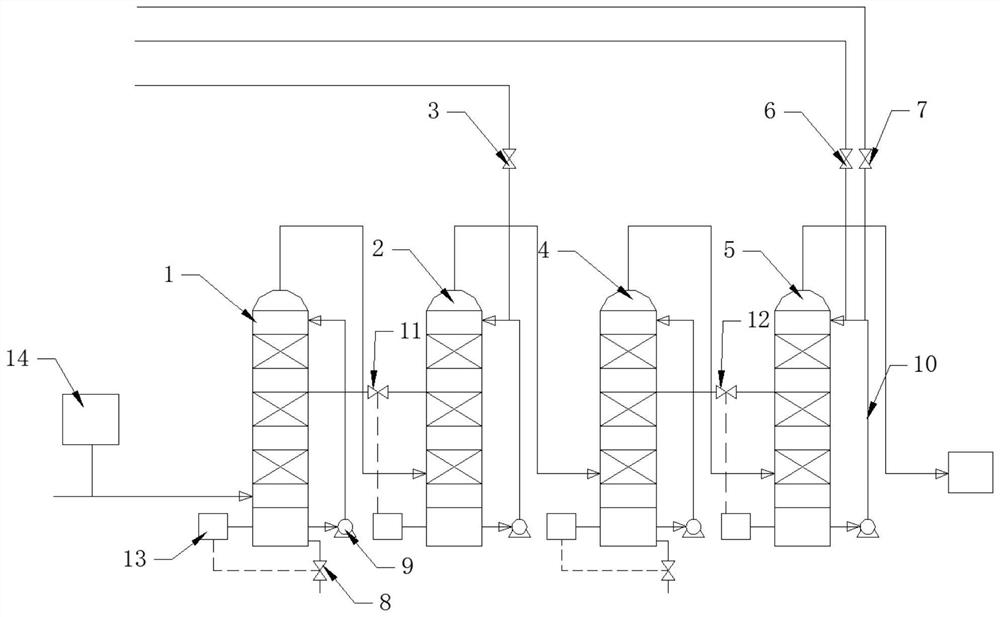

Four-tower normal-temperature nitrogen oxide removal process and four-tower normal-temperature nitrogen oxide removal device

A technology for removing nitrogen oxides, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of high operating costs and low effective utilization of chemicals, reduce travel factors and increase effective utilization , the effect of preventing pipe clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] As one of the preferred implementations, each component and parameters in the process are implemented as follows:

[0071] Intake components:

[0072] Intake volume is 3000Nm 3 / h, NO concentration is 285mg / m 3 , NO 2 The concentration is 108mg / m 3 ;

[0073] In the primary oxidation tower:

[0074] The pH value is 3.2, the oxidant concentration is 0.435%, and the temperature is 32.5°C, wherein the oxidant is sodium chlorite;

[0075] In the deep oxidation tower:

[0076] The pH value is 4.3, the oxidant concentration is 3.54%, and the temperature is 35.6°C, wherein the oxidant is sodium chlorite;

[0077] In the primary reduction tower:

[0078] The pH value is 11.6, the reducing agent concentration is 0.23%, and the temperature is 34.3°C;

[0079] In the deep reduction tower:

[0080] The pH value is 12.6, the reducing agent concentration is 2.56%, and the temperature is 35.9°C;

[0081] Outgassing components:

[0082] NO concentration is 1.34mg / m 3 , NO ...

Embodiment 2

[0084] As one of the preferred implementations, each component and parameters in the process are implemented as follows:

[0085] Intake components:

[0086] Intake volume is 5000Nm 3 / h, NO concentration is 155mg / m 3 , NO 2 The concentration is 80mg / m 3 ;

[0087] In the primary oxidation tower:

[0088] The pH value is 3.4, the oxidant concentration is 0.342%, and the temperature is 35.7°C, wherein the oxidant is sodium chlorite;

[0089] In the deep oxidation tower:

[0090] The pH value is 4.5, the oxidant concentration is 2.78%, and the temperature is 38.6°C, wherein the oxidant is sodium chlorite;

[0091] In the primary reduction tower:

[0092] The pH value is 11.7, the reducing agent concentration is 0.34%, and the temperature is 36.7°C;

[0093] In the deep reduction tower:

[0094] The pH value is 12.8, the reducing agent concentration is 2.36%, and the temperature is 37.7°C;

[0095] Outgassing components:

[0096] NO concentration is 1.17mg / m 3 , NO ...

Embodiment 3

[0098] As one of the preferred implementations, each component and parameters in the process are implemented as follows:

[0099] Intake components:

[0100] Intake volume is 8000Nm 3 / h, NO concentration is 320mg / m 3 , NO 2 The concentration is 126mg / m 3 ;

[0101] In the primary oxidation tower:

[0102] The pH value is 3.1, the oxidant concentration is 0.503%, and the temperature is 39.6°C, wherein the oxidant is sodium chlorite;

[0103] In the deep oxidation tower:

[0104] The pH value is 4.3, the oxidant concentration is 4.01%, and the temperature is 42.4°C, wherein the oxidant is sodium chlorite;

[0105] In the primary reduction tower:

[0106] The pH value is 11.3, the reducing agent concentration is 0.17%, and the temperature is 40.1°C;

[0107] In the deep reduction tower:

[0108] The pH value is 12.2, the reducing agent concentration is 1.87%, and the temperature is 41.5°C;

[0109] Outgassing components:

[0110] NO concentration is 3.23mg / m 3 , NO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com