Adjustable gripper assembly of knitting machine

A mechanical and knitting technology, applied in the field of adjustable gripper components, can solve the problems of fabric loop elongation, affecting fabric forming quality, affecting weaving work and fabric forming quality, etc., and achieving the effect of preventing fabric from floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

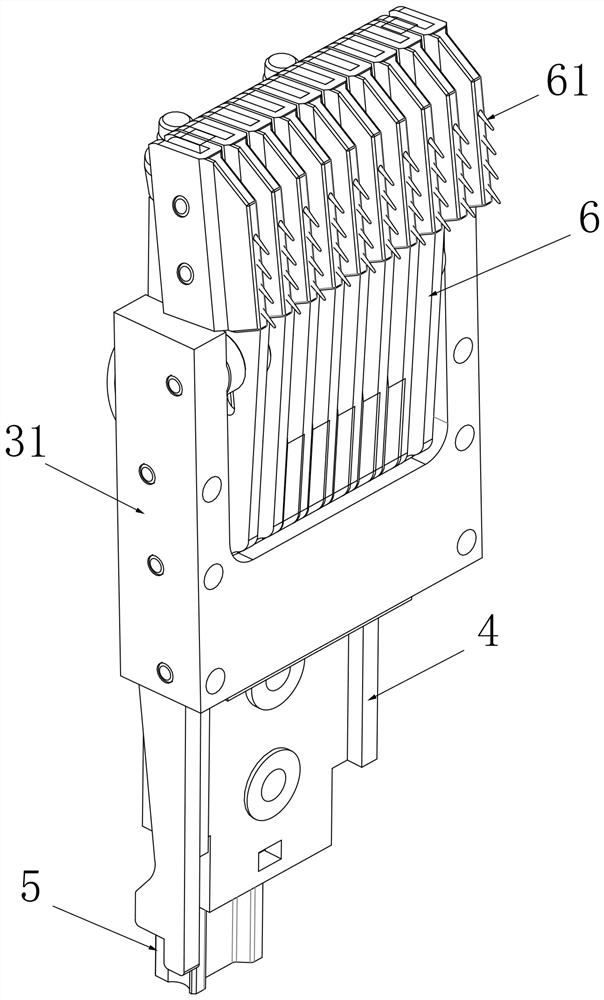

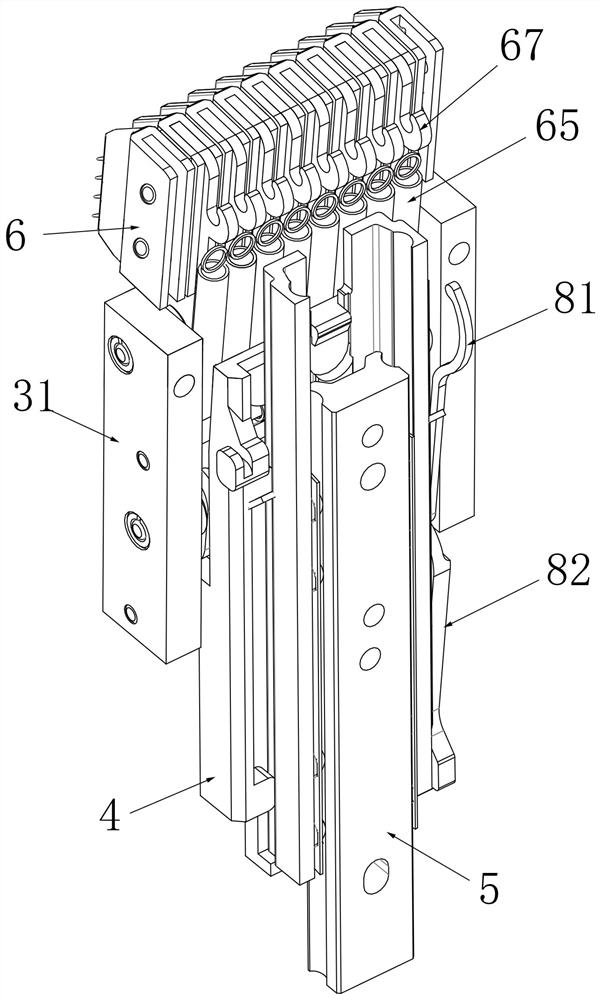

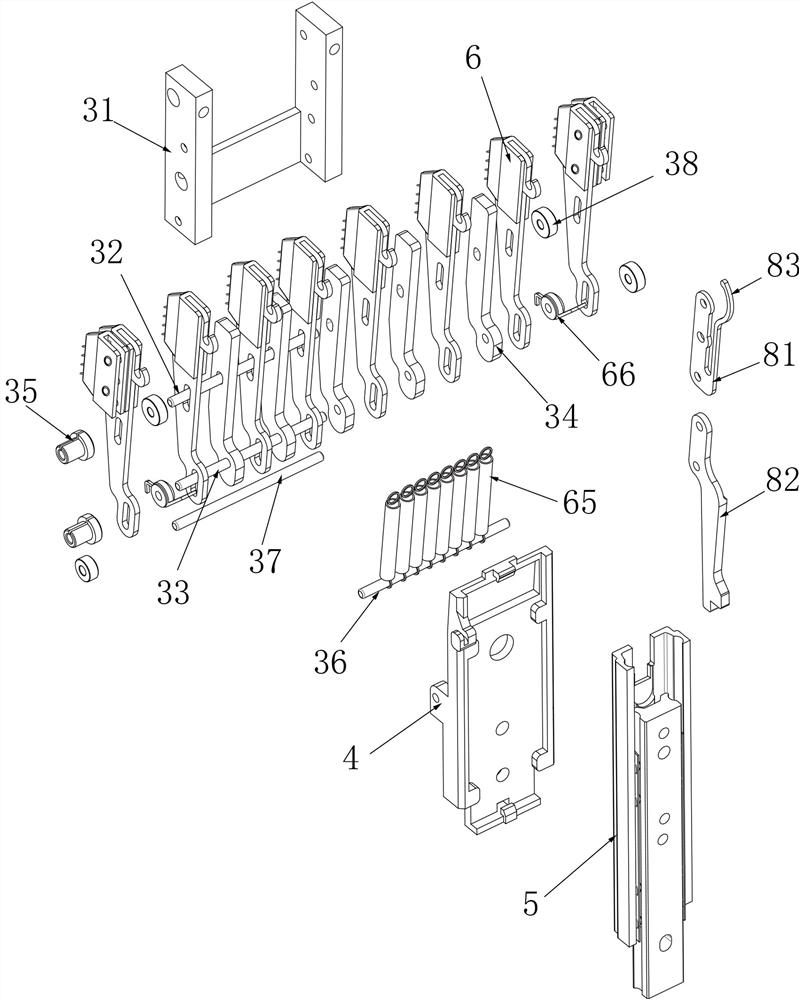

[0018] See attached picture. The pulling device described in this embodiment is composed of several rake-type pulling mechanisms on both sides, each rake-type pulling mechanism is independent, and several rake-type pulling mechanisms can be freely selected for action. Each rake-type pulling mechanism includes a claw assembly 3 , a lifting seat 2 and a fixed seat 1 . The gripper assembly 3 includes a gripper seat 31 , the gripper seat 31 and the lifting seat 2 are installed on the linear bearing seat 4 , and the linear bearing seat 4 and the fixed seat 1 are connected by a linear bearing 5 .

[0019] The gripper seat 31 is provided with a plurality of independent gripper pieces 6, and several needles 61 are arranged longitudinally, and are obliquely inserted on the gripper pieces 6 regularly; the front end of the gripper seat 31 is also provided with a guard plate 7, The guard plate is provided with a plurality of elongated slots for needle movement, and the guard plate 7 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com