Method for improving quality of waste vinasse of Luzhou-flavor liquor by utilizing clostridium

A technology of Clostridium and Luzhou-flavor liquor, applied in the field of winemaking, can solve the problems of low wine quality, low yield of discarded lees, mixed taste and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 prepares clostridium bacterial liquid

[0027] Inoculate a single colony of Clostridium in a 100mL anaerobic bottle containing RCM medium with a liquid filling volume of 90%, put it in an anaerobic box, and culture it statically at 37°C for 15-30 days to make the cell concentration reach 10 9 ~10 11 CFU / mL.

[0028] The above bacterial solution was inoculated into a 500mL anaerobic bottle containing RCM medium according to the inoculum amount of 10%, and the liquid filling volume was 90%, and placed in an anaerobic box, and cultured at 37°C for 15 to 30 days to make the bacteria Concentration up to 10 9 ~10 11 CFU / mL.

Embodiment 2

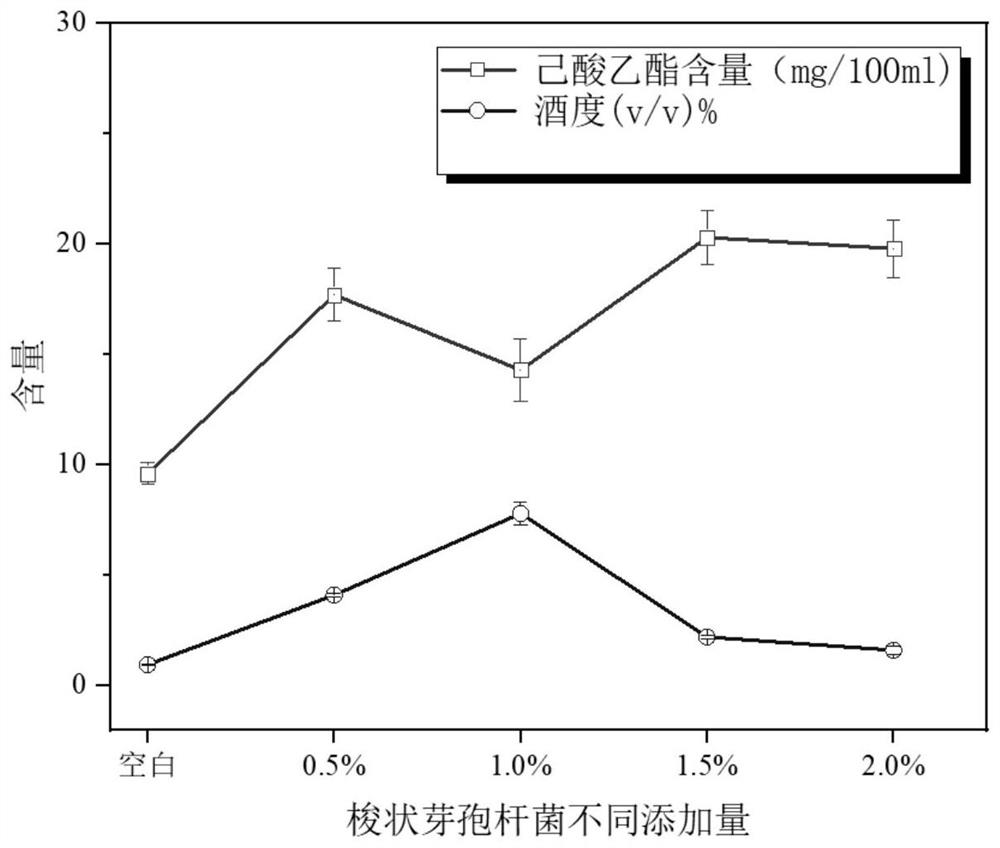

[0029] Example 2 Adding 0.5% Clostridium bacteria liquid to produce distilled grains

[0030] Take 5kg of distilled grains, add 0.5% of the cultured bacteria liquid, 0.7‰ of active dry yeast, and 0.8‰ of 100,000 units of glucoamylase, mix well, put them in barrels and carry out fermentation for 50 days to obtain distilled distilled grains wine; the blank group only adds cold boiled water 0.5%, 0.7‰ of active dry yeast, 0.8‰ of 100,000 units of glucoamylase, mixed evenly, put into barrels and ferment for 50 days to obtain distilled distilled grains wine; two experiments in each group were parallel. Results Compared with the blank control group, the content of ethyl caproate in the test group increased by 83.8%, and the alcohol content increased by 331.6%.

Embodiment 3

[0031] Example 3 Adding 1.0% Clostridium bacteria liquid to produce distilled grains

[0032] Take 5kg of distilled grains, add 1.0% of the cultured bacteria liquid, 0.7‰ of active dry yeast, 0.8‰ of 100,000 units of glucoamylase, mix well, put it into barrels and carry out fermentation for 50 days to obtain distilled distilled grains wine; the blank group only adds cold boiled water 1.0%, 0.4‰ of active dry yeast, 0.6‰ of 100,000 units of glucoamylase, mixed evenly, put into barrels and ferment for 50 days to obtain distilled distilled grains wine; two experiments in each group were parallel. Results Compared with the blank control group, the content of ethyl caproate in the test group increased by 49%, and the alcohol content increased by 721.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com