Cooling system of transformer for reduction furnace and cooling method thereof

A technology of cooling system and cooling method, applied in the direction of transformer/inductor cooling, transformer/inductor parts, electrical component structure association, etc., can solve problems such as poor cooling effect of transformer, influence of polysilicon production efficiency, and burnout of transformer , to achieve good applicability and promotion, outstanding cooling effect, and the effect of preventing resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

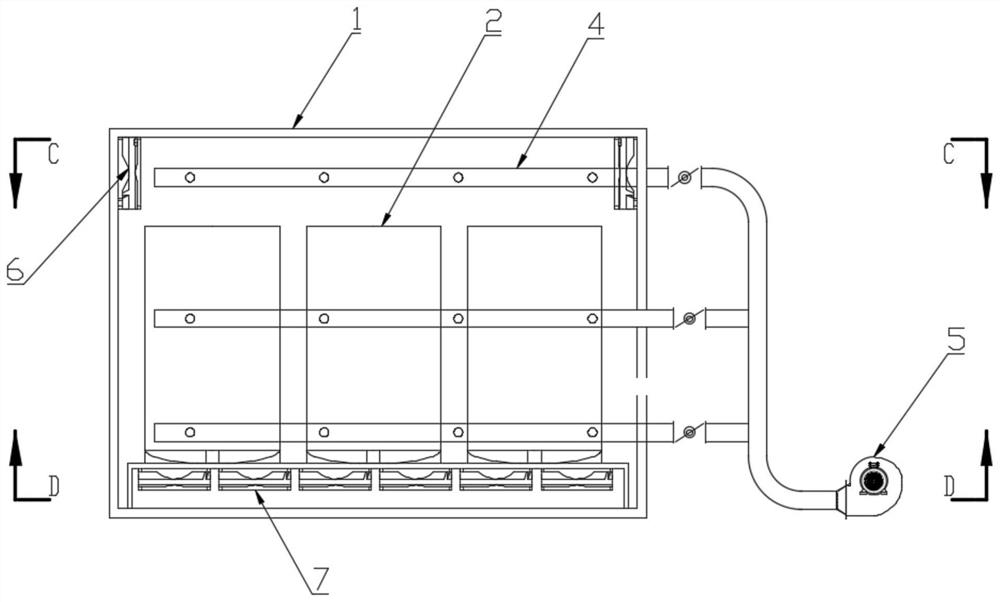

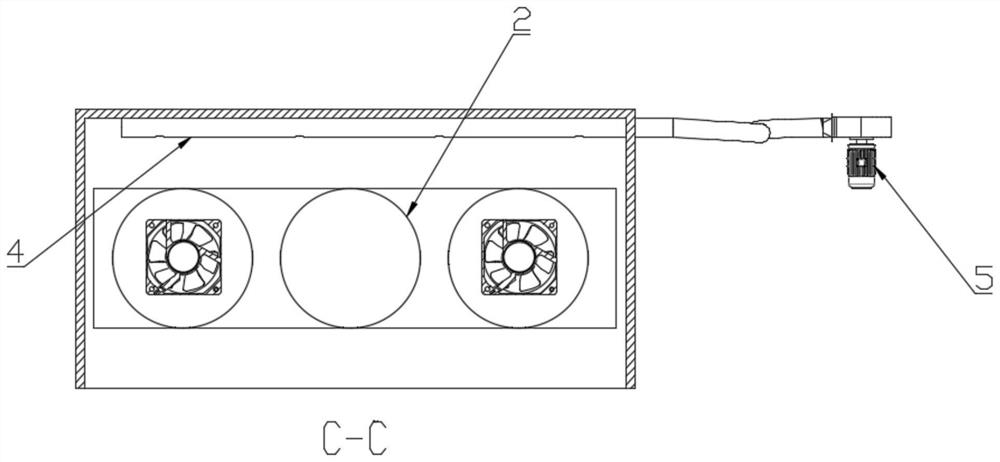

[0039] Such as figure 1As shown, in this embodiment, a cooling system for a transformer used in a reduction furnace is specifically provided to solve the problem of cooling the transformer 2 in the production of an existing polysilicon reduction furnace, which mainly includes a cooling box 1 that can be opened and closed on one side, For the design of the cooling box 1, the cooling box 1 is set as a rectangular box with one side opening, and the front side of the cooling box 1 is the opening side and this side is provided with an openable and closable airtight door. There are three transformers 2, and under the operation of each transformer 2, the power supply for the normal operation of the reduction furnace is realized. In actual application, the airtight door is not a whole, it includes a door frame and a plurality of door panels inside the door frame, each of the door panels is hingedly connected to the door frame and a locking member is provided between each door panel an...

Embodiment 2

[0046] On the basis of the cooling system provided in Embodiment 1, in this embodiment, a cooling method for a transformer used in a polysilicon reduction furnace is specifically provided, and the cooling method includes:

[0047] S1: Real-time monitoring of the temperature in the cooling box 1. In practical application, temperature monitors can be arranged at multiple points in the cooling box 1, and the maximum value of each temperature monitor can be taken as the temperature reference value of the cooling box 1.

[0048] S2: Adjust the opening degree of one side of the cooling box 1 by monitoring the outdoor temperature in real time. The adjustment logic is: divide the opening degree of one side of the cooling box 1 from small to large into four levels. The fourth level here refers to the opening degree in embodiment 1 The airtight door includes four door panels, opening one door panel is the first level of opening, opening two door panels is the second level of opening, and...

Embodiment 3

[0053] On the basis of the cooling system of the transformer used in the reduction furnace provided in Embodiment 1, in order to further optimize its maintainability during operation, as Figure 5 As shown, it is improved as follows:

[0054] A plurality of groups of slide rails 10 are arranged below the support frame, and each group of slide rails 10 is equipped with a suspension 8 slidably mounted on it respectively, and each suspension 8 is equipped with the cooling fan 7 respectively, and by pushing the suspension 8. The cooling fan 7 can be installed in a preset position. When the cooling fan 7 needs maintenance, the suspension 8 can be pulled to pull the cooling fan 7 out and cooperate with the staff for maintenance.

[0055] Each suspension 8 is provided with a limit block 11, and the limit block 11 is provided with a limit hole; a plurality of telescopic electromagnets 9 are arranged below the support frame, and the telescopic rod of the telescopic electromagnet 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com