Vertical sand mill and sand making method

A sand mill, vertical technology, applied in the direction of grain processing, etc., can solve the problems that it is difficult to return to the roller table for grinding, accumulate on the outer periphery of the grinding table, and affect the passage of materials, so as to reduce the number of rolling times, improve the crushing ratio, and increase the passage. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better explain the content of the present invention, the technical solutions of the present invention will be described below in conjunction with the drawings and through specific implementation methods.

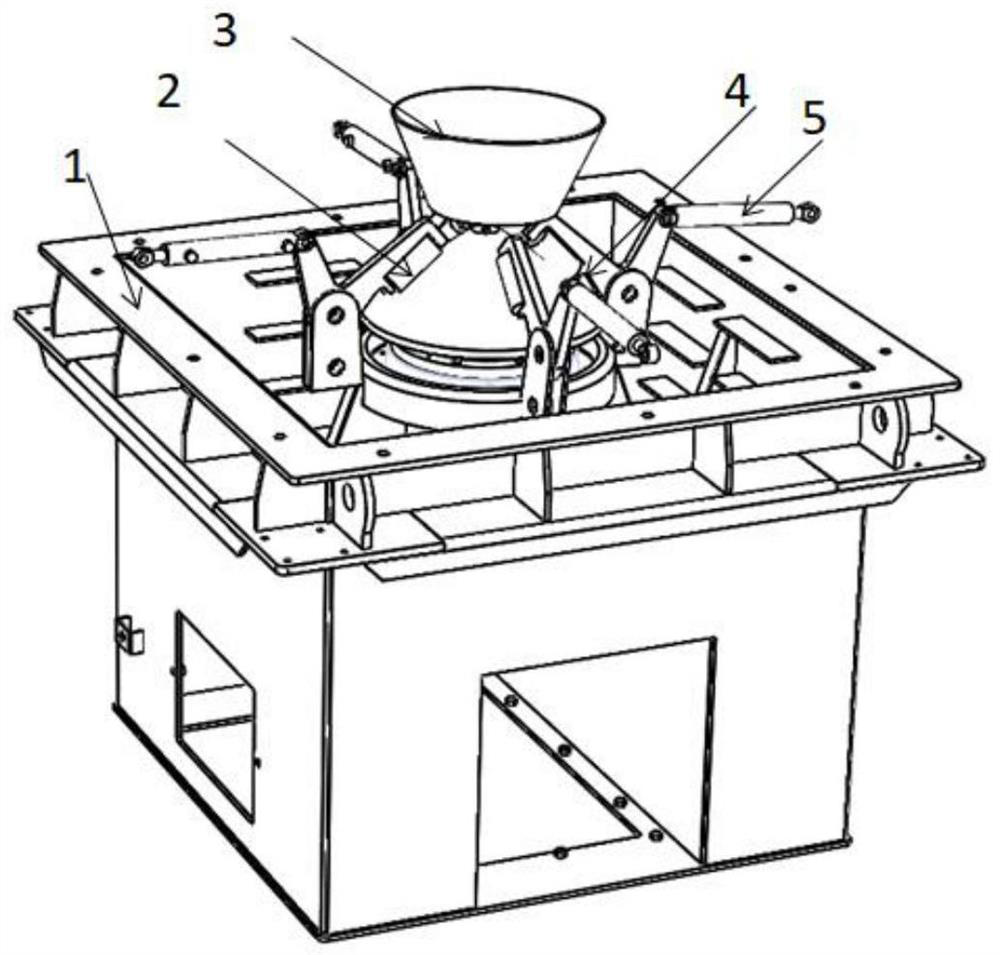

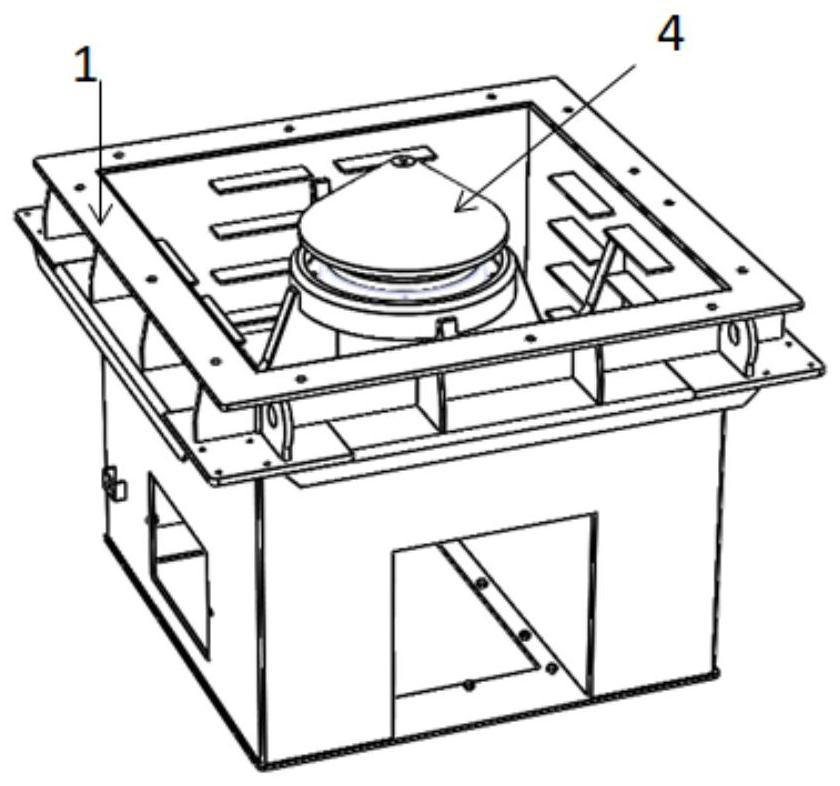

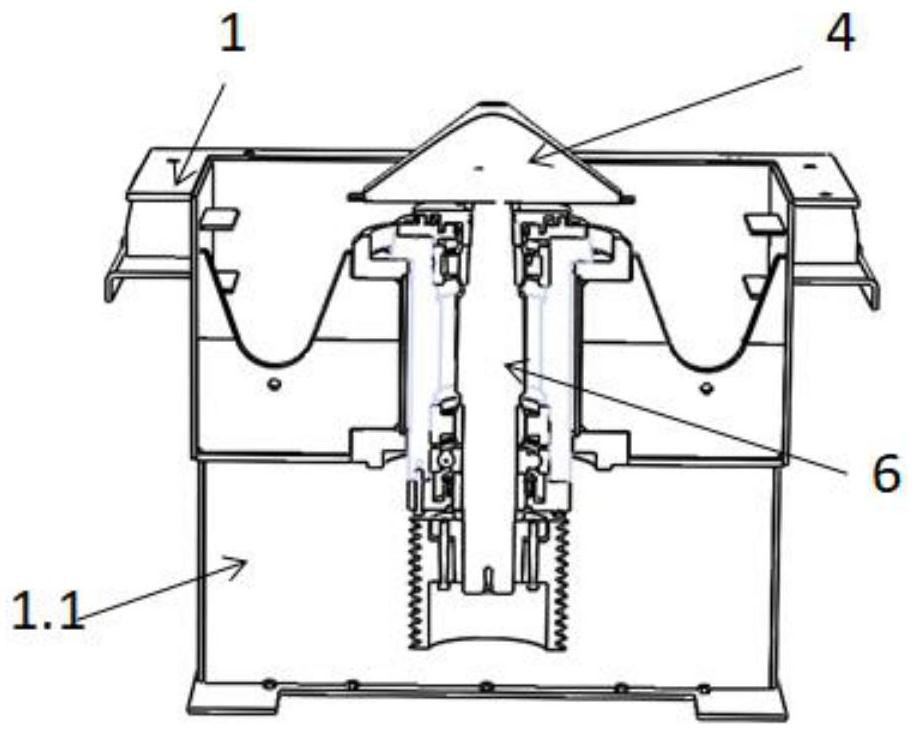

[0034] figure 1 It is a schematic diagram of the first embodiment of the sand mill. In the figure, the vertical sand mill includes a central vertical conical turntable 4 and several disc rollers 2 installed above the conical turntable 4. There is a certain gap between the disc rollers 2 and the conical turntable 4, and installation The sand grinding cover (for convenience of showing the internal structure, the sand grinding cover is not shown in the figure) at the periphery of the conical turntable 4 and the millstone roller 2 forms a grinding cavity between the sand grinding cover and the conical turntable. The frame 1 provides the base and support of the whole machine. The conical turntable 4 is located at the upper center of the lower part 1. The four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com