Green carbon steel corrosion inhibitor based on Bisflavanol

A corrosion inhibitor and carbon steel technology, applied in organic chemistry, organic chemistry methods, etc., can solve the problems of corrosion inhibitor side effects, environmental pollution, etc., and achieve the effect of inhibiting corrosion and excessive consumption, low dosage and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare solutions with concentrations of 0.2 mM, 0.4 mM, 0.6 mM, 0.8 Mm, and 1.0 mM with 0.5 mol / L dilute hydrochloric acid, respectively. Clean the carbon steel at room temperature, immerse it for 12 h, and then carry out the rotation test. At the same time, do a blank test without corrosion inhibitor. According to the formula: Calculate the corrosion inhibition efficiency, where is the corrosion rate without corrosion inhibitor, is the corrosion rate of corrosion inhibitor.

[0024] The test procedure should comply with the relevant provisions of HG / T 2159-91 Determination of Corrosion Inhibition Performance of Water Treatment Agents by Rotary Coupon Method.

Embodiment 2

[0026] Prepare solutions with concentrations of 0.2 mM, 0.4 mM, 0.6 mM, 0.8 Mm, and 1.0 mM with 1 mol / L dilute hydrochloric acid, respectively. Clean the carbon steel at room temperature, immerse it for 12 h, and then carry out the rotation test. At the same time, do a blank test without corrosion inhibitor. According to the formula: Calculate the corrosion inhibition efficiency, where is the corrosion rate without corrosion inhibitor, is the corrosion rate of corrosion inhibitor.

Embodiment 3

[0028] Prepare solutions with concentrations of 0.2 mM, 0.4 mM, 0.6 mM, 0.8 Mm, and 1.0 mM with 2 mol / L dilute hydrochloric acid, respectively. Clean the carbon steel at room temperature, immerse it for 12 h, and then carry out the rotation test. At the same time, do a blank test without corrosion inhibitor. According to the formula: Calculate the corrosion inhibition efficiency, where is the corrosion rate without corrosion inhibitor, is the corrosion rate of corrosion inhibitor.

[0029] The corrosion inhibition rate of the above three examples on carbon steel in acidic solution is as follows:

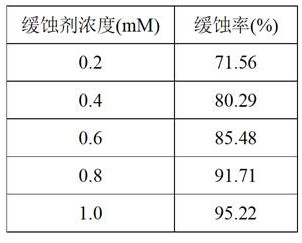

[0030] Table 1 Example 1

[0031]

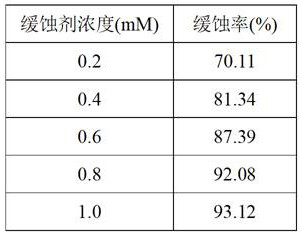

[0032] Table 2 Example 2

[0033]

[0034] Table 3 Example 3

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com