Optimal blanking method of chip test automatic production line

An automated production line and chip testing technology, applied in automated testing systems, electronic circuit testing, electrical measurement, etc., can solve problems such as occupying machine space, increasing machine size, and increasing design costs, so as to improve timeliness and design The effect of reducing cost and improving the timeliness of blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are as follows.

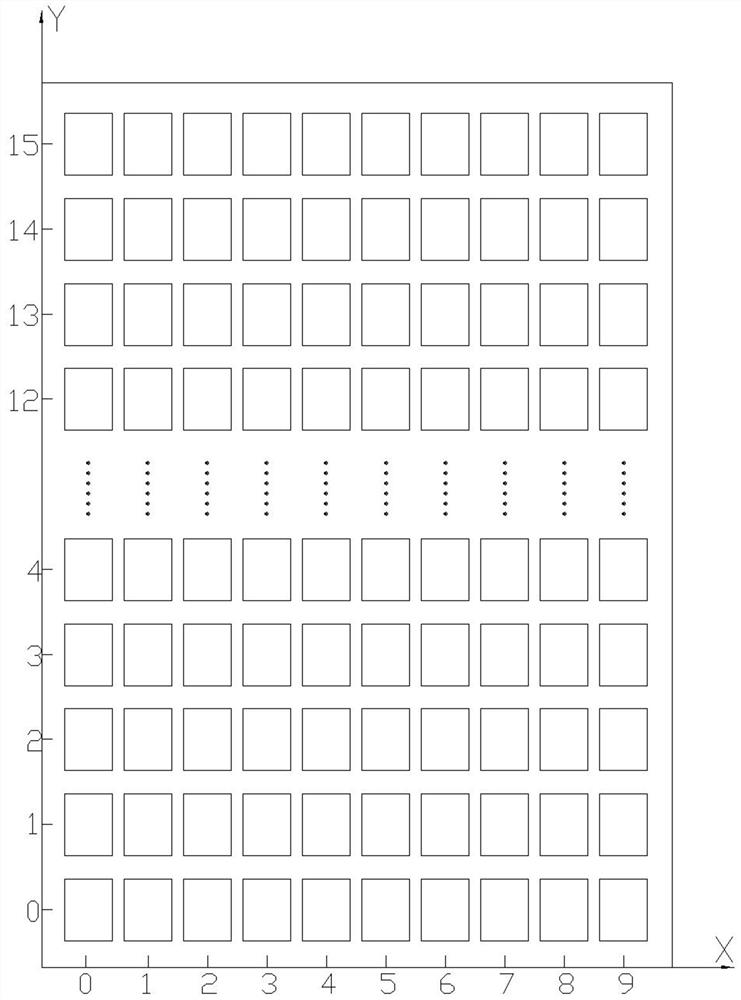

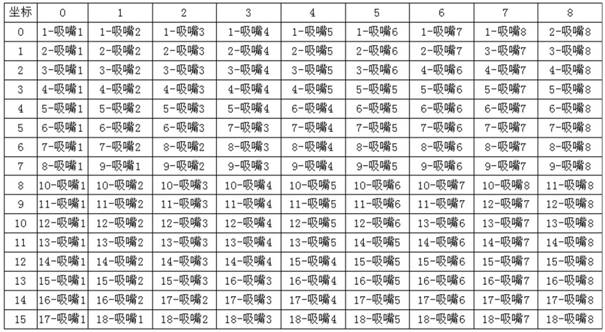

[0019] Such as figure 1 As shown, in the method of the present invention, the blanking equipment of the automatic chip test production line is set as a tray, the tray is provided with vertically and horizontally distributed chip positioning grooves, and the coordinate system is established with the vertically and horizontally distributed pallets of the chip positioning grooves, and the horizontal setting of the pallet is The X-axis is set as the Y-axis in the longitudinal direction of the tray, and the chip positioning slots provided on the tray have m rows×n columns, wherein m and n are both natural numbers greater than 1, and m>n, each chip positioning slot is set Set it as a coordinate point, set the chip positioning groove in the first row and the first column as the origin of the coordinate system, the coordinate value is (X, Y) = (0,0), the coordinates of the chip positioning groove in the first row and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com