Pile foundation flexible connection joint only used for pulling resistance and construction method

A flexible technology for connecting nodes and pile foundations. It is used in infrastructure engineering, construction, protection devices, etc. It can solve the problems of increased reinforcement, excessive deformation, and increased thickness of raft foundations, reducing internal force and reinforcement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

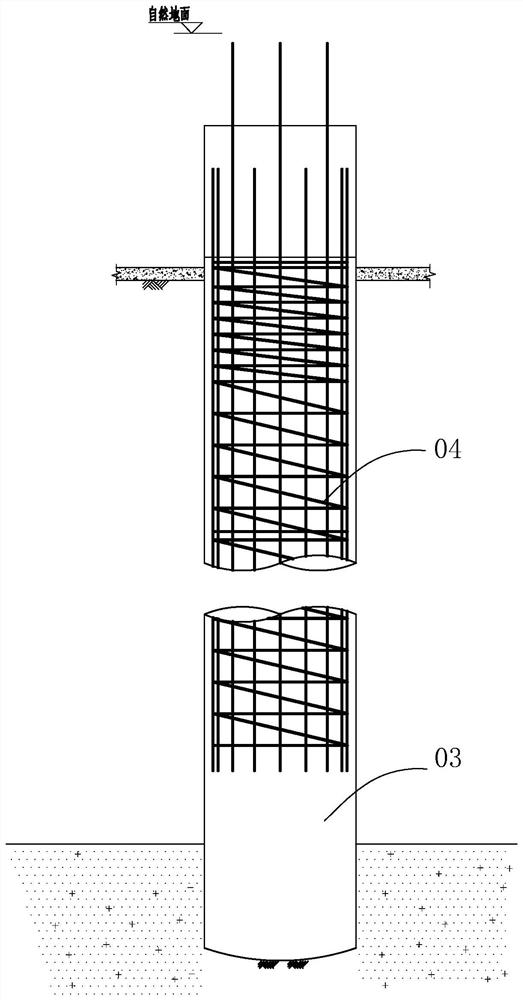

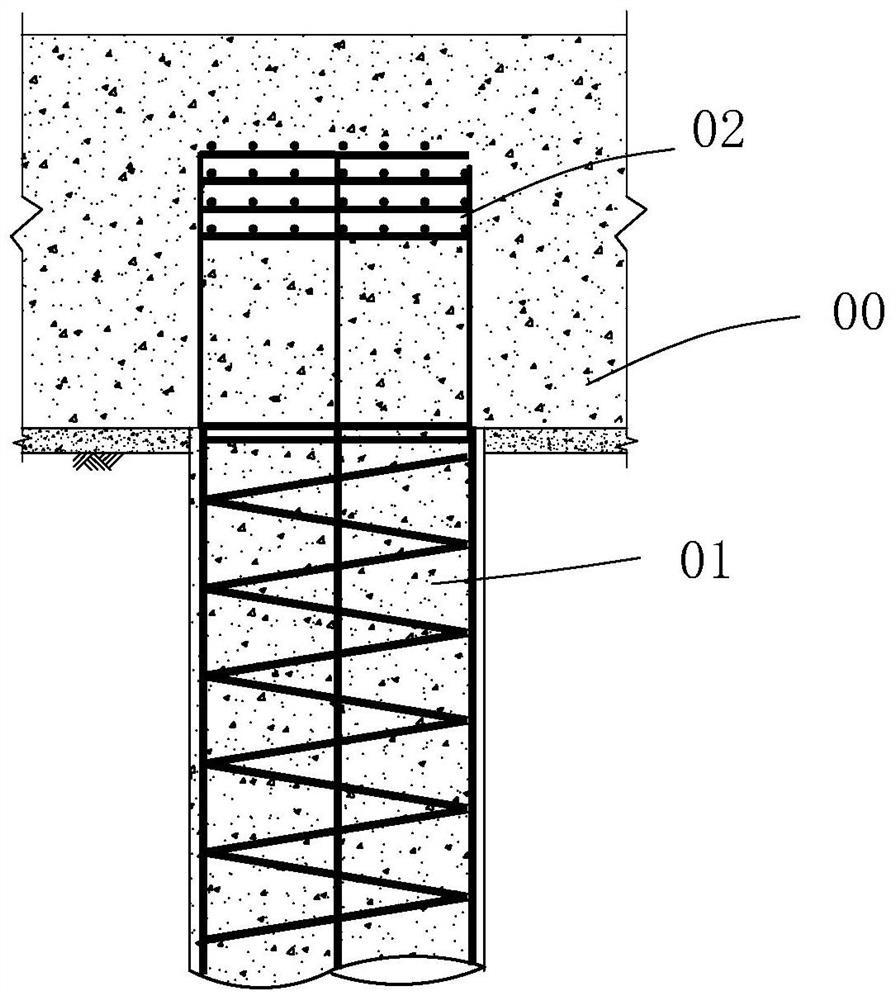

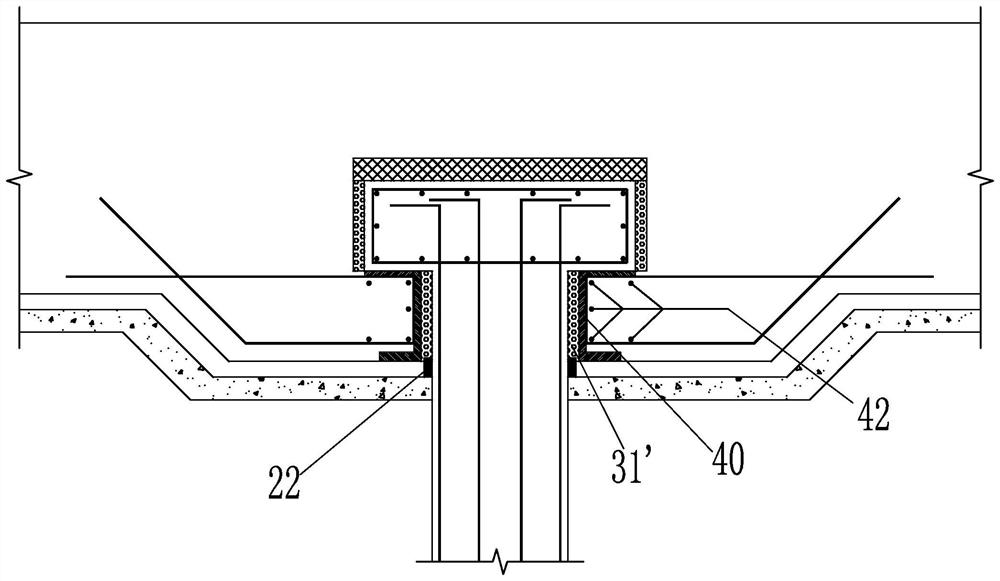

[0052] refer to Figure 3 to Figure 7 , the present invention, in conjunction with the above-mentioned accompanying drawings, introduces a construction method of a novel structure that is only used for uplift-resistant pile foundation flexible connection nodes, including the following steps:

[0053] S1. In the foundation of the construction site, use a drilling rig to form a hole 03, lower a reinforcement cage 04, and pour concrete to form an anti-floating cast-in-situ pile foundation 01. This step is the same as the drilling rig in the prior art, lowering a reinforcement cage, and pouring concrete to form an anti-floating cast-in-situ pile The construction process is the same, you can refer to figure 1 structure shown.

[0054] S2. Chisel off the height of the pile head fan slurry section to the design elevation (when pouring concrete, the top surface of the concrete is mixed with some mud, so that the strength of the pile head concrete cannot meet the design requirements a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com