Ultralow-carbon high-strength high-plasticity martensitic steel and preparation method thereof

A martensitic steel, high-strength technology, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of steel strength limitation, welding performance and easy processing performance hazards, etc., to improve strength and plasticity, and a wide range of applications , the effect of good weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

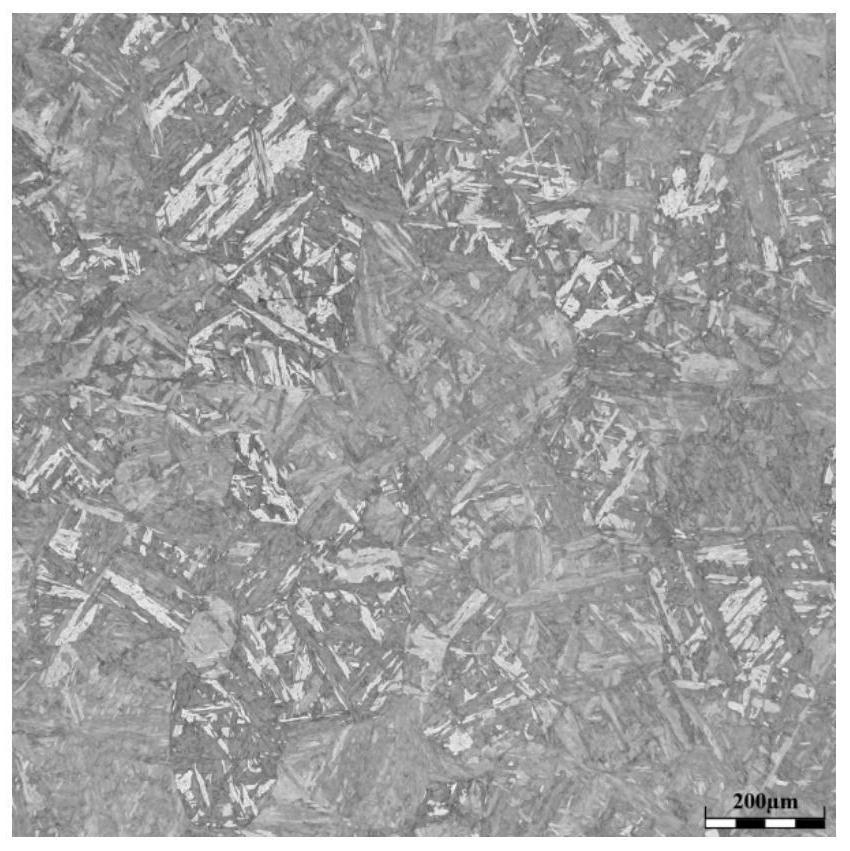

[0037] An ultra-low-carbon high-strength high-plasticity martensitic steel, the chemical composition mass percentage of the martensitic steel is: C: 0.05%, Si: 0.25%, Mn: 0.58%, Cr: 1.10%, Cu: 2.4%, Ni: 10.36%, V: 0.13%, Mo: 0.78%, Al: 0.41%, P: ≤0.02%, S: ≤0.02%, and the balance is Fe;

[0038] The microstructure of the martensitic steel is lath block martensite;

[0039] The preparation method of the above-mentioned a kind of ultra-low carbon high-strength high-plasticity martensitic steel comprises the following steps:

[0040] Step 1: According to the chemical composition ratio of martensitic steel, first add metal nickel plate, industrial pure iron, metal molybdenum, and metal chromium into the smelting furnace in turn, and smelt at 1490°C until the charge is fully melted, and then add industrial steel in turn. Silicon, metal manganese, copper, aluminum, vanadium iron, graphite, continue to smelt until the charge is fully melted, and finally cast into steel ingots;

[0...

Embodiment 2

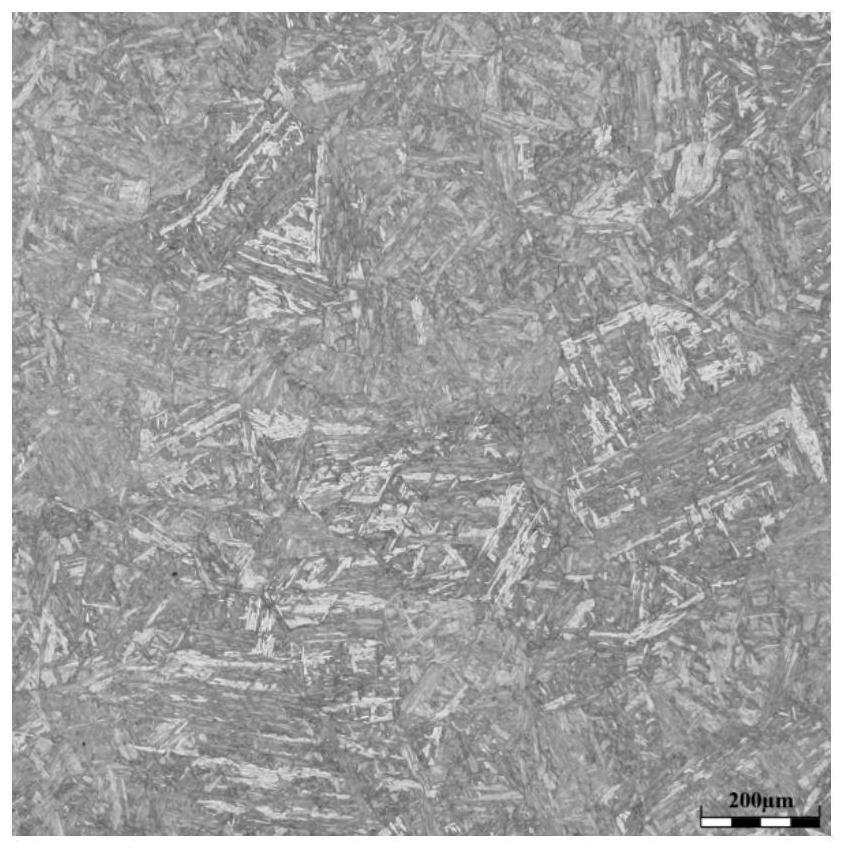

[0053] An ultra-low-carbon high-strength high-plasticity martensitic steel, the chemical composition mass percentage of the martensitic steel is: C: 0.04%, Si: 0.27%, Mn: 0.60%, Cr: 1.00%, Cu: 2.25%, Ni: 10.26%, V: 0.14%, Mo: 0.80%, Al: 0.40%, P: ≤0.02%, S: ≤0.02%, and the balance is Fe;

[0054] The microstructure of the martensitic steel is lath block martensite;

[0055] The preparation method of the above-mentioned a kind of ultra-low carbon high-strength high-plasticity martensitic steel comprises the following steps:

[0056] Step 1: According to the chemical composition ratio of martensitic steel, first add metal nickel plate, industrial pure iron, metal molybdenum, and metal chromium into the smelting furnace in turn, melt at 1500 ° C until the charge is fully melted, and then add industrial Silicon, metal manganese, copper, aluminum, vanadium iron, graphite, continue to smelt until the charge is fully melted, and finally cast into steel ingots;

[0057] The industri...

Embodiment 3

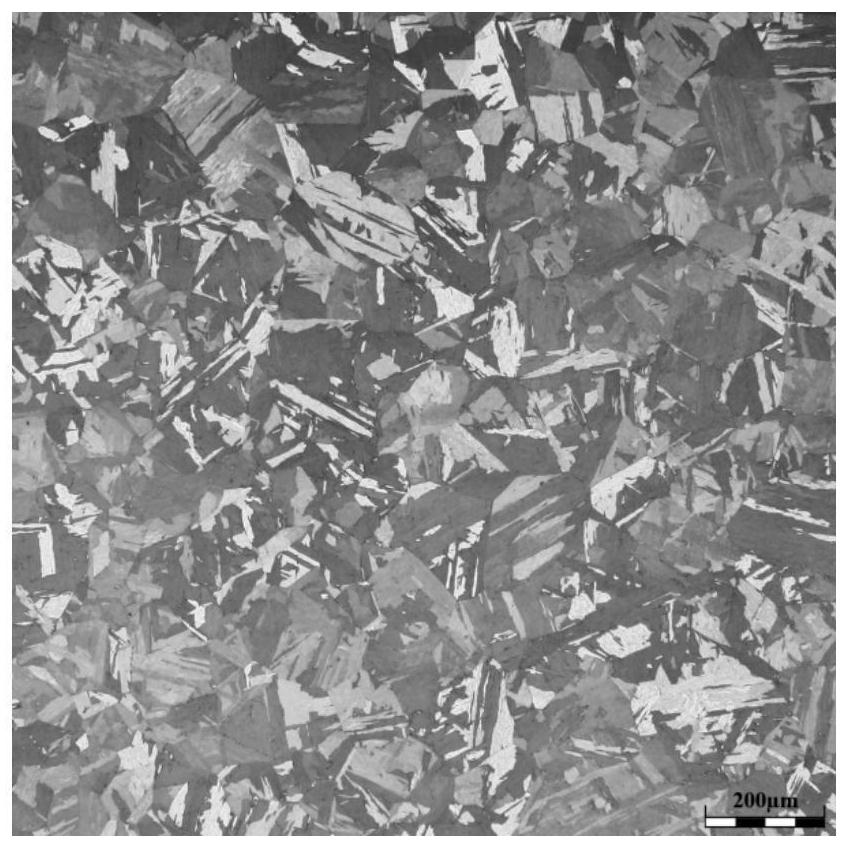

[0069] An ultra-low-carbon high-strength high-plasticity martensitic steel, the chemical composition mass percentage of the martensitic steel is: C: 0.02%, Si: 0.24%, Mn: 0.57%, Cr: 1.11%, Cu: 3.47%, Ni: 10.33%, V: 0.12%, Mo: 0.77%, Al: 0.42%, P: ≤0.02%, S: ≤0.02%, and the balance is Fe;

[0070] The microstructure of the martensitic steel is lath block martensite;

[0071] The preparation method of the above-mentioned a kind of ultra-low carbon high-strength high-plasticity martensitic steel comprises the following steps:

[0072] Step 1: According to the chemical composition ratio of martensitic steel, first add metal nickel plate, industrial pure iron, metal molybdenum, and metal chromium into the smelting furnace in turn, and smelt at 1490°C until the charge is fully melted, and then add industrial steel in turn. Silicon, metal manganese, copper, aluminum, vanadium iron, graphite, continue to smelt until the charge is fully melted, and finally cast into steel ingots;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com