Infinitesimal-based conductor temperature calculation method for cable joint and body

A technology for the temperature of cable joints and conductors is applied in the field of conductor temperature calculation of cable joints and bodies, and can solve the problems of difficult to guarantee the accuracy of temperature monitoring results, complex modeling process, and low calculation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example ;

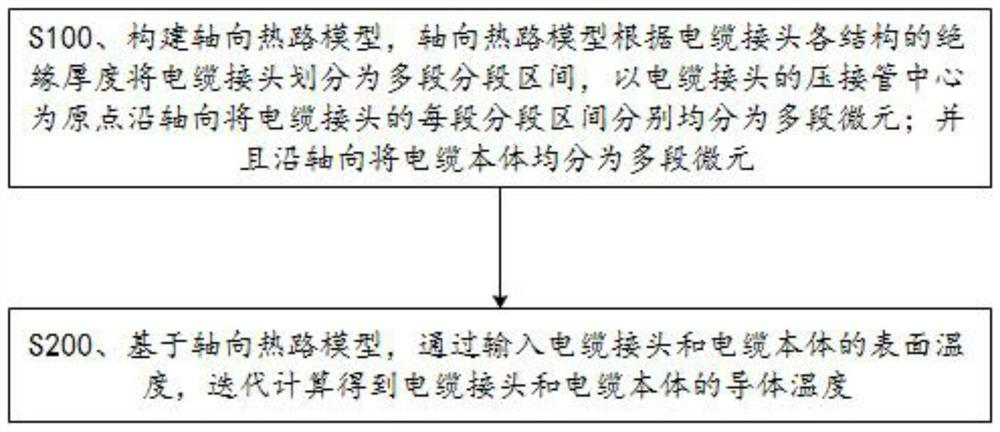

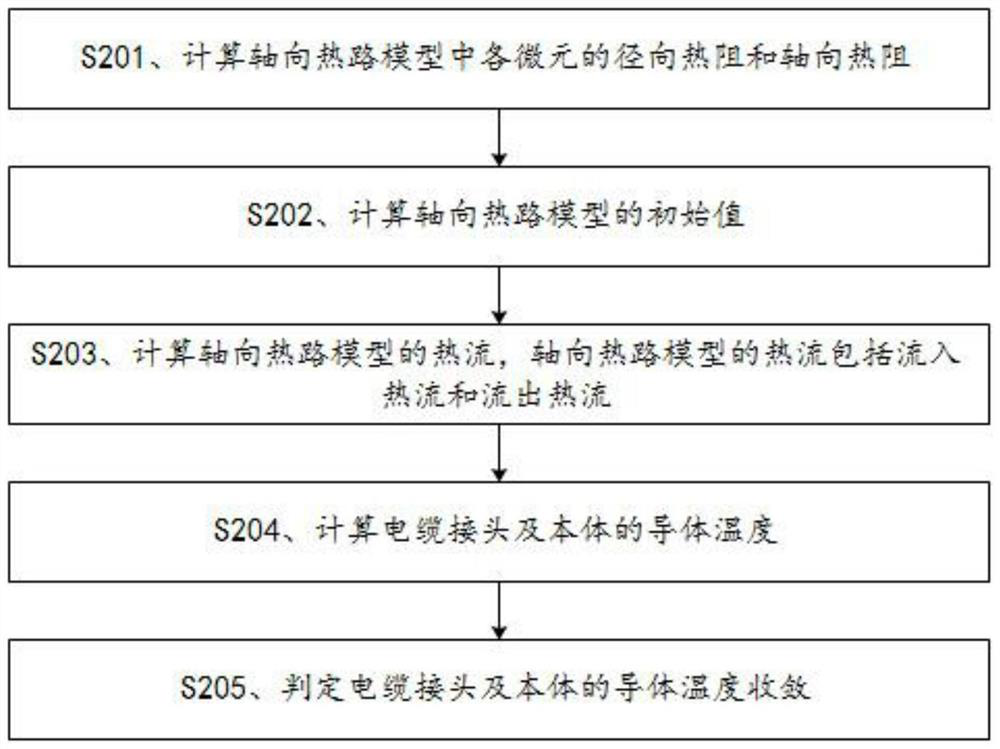

[0026] refer to Figure 1 to Figure 3 , an embodiment of the present invention provides a method for calculating the conductor temperature of a cable joint and a body based on microelements, which is used to calculate the conductor temperature of the cable joint and the cable body adjacent to the cable joint, comprising the following steps:

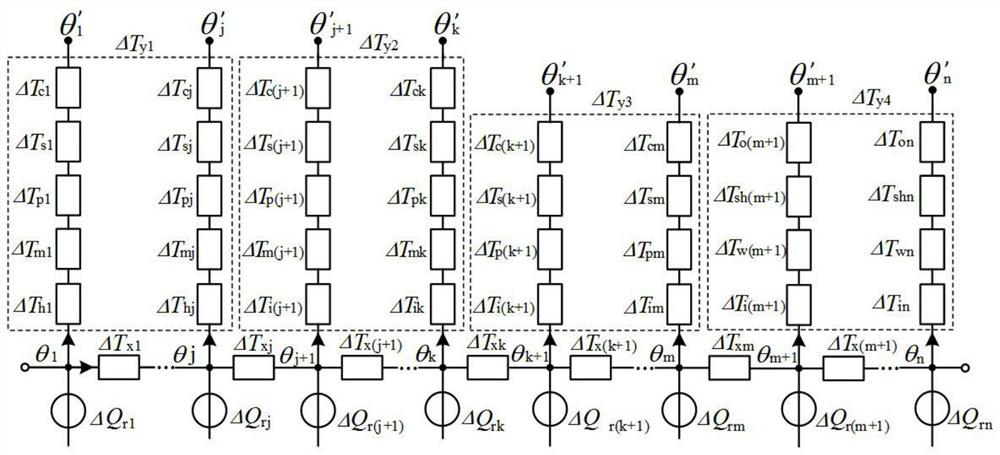

[0027] S100. Construct an axial thermal circuit model. The axial thermal circuit model divides the cable joint into multiple sections according to the insulation thickness of each structure of the cable joint, and takes the center of the crimping tube of the cable joint as the origin to divide each section of the cable joint in the axial direction. The segmented intervals are respectively divided into multi-segment micro-units; and the cable body is divided into multi-segment micro-units along the axial direction.

[0028] It should be noted that since the structure of the cable joint is axisymmetric, and the structure of the long end is ...

no. 2 example ;

[0080] In order to verify the effect of the embodiments of the present invention, a set of experimental data is provided below:

[0081] To adapt to 110kV 630mm 2 For the straight-through joint of the cable, the carrying capacity of the line is 1000A as an example. The axial thermal circuit model proposed in the embodiment of the method is used to calculate the conductor temperature. The theoretical calculation results and the simulation calculation results, as well as the joint temperature calculation proposed by the Egyptian scholar M.M.Abdel The results of the method are compared, the results are as follows Figure 4 shown. In the experiment, the distance of each micro-element is as follows:

[0082] Short-end crimping tube, short-end main insulation, short-end copper shell thin layer, short-end body micro-element lengths are 0.098m, 0.071m, 0.075m, 0.1257m respectively; long-end crimping tube, long-end main insulation, long-end The microelement lengths of the copper she...

no. 3 example ;

[0085] refer to Figure 5 , an embodiment of the present invention provides a conductor temperature calculation device based on a micro-element cable joint and a body, the conductor temperature calculation device based on a micro-element cable joint and a body can be any type of intelligent terminal, such as a mobile phone , Tablet PC, PC, etc.

[0086] Specifically, the microelement-based cable joint and conductor temperature calculation device of the body includes: one or more control processors and memory. The control processor and memory can be connected by bus or other means.

[0087] As a non-transitory computer-readable storage medium, the memory can be used to store non-transitory software programs, non-transitory computer executable programs and modules, such as the microelement-based cable connector and the conductor of the body in the embodiment of the present invention The program instruction / module corresponding to the temperature calculation device. The contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com