Water mill for plane grinding

A technology of water mill and plane, which is applied to machine tools suitable for grinding workpiece planes, parts of grinding machine tools, grinding machines, etc. It can solve problems such as over-grinding, affecting service life, and affecting the surrounding environment, and achieves increased radiation heat transfer , enhance the heat absorption capacity, and the effect of heat dissipation is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

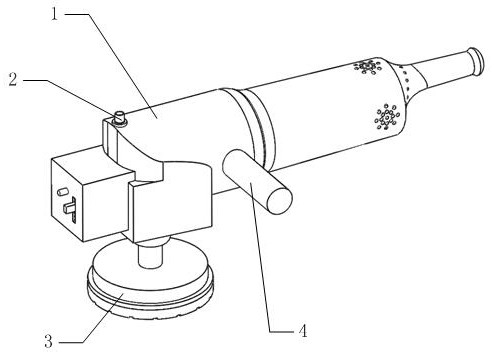

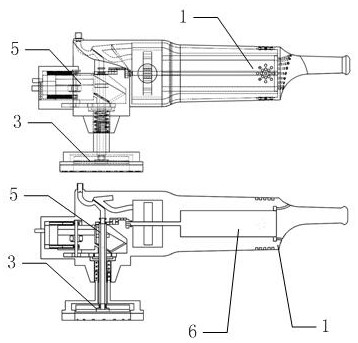

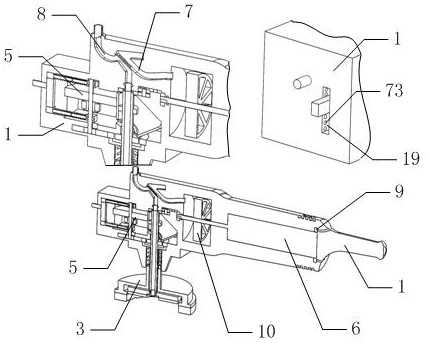

[0055] Such as figure 1 , 2 , 3, it includes a housing 1, a grinding mechanism 3, an auxiliary handle 4, a motor 6, a fan 10, and a second rotating shaft 40, wherein as Figure 5 As shown, the rear end of the housing 1 has a handle 28, and the front end of the housing 1 has a water injection port 2, and the housing 1 is provided with evenly distributed air intake holes 27 and exhaust holes 26; image 3 As shown, the motor 6 is installed in the housing 1, and is located at the rear end in the housing 1; as Figure 7 As shown, the fan 10 is fixedly installed on the output shaft of the motor 6, and is located in the housing 1; as Figure 7 , 8 As shown, the grinding disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com