Formwork device of mirror-surface bare concrete beam column and construction method of formwork device

A fair-faced concrete and formwork technology, which is applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connecting parts, columns, etc., can solve the problem of low stability of mirror-faced fair-faced concrete beams and columns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-4 The application is described in further detail.

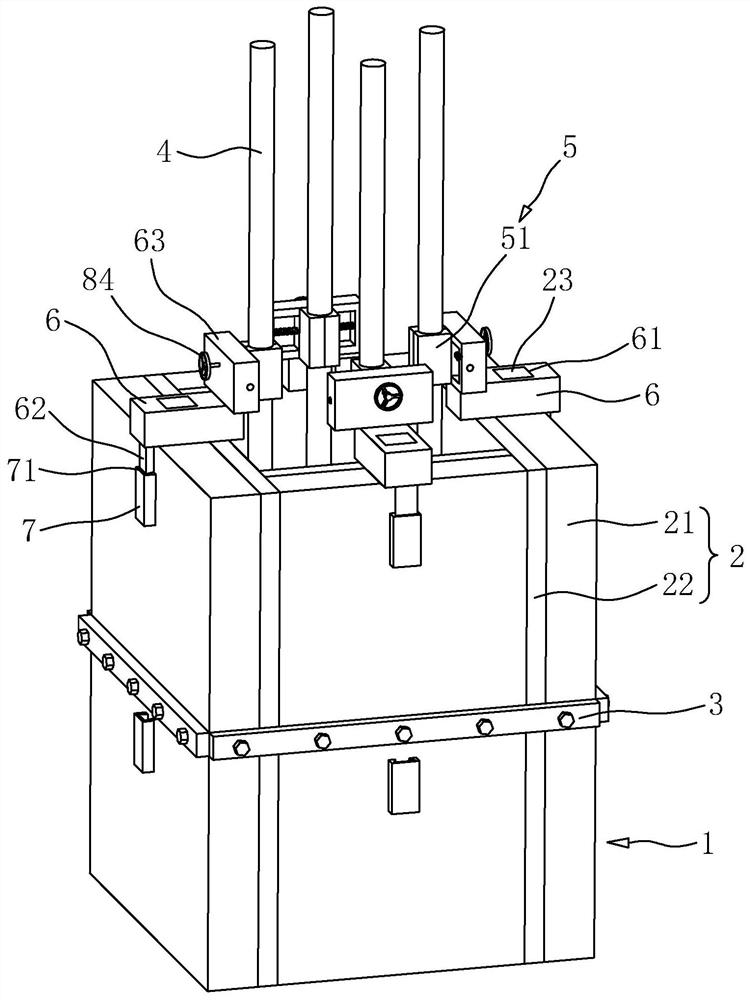

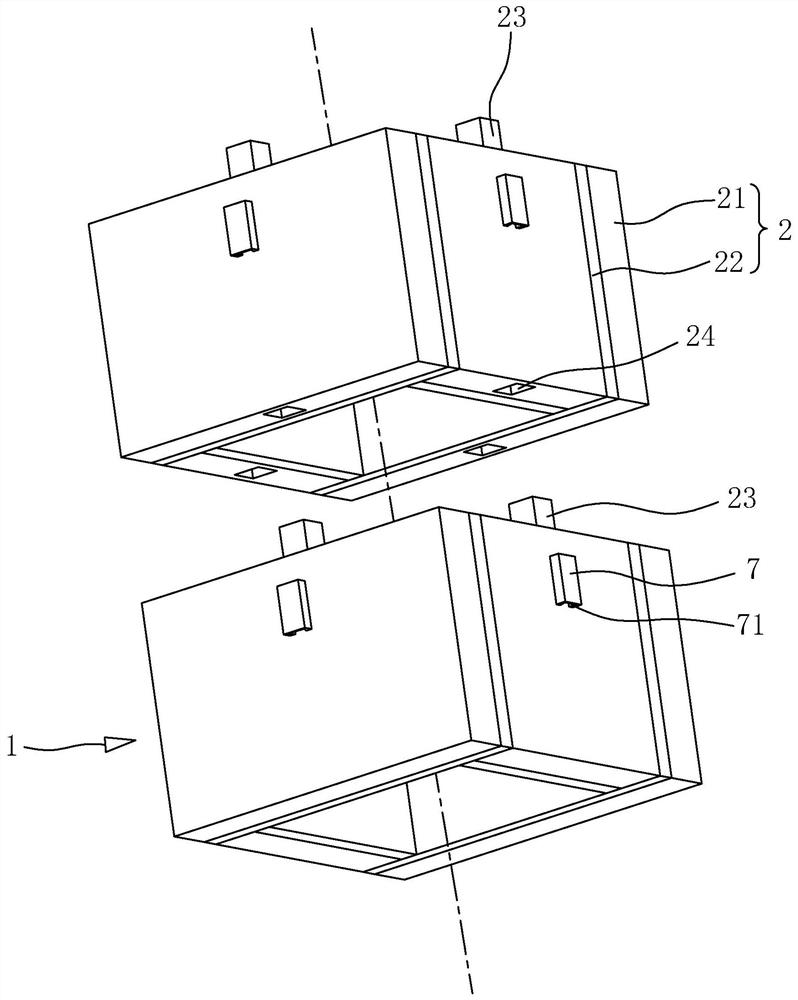

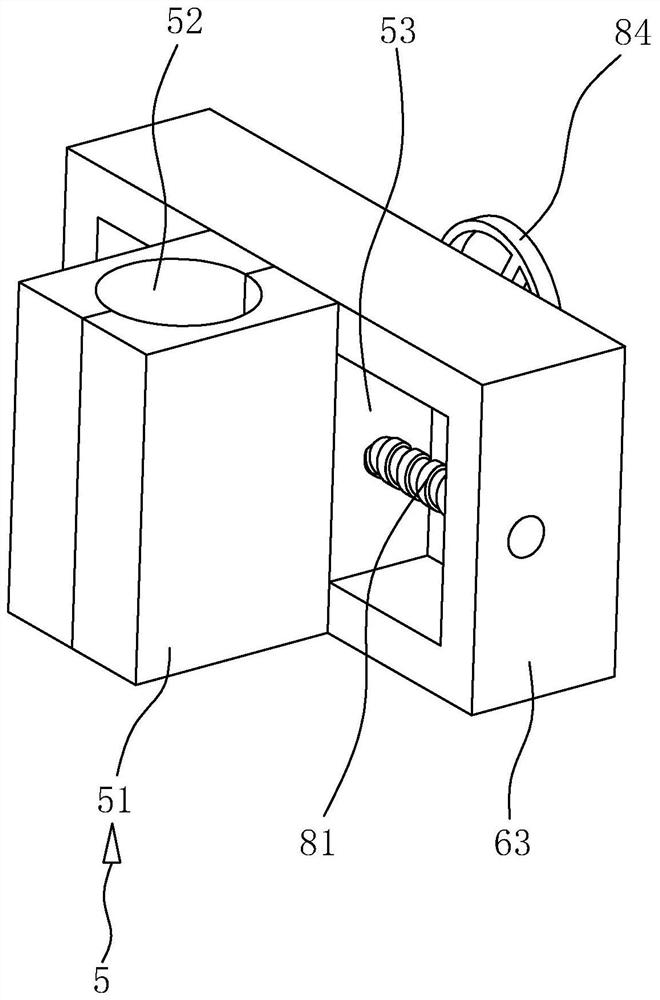

[0044] The embodiment of the present application discloses a formwork device for mirror-faced fair-faced concrete beams and columns. refer to figure 1 The formwork device of the mirror-faced concrete beam and column includes a formwork assembly 1, the formwork assembly 1 includes four formwork units 2, the formwork unit 2 includes an outer formwork 21, an inner formwork 22, the outer formwork 21 is a wooden board, and the inner formwork 22 is a PC board. Both the outer formwork 21 and the inner formwork 22 are arranged vertically, and the inner formwork 22 is glued to the inner side of the outer formwork 21 . The inner side of the PC board is a smooth surface, so that after the mirror clear-faced concrete is solidified, the outer surface can maintain a high degree of smoothness.

[0045] refer to figure 1, the four formwork units 2 are connected sequentially to form a square shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com