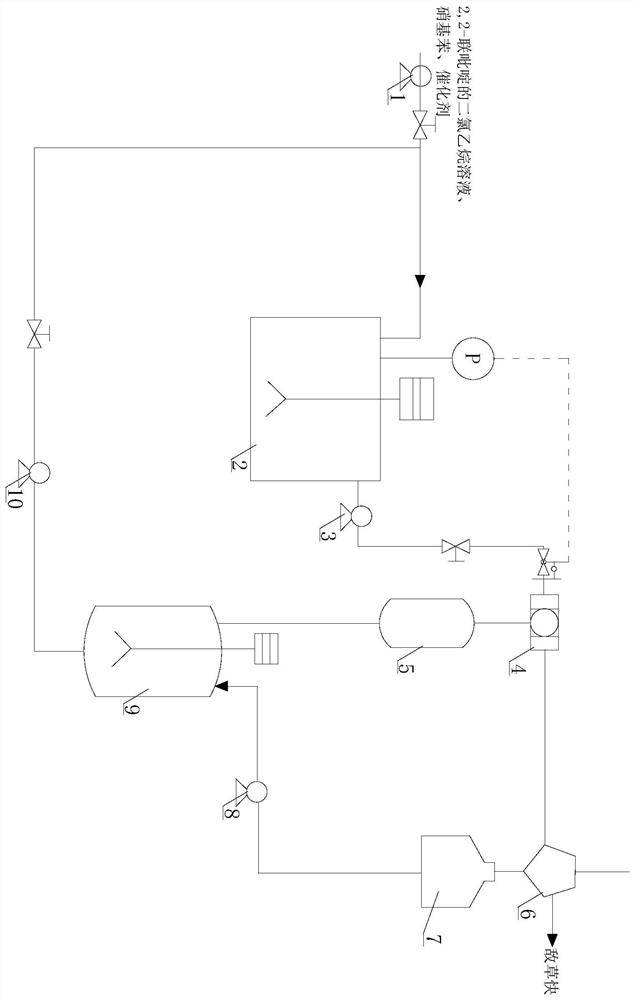

[0027] refer to figure 1 , dichloroethane, catalyst (K + content 0.5%, MgO content is 1%), nitrobenzene and 2,2-bipyridine mixed solution are driven into slurry bed reactor 2 through the first centrifugal pump 1, at a temperature of 145 ℃, pressure 1.5MP under the conditions of the reaction, the reaction material is pumped into the filter 4 through the second centrifugal pump 3, the catalyst enters the regenerator 5 for regeneration, and the reaction liquid enters the centrifugal extractor 6 for extraction and separation. The water phase is diquat. The organic phase enters the organic phase storage tank 7, and then enters the mixing tank 9 through the third centrifugal pump 8, and after mixing with the catalyst, enters the slurry bed reactor 2 through the fourth centrifugal pump 10 to continue the reaction. The yield is 95.6%.

Embodiment 2

[0029] Dichloroethane, catalyst (K+ content 3.5%, MgO content 5%), nitrobenzene and 2,2-bipyridine mixed solution are driven into the slurry bed reactor 2 through the first centrifugal pump 1, at a temperature of 145 ° C , under the condition of a pressure of 1.5MP, the reacted material is pumped into the filter 4 through the second centrifugal pump 3, the catalyst enters the regenerator 5 for regeneration, and the reaction liquid enters the centrifugal extractor 6 for extraction and separation. The water phase is diquat, organic The phase enters the organic phase storage tank 7, and then enters the mixing tank 9 through the third centrifugal pump 8, and after mixing with the catalyst, enters the slurry bed reactor 2 through the fourth centrifugal pump 10 to continue the reaction. The yield was 95.3%.

Embodiment 3

[0031] The mixture of dichloroethane, catalyst (K+ content 2%, MgO content 3.5%), nitrobenzene and 2,2-bipyridine is injected into the slurry bed reactor 2 through the first centrifugal pump 1, and the temperature is 200°C , the reaction under the condition of pressure 2.5MP, the material of the reaction is pumped into the filter 4 through the second centrifugal pump 3, the catalyst enters the regenerator 5 for regeneration, and the reaction liquid enters the centrifugal extractor 6 for extraction and separation. The water phase is diquat, organic The phase enters the organic phase storage tank 7, and then enters the mixing tank 9 through the third centrifugal pump 8, and after mixing with the catalyst, enters the slurry bed reactor 2 through the fourth centrifugal pump 10 to continue the reaction. The yield was 96.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com