A mobile stacking dense storage warehouse

A storage and stacking technology, applied in the field of three-dimensional warehouse, can solve the problems of slow loading and unloading of goods, taking a long time, complex fork structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the examples do not constitute a limitation to the present invention.

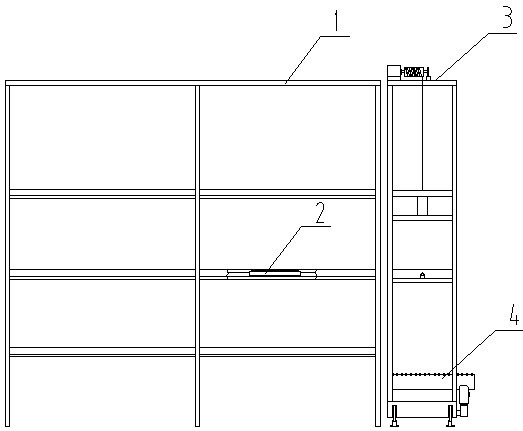

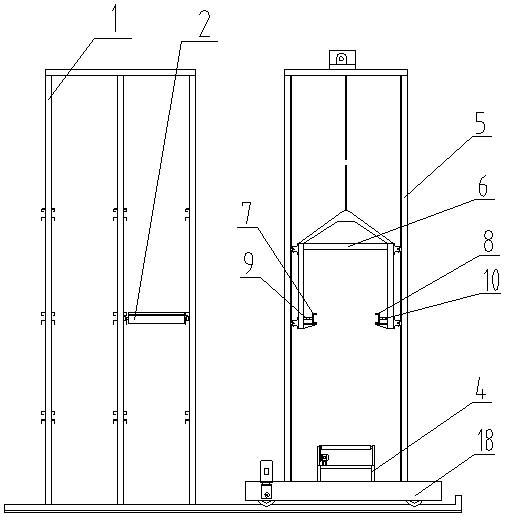

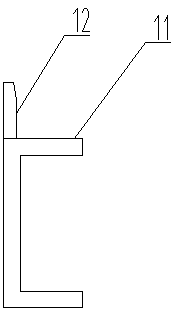

[0019] figure 1 , figure 2 with image 3 It shows the first embodiment of a mobile stacking dense storage warehouse of the present invention, which includes two rows of three-layer penetrating storage shelves 1, a shuttle car 2 passing through the guide rails of the shelves 1, and a mobile face at the end of the shelf 1. The roadway stacker 3 and the roller conveyor 4 for the operation of each row of shelves, the roadway stacker 3 includes a traveling trolley 18, a frame 5 vertically installed on the traveling trolley 18 and a lifting platform that lifts along the frame 5 6. The shuttle car guide rail 7 is installed on the left side of the lifting platform 6, and the shuttle car guide rail 8 is installed on the right side. The upper part of the shuttle car guide rail is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com