Screen detection and screen detection model training method, device and equipment

A screen detection and screen technology, applied in the field of image processing, can solve the problems of difficult detection and low accuracy, and achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

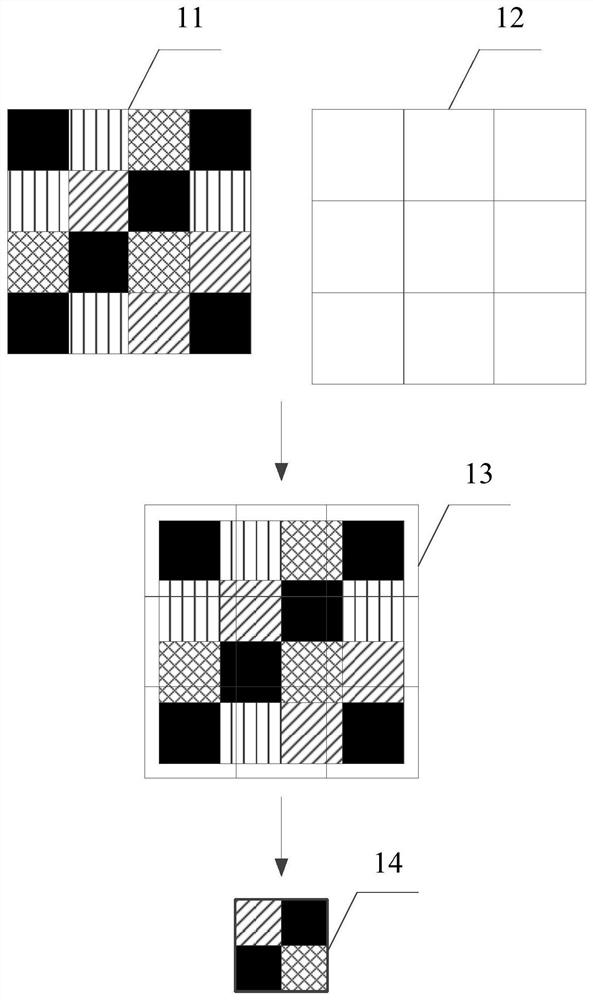

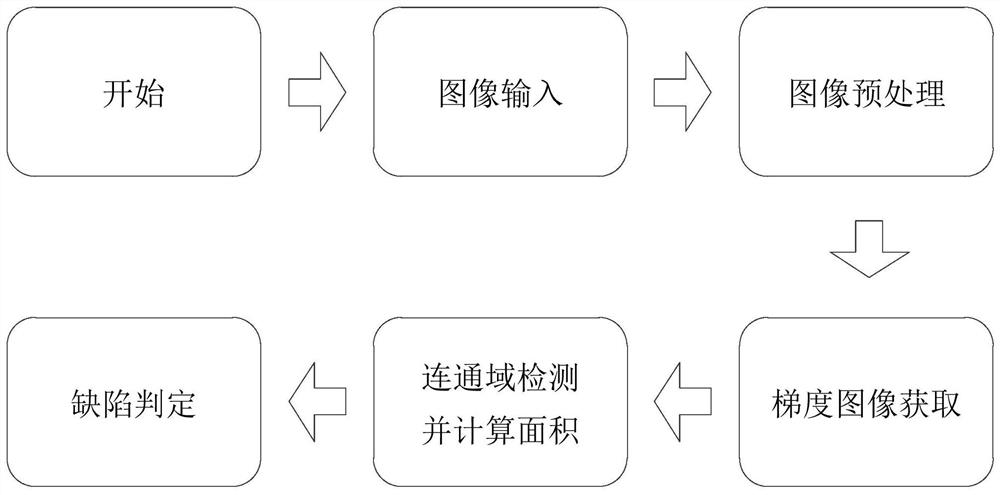

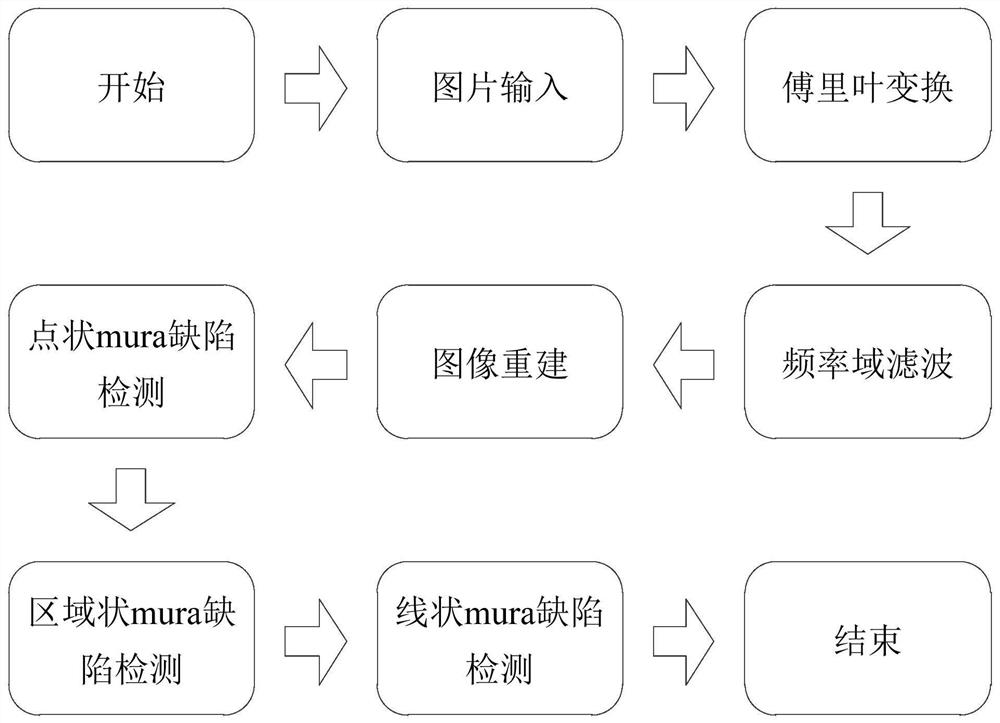

Method used

Image

Examples

Embodiment Construction

[0133] Firstly, the concepts involved in this application will be described.

[0134] TFT: Thin Film Transistor, thin film transistor.

[0135] LCD: Liquid Crystal Display, liquid crystal display, is an active matrix liquid crystal display driven by TFT.

[0136] OLED: Organic Light-Emitting Diode, organic light-emitting diode.

[0137] Screen Defect (Screen Defect): Display screens are usually composed of multiple materials and substrate layers bonded together, it is almost impossible to bond all these layers with absolute precision every time, various seams, migration , contaminants, air bubbles, or other imperfections may be introduced. For example, defects on LCDs may include: impurities or impurity particles in the liquid crystal matrix, uneven distribution of the LCD matrix during the manufacturing process, uneven TFT thickness, and Uneven spacing between them, uneven brightness distribution of the backlight source, flaws in the LCD panel, etc. All of the above factor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com