A black electrolytic coloring additive for aluminum profiles and its coloring process

An electrolyte additive and electrolytic coloring technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of single-tin salt coloring process instability, high cost, and low-thickness oxide film. , to achieve the effect of good black reproducibility, low cost of matching tanks and prolonging the coloring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

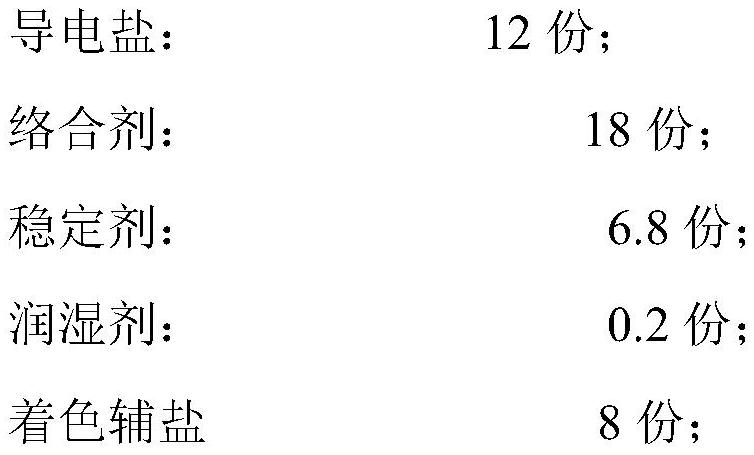

[0031] A black solid additive for aluminum alloy electrolysis, comprising the following components:

[0032]

[0033]

[0034] The conductive salt is magnesium sulfate heptahydrate, the complexing agent is tartaric acid, the stabilizing agent is sodium thiazoline dithiopropane sulfonate; the wetting agent is polyethylene glycol (M=6000~10000), the coloring Auxiliary salt is antimony potassium tartrate.

[0035] The process of electrolytic blackening includes the following steps:

[0036] (1) Pretreatment, immerse the aluminum alloy sample in a solution containing strong alkaline substances such as sodium hydroxide for alkaline etching treatment, remove the natural oxide film, and wash it with water.

[0037] (2) Anodic oxidation, the aluminum alloy sample that has been treated by alkali etching is immersed in a sulfuric acid solution prepared by concentrated sulfuric acid (98%) and pure water according to the mass ratio of 18:82 for anodic oxidation treatment. Oxidatio...

Embodiment 2

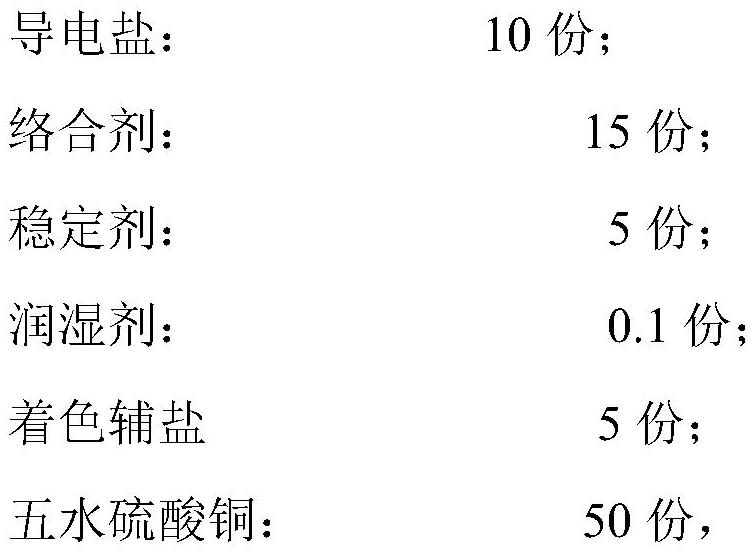

[0041] A black solid additive for aluminum alloy electrolysis, comprising the following components:

[0042]

[0043] The conductive salt is aluminum sulfate hexadecahydrate, the complexing agent is salicylic acid, the stabilizing agent is sodium polydithiodipropane sulfonate; the wetting agent is polyether, and the auxiliary coloring salt is antimony potassium tartrate.

[0044] The process of electrolytic blackening is the same as that of Example 1. Finally, under the condition that the anodic oxide film is 6-8 μm and the electrolytic coloring time is 10 minutes, a true black oxide film surface is obtained.

Embodiment 3

[0046] A black solid additive for aluminum alloy electrolysis, comprising the following components:

[0047]

[0048]

[0049] The conductive salt is magnesium acetate, the complexing agent is sodium citrate, the stabilizer is sodium polydithiodipropane sulfonate; the wetting agent is polyether, and the auxiliary coloring salt is antimony potassium tartrate.

[0050] The process of electrolytic blackening is the same as that of Example 1. Finally, under the condition that the anodic oxide film is 6-8 μm and the electrolytic coloring time is 10 minutes, a true black oxide film surface is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com