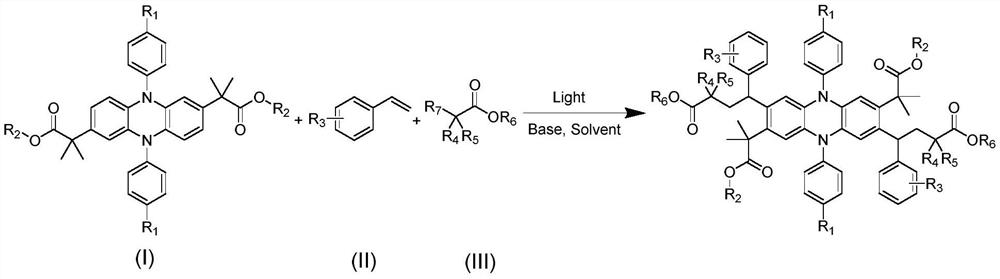

A kind of method of light-adjusting diaryldihydrophenazine modification

A technology of diaryldihydrophenazine and light regulation, applied in the direction of organic chemistry and the like, can solve the problems of many reaction steps, low yield, low final product yield, etc., and achieve the effect of high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

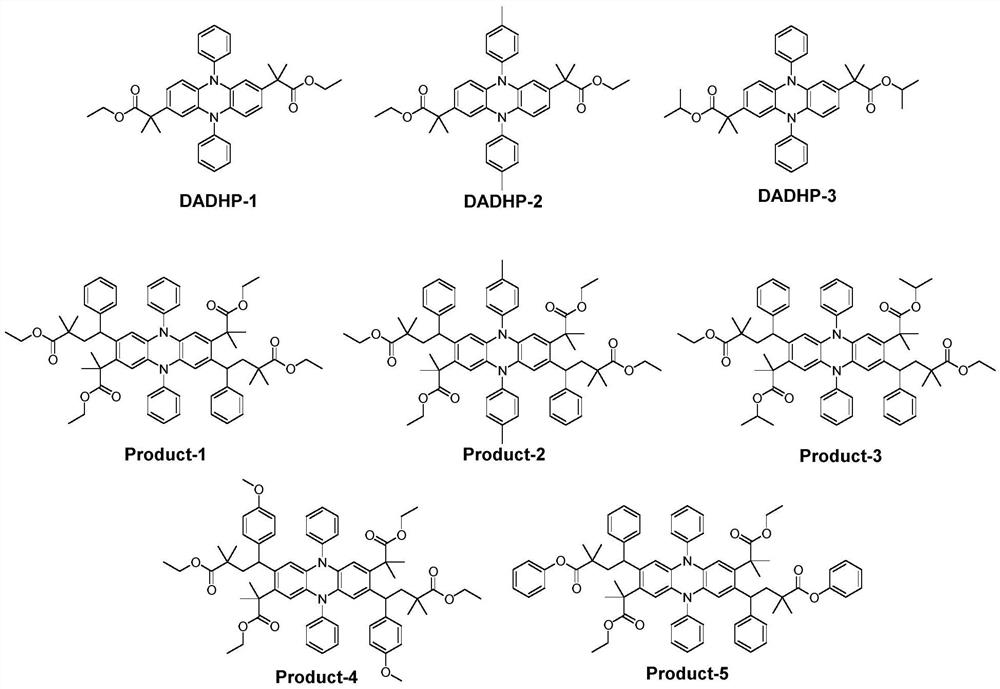

Embodiment 1

[0028] Example 1: At room temperature, into a 20mL transparent glass sample bottle were sequentially added polytetrafluoroethylene magnetic stirring bar, DHDAP-1 (50mg, 0.0889mmol, 1eq), styrene (93mg, 0.8892mmol, 10eq), 2-bromo - Ethyl 2-methylpropionate (347mg, 1.7785mmol, 20eq), sodium carbonate (20mg, 0.1778mmol, 2eq), 1,4-dioxane (5mL), plugged with a rubber stopper and sealed, replaced Air in the bottle and flush with nitrogen. Then, the reaction flask was placed under light (420-430 nm) conditions, and the reaction was performed for 24 h. Separation by column chromatography gave the product Product-1 (pale yellow solid, 79 mg, conversion 89%).

Embodiment 2

[0029] Example 2: At room temperature, into a 20mL transparent glass sample bottle were sequentially added polytetrafluoroethylene magnetic stirring bar, DHDAP-2 (50mg, 0.0847mmol, 1eq), styrene (88mg, 0.847mmol, 10eq), 2-bromo - Ethyl 2-methylpropionate (330mg, 1.694mmol, 20eq), sodium carbonate (18mg, 0.1694mmol, 2eq), 1,4-dioxane (5 mL), plug with rubber stopper and seal, replace Air out of the bottle and flushed with nitrogen. The reaction flask was then placed under light (420-430 nm) conditions for 24 hours of reaction. Separation by column chromatography gave the product Product-2 (pale yellow solid, 75 mg, 86% conversion).

Embodiment 3

[0030] Example 3: At room temperature, into a 20mL transparent glass sample bottle were sequentially added polytetrafluoroethylene magnetic stirring bar, DHDAP-3 (50mg, 0.0847mmol, 1eq), styrene (88mg, 0.847mmol, 10eq), 2-bromo - Ethyl 2-methylpropionate (330mg, 1.694mmol, 20eq), sodium carbonate (18mg, 0.1694mmol, 2eq), 1,4-dioxane (5 mL), plug with rubber stopper and seal, replace Air out of the bottle and flushed with nitrogen. The reaction flask was then placed under light (420-430 nm) conditions for 24 hours of reaction. Separation by column chromatography gave the product Product-3 (pale yellow solid, 82 mg, 94% conversion).

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com