Hazardous waste treatment system

A treatment system and hazardous waste technology, applied in grain treatment, solid waste removal, combustion methods, etc., can solve problems such as poor cooling efficiency, poor treatment efficiency, and secondary pollution of the environment, so as to improve treatment efficiency and avoid secondary pollution Pollution, the effect of improving the quality of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

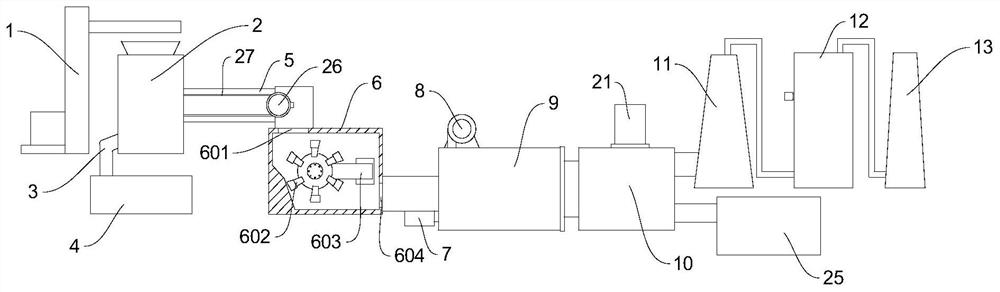

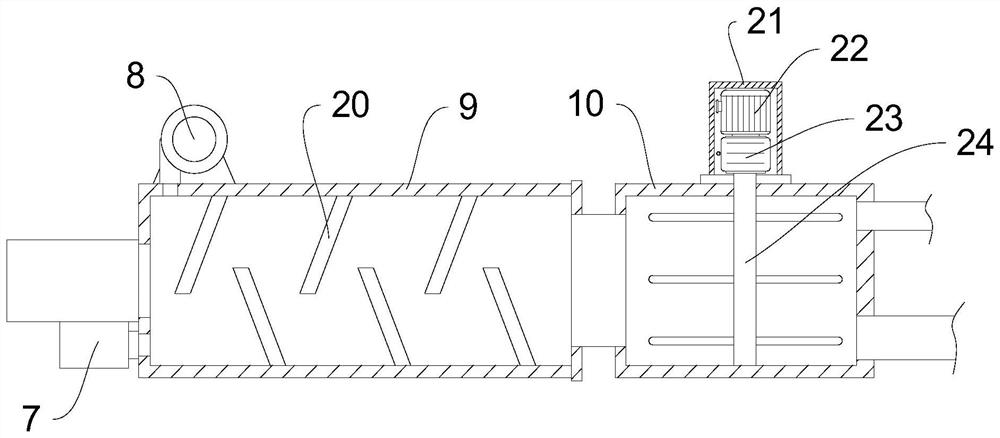

[0031] Please refer to Figure 1-Figure 3 , the embodiment of the present invention provides a hazardous waste treatment system, including a solid-liquid separation device, a crushing device, and an incineration device 9. The two sides of the solid-liquid separation device are respectively provided with a solid outlet and a liquid outlet. One end of the above-mentioned solid outlet is provided with a conveying device, the other end of the above-mentioned conveying device is connected with the above-mentioned crushing device, the side of the liquid outlet at the bottom of the above-mentioned solid-liquid separation device is connected with a liquid discharge pipe 3, and one end of the above-mentioned liquid discharge pipe 3 is provided with a waste liquid treatment Device 4, the discharge port 604 of the above-mentioned crushing device is connected with the feed port 601 of the above-mentioned incineration device 9 through a pipeline, the side of the above-mentioned incineration...

Embodiment 2

[0034] Please refer to figure 1 , in some embodiments of the present invention, it also includes a hoist 1, and the hoist 1 is arranged on one side of the solid-liquid separation device.

[0035] In the above embodiment, the hazardous waste can be transported to the solid-liquid separation device through the hoist 1, which facilitates the processing of the hazardous waste, has a high degree of automation, and effectively improves the processing efficiency of the hazardous waste.

Embodiment 3

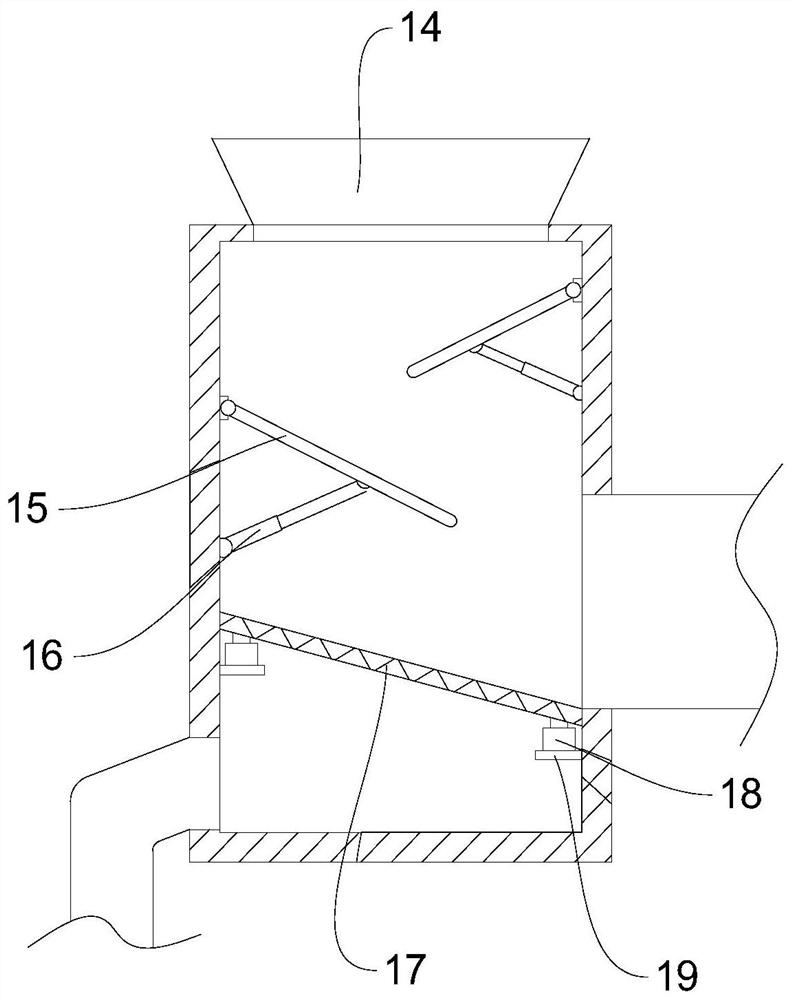

[0037] Please refer to figure 1 with figure 2 , in some embodiments of the present invention, the above-mentioned solid-liquid separation device includes a body 2, a dial 15, a screen 17 and a vibrating motor 18, the top of the body 2 is provided with a feed hopper 14, and one end of the dial 15 is movable. On both sides of the inner wall of the above-mentioned body 2, an electric cylinder 16 is provided at the bottom of the above-mentioned dial 15, and the fixed bottom of the above-mentioned electric cylinder 16 is movably arranged on the inner wall of the above-mentioned body 2, and the above-mentioned screen 17 is obliquely arranged at the lower part of the above-mentioned body 2, and the above-mentioned Vibration motor 18 is located at the bottom both sides of above-mentioned screen cloth 17, and the bottom of above-mentioned vibration motor 18 is provided with vibrating plate 19, and the side wall of above-mentioned vibrating plate 19 is connected with above-mentioned bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com