Oblique pressing ball type movable plier mechanism of flat tongs

A technology of flat-nose tongs and movable tongs, applied in the field of oblique ball-type movable tongs, can solve the problems of poor processing technology, scrapping, inability to accurately locate and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

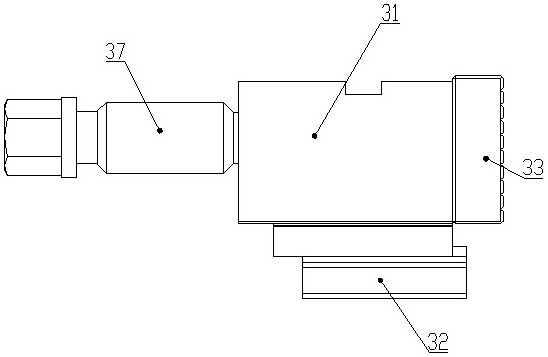

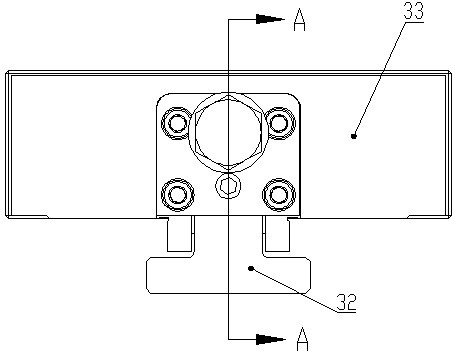

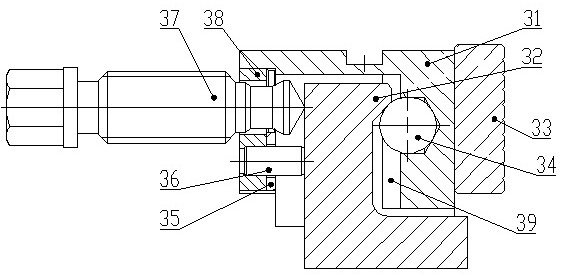

[0013] Such as Figure 1 to Figure 5 As shown, the movable pliers 3 of this embodiment includes a movable pliers body 31, an L-shaped oblique pressure block 32 with an inner bayonet, a jaw 33, a steel ball 34, a screw rod 37, a baffle plate 38, a clamping plate 35 and a set screw 36. The slide rail on the lower end surface of the movable pliers body 31 is slidably clamped and fixed on the upper end surface of the flat-nose pliers body 1, the front end surface is fixed with a jaw 33, and an oblique block mounting groove is left in the middle, and a clamp plate 35 is fixed at the rear end. , The rear end of the clamping plate 35 is fixed with a baffle plate 38 . The screw mandrel 37 is threadedly connected in the threaded hole I of the support 2 of the vise, and after its front end passes through the through hole of the baffle plate 38, its hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com